Transforming Manufacturing with Machine Vision Technology

Discover the revolutionary impact of machine vision in manufacturing. Learn how integrating AI and machine vision enhances efficiency, quality, and safety in industrial automation, and explore the challenges and future advancements in this cutting-edge technology.

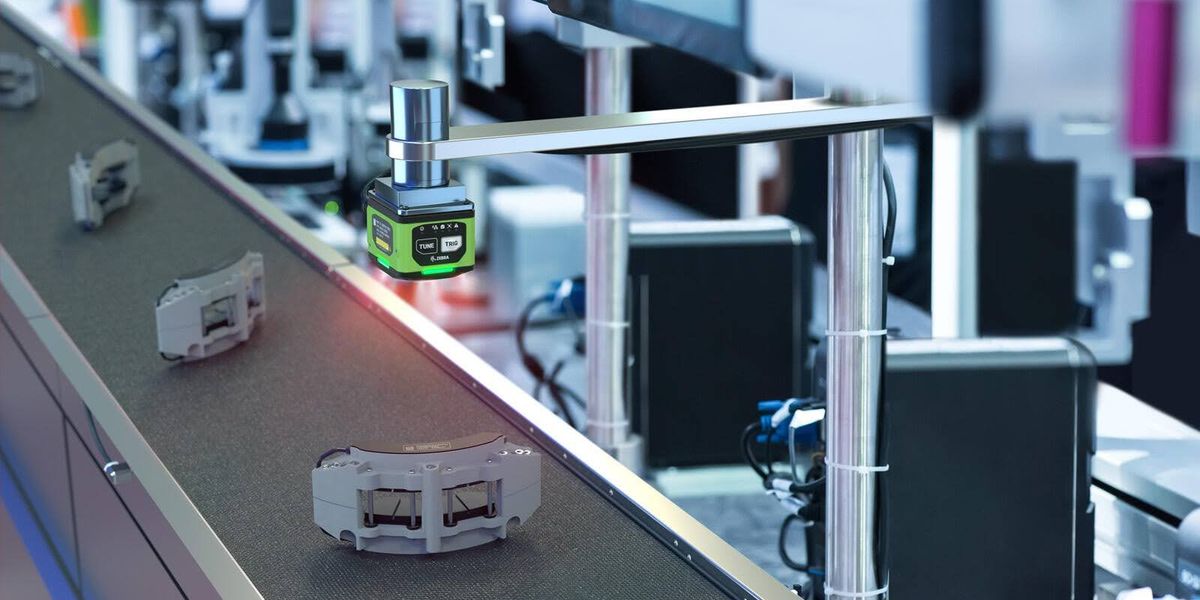

Machine vision represents a fascinating fusion of hardware and software designed to empower machines to 'see' and interpret the world around them. This technology, critical in manufacturing, automates tasks that require visual understanding, enhancing efficiency, accuracy, and safety on production lines. From guiding robots to inspecting products for defects, machine vision systems translate visual inputs into actionable information, fundamentally transforming industrial operations.

The evolution of machine vision is closely linked with advancements in artificial intelligence (AI). As AI technologies have progressed, they have significantly enhanced the capabilities of machine vision systems, enabling more complex and nuanced interpretation of visual data. This integration has been pivotal in driving Industry 4.0, the ongoing automation of traditional manufacturing and industrial practices using smart technology.

Augmented with AI, machine vision is an enabler of automation and a key player in creating intelligent, adaptable, and efficient manufacturing environments. The convergence of machine vision and AI pushes the boundaries of what's possible in industrial automation, leading to unprecedented productivity and innovation.

The Core Components of Machine Vision Systems

Machine vision systems are intricate setups that combine hardware and software to enable machines to 'see' and make decisions based on visual inputs. These systems play a pivotal role in various applications, including automated inspection, process control, and guiding robots, significantly contributing to industrial automation and robotics advancements.

Hardware: The Observational Components

The foundational hardware components of machine vision systems include cameras and sensors, which serve as the 'eyes' of the system. Cameras equipped with image sensors capture visual data from the environment. These cameras range from simple, compact smart cameras for specific applications to more complex multi-camera systems offering greater versatility and data collection capabilities.

Sensors are crucial for determining the system's specifications, such as resolution, directly impacting the amount of data collected and the system's ability to discern environmental changes. The resolution, defined by the total number of pixels in rows and columns, affects not just image clarity but also processing speed, with monochrome cameras often facilitating faster processing than colour counterparts due to simpler data.

