10 Water-Resistant Options for Your 3D Printed Parts: Materials & Post-Processing

This article reviews the different ways of getting water-resistant parts with 3D printing: materials, 3D printing processes and finishing options.

Water-resistance is essential for parts that will be exposed to rain and other moist weather conditions including constant contact with water such as water bottles. For 3D printing technologies, there are several factors to consider in order to get water-resistant parts: the material, the 3D printing process and the post-processing options.

3D printing water-resistant materials

Most 3D printing materials such as PLA can degrade when exposed to water over extended periods, while metals generally develop rust due to oxidation by water. Materials with good water resistance are classified as IP 67 and/or IP 68 according to the Ingress Protection Code.

The 3D printing materials listed below can be used to make water-resistant 3D models without too many surface treatments.

Polypropylene (PP)

This material is popular among food packaging bottles and containers. It is lightweight and repels water (hydrophobic) unlike other materials that absorb water over time.

Polypropylene is very flexible and has good interlayer adhesion with little gaps in between layers during printing. In addition to being water-resistant, it is also resistant to aggressive chemicals like acid and organic solvents. It has good heat resistance as well.

Suitable 3D printing technologies: MJF & SLS

Nylon PA 12

This material has good elasticity and high resistance to impact. Its resistance to chemicals, alcohols, fuels, oils and detergents are excellent. It has good stability to weather, and Ultraviolet light. PA12 offers some water-tight properties and a good price-quality ratio overall. However, it is not suitable for long-term contact with water and it needs some specific surface treatments such as epoxy coating to ensure better water-resistance.

Suitable 3D printing technologies: SLS & FDM

ABS

This material is excellent for water-resistant printing. ABS is a high impact resistant and tough material and has a glass transition temperature of about 105°C. It is highly resistant to aqueous, phosphorus and hydrochloric acids. However, it can be damaged by sunlight. It is commonly used in sprinkler lines and drain pipes.

Suitable 3D printing technology: FDM

Polycarbonate

Polycarbonate is a clear material with good impact resistance. It is an ideal material for baby bottles, refillable water bottles.

Polycarbonate is a tough and amorphous material with high impact strength, stability and good electrical properties. It has a wider temperature range of usage with a heat deflection temperature of 140°C.

Suitable 3D printing technology: FDM

PETG

PETG has significant chemical resistance, durability and good formability. It has strong water and moisture barrier as well as good impact resistance and is slightly flexible. This material has low forming temperatures making it popular in consumer applications.

PETG is commonly used for food containers and bottles for liquid beverages.

Suitable 3D printing technology: FDM

ASA (Acrylonitrile styrene acrylate)

This is an amorphous thermoplastic with improved weather resistance. It is widely used in prototyping in 3D printing due to its UV resistance and excellent mechanical properties. ASA has good resistance to chemicals and heat, with a glass transition temperature of 108 degrees.

Suitable 3D printing technology: FDM

Stainless Steel 316L / 1.4404

The relatively insignificant percentage of chrome in stainless steel makes it water-resistant. It is quite resistant to oxidation (rust). However, it can be damaged by chlorine-based water. It is typically used in food processing and laboratory equipment, heat exchangers, nuts and bolts.

Suitable 3D printing technology: DMLS

Comparing costs of parts productions using water-resistant materials