Software: The Analytical Brain

On the software side, machine vision systems are powered by image processing algorithms and, increasingly, by deep learning and AI technologies. These software components are tasked with analysing and interpreting the captured visual data. The traditional approach to image processing involves predefined rules for analysing images, which can be rigid and limited in scope.

The Synergy of Hardware and Software

The interplay between the hardware's data collection capabilities and the software's processing power defines the effectiveness of a machine vision system. Adequate lighting and lens quality are also essential, ensuring the captured images are clear and detailed enough for accurate analysis. For example, the choice between backlighting and front-lighting setups can significantly affect the system's ability to capture usable data in real-world applications.

Implementing Machine Vision in Manufacturing

Implementing machine vision in manufacturing significantly enhances quality control, defect detection, and production efficiency. This technology integration facilitates a transition from manual to intelligent manufacturing, providing high detection accuracy, speed, and improved coordination.

Machine vision technology is pivotal in collecting information, detecting quality, positioning, automatic sorting, and intelligent monitoring within manufacturing. It addresses the challenges of poor quality, low precision, low efficiency, and high labour intensity traditionally associated with manual operations. Adopting machine vision in manufacturing accelerates production, elevates detection accuracy, and minimises the risk of accidents.

Enabling Algorithms for Object Detection, Identification, and Classification

The backbone of machine vision systems in industrial settings is a suite of sophisticated algorithms that enable object detection, identification, and classification. These algorithms leverage optical tools and computer technology to collect and process data, simulating human visual functions.

With the advancement of AI, machine learning, and deep learning technologies, machine vision systems have achieved higher accuracy and broader application scopes. These technologies encourage traditional manufacturing processes to become more intelligent, requiring expertise across various fields, including optical imaging, signal processing, image processing, and deep learning.

Current Trends and Future Directions

The evolution of machine vision technology is rapidly transforming the landscape of industrial automation, robotics, and beyond. At the forefront of this transformation is integrating 3D imaging and point cloud data, offering enhanced spatial analysis and enabling more complex applications. Let's explore the cutting-edge research and predictions for future advancements in this exciting field.

Integrating 3D Imaging and Point Cloud Data

In recent years, significant advancements have been made in deep learning techniques for processing 3D point cloud data. This has revolutionised applications in fields such as robotics and autonomous vehicles by allowing for detailed spatial analysis of environments. Techniques exist for various tasks, including 3D object classification, tracking, pose estimation, segmentation, and point cloud completion. Transformative methodologies like Pointr and SnowflakeNet have emerged, highlighting the potential for these technologies to evolve further and impact various domains.

Predictions for Future Advancements

Augmented Reality (AR) Applications: AR's immersive experience can benefit greatly from advancements in machine vision by providing more accurate and real-time interaction with the physical world. This could revolutionise medical imaging, retail, and education by offering more intuitive and interactive ways to engage with information and environments.

Further Integration with Robotic Process Automation (RPA): Machine vision technology allows robots to perform more complex tasks more efficiently and accurately. Combining machine vision and RPA could lead to significant productivity boosts from manufacturing to logistics by automating tasks that require understanding and interpreting visual data.

Ease of Use and Accessibility: There's a trend towards making machine vision systems more accessible and easier to use. Efforts are being made to develop "ease-of-use" and "no-code" solutions to democratise the technology, making it more accessible to non-experts.

Growth in 3D Imaging for Vision Guided Robotics: 3D imaging is no longer emerging but becoming a mature automated imaging offering. From bin picking to product palletizing, these solutions promise to expand the use of VGR by making it more user-friendly and applicable to a broader range of use cases.

AI and Deep Learning as Automated Inspection Tools: Deep learning has become a valuable tool for segmentation and classification in automated inspection. It enables the identification of images or features within images more intuitively, akin to human perception.

Practical Applications of Machine Vision in Industry

Machine vision technology transforms operations across various sectors, particularly in the automotive and electronics industries, by enhancing product quality and operational efficiency.

Automotive Industry

Machine vision is essential in inspections and robotic guidance in the automotive sector. Companies like Ford and General Motors (GM) use machine vision to ensure the safety and efficiency of manufacturing processes. Machine vision systems are employed for various applications, including flexible automation, model verification, and quality improvement. The technology offers significant advantages such as adaptable tooling, model verification on flexible lines, and in-station process control for immediate feedback. This enables manufacturers to uphold stringent quality standards and eliminate waste, ultimately contributing to producing a quality product.

Oil and Gas Industry

Machine vision is critical in inspections and robotic guidance in the oil and gas sector. Companies like Wipro are leveraging machine vision in several cutting-edge ways, including visual inspections of oil rigs, automated quality inspections, and remote monitoring of safety-critical assets. For instance, machine vision enables magnetic crawlers with cameras to inspect difficult-to-reach areas, such as great heights and remote locations within industrial plants. Robots equipped with machine vision can proactively detect internal cracks in gas pipelines, potentially saving millions of dollars by preventing failures. Moreover, these robots can grade the corrosion of pipes based on drone-captured images and videos, facilitating more preventive and cost-effective operations.

Manufacturing Industry

Machine vision systems are employed for various applications, including flexible automation, model verification, and quality improvement. The technology offers significant advantages such as adaptable tooling, model verification on flexible lines, and in-station process control for immediate feedback. This enables manufacturers to uphold stringent quality standards and eliminate waste, ultimately contributing to producing a quality product.

Electronics Industry

While the specifics on electronics were not directly covered in the sources, it's evident that the benefits and applications of machine vision in the automotive industry, such as inspection, quality control, and robot guidance, are also pertinent to the electronics sector. High precision and accuracy are essential in electronics manufacturing, where machine vision can identify defects, verify component placement, and ensure product integrity, much like in automotive manufacturing.

Key Benefits

Increased Efficiency: Automation of inspection processes and real-time decision-making capabilities speed up production lines and reduce manual intervention.

Reduced Error Rates: High-resolution cameras and sophisticated software in modern machine vision systems enable precise defect detection, minimising the risk of errors.

Enhanced Safety: In the automotive industry, ensuring the proper assembly of over 30,000 parts per vehicle is crucial for driver safety. Machine vision facilitates the flawless fabrication of each component.

Flexibility and Adaptability: Companies highlight the demand for more flexible automation as a driver for increased use of machine vision. The technology's adaptability allows easy integration into existing production lines, supporting model verification and quality improvements without needing hard-tooled custom fixtures.

Improved Quality: The ability of machine vision systems to provide feedback for in-station process control plays a vital role in quality assurance. By enabling the detection of defects at the source, these systems help maintain high-quality standards and reduce the cost and complexity of end-of-line repairs.

Machine vision technology continues to evolve, offering scalable and versatile solutions that cater to the growing demands of industrial automation.

Challenges and Considerations

Adopting machine vision technologies has several challenges and considerations that organisations must navigate to leverage their full potential effectively. These challenges include high initial costs, integration complexities, and the need for specialised expertise. By addressing these factors, organisations can better position themselves to take advantage of the numerous benefits that machine vision technologies offer.

High Initial Costs

Implementing machine vision technologies often requires a significant initial investment. This includes the cost of hardware such as cameras and sensors, software for image processing and analysis, and the infrastructure needed to support these technologies. While the costs of components and engineering have decreased, making the technology more accessible, the initial setup still represents a substantial financial commitment.

Integration Complexities

Integration involves ensuring compatibility between new and existing systems, configuring machine vision technologies to meet specific operational needs, and optimising performance within the current workflow. This complexity is compounded by the rapid pace of technological advancement, which introduces new standards and capabilities that systems must adapt to.

Need for Specialized Expertise

Organisations often need professionals skilled in both the technical aspects of machine vision systems and the specific applications within their industry. This expertise is necessary for designing effective solutions, troubleshooting issues, and updating systems to incorporate the latest advancements in the field. The challenge here is finding and retaining talent with the necessary skill set.

By proactively addressing these challenges, organisations can harness the power of machine vision technologies to drive innovation and competitive advantage in their operations.

Conclusion

The transformative impact of machine vision on manufacturing is undeniable. Machine vision has become a cornerstone of modern industrial automation through its ability to automate complex inspection tasks, enhance quality control, and drive efficiencies. Its application spans various sectors, providing unparalleled accuracy and speed in tasks once deemed challenging for automated systems. Machine vision systems minimise downtime, reduce waste, and ensure product quality by enabling more reliable and faster inspections, significantly improving manufacturing.

The journey of machine vision from a supportive technology to a pivotal component of industrial automation underscores its transformative impact on manufacturing. As we look to the future, continued innovation, coupled with strong partnerships between technology providers and manufacturers, will be key to unlocking the full potential of machine vision. Embracing these advancements will ensure that industries keep pace with modern production demands and set new standards for efficiency, quality, and innovation.

References

https://www.frontiersin.org/articles/10.3389/frobt.2021.627280/full

https://www.cognex.com/what-is/deep-learning/challenges-to-machine-vision

https://www.automate.org/vision/industry-insights/machine-vision-in-the-automotive-industry

https://www.automate.org/vision/industry-insights/machine-vision-in-the-automotive-industry

https://aimagazine.com/articles/machine-vision-enabling-the-factories-of-the-future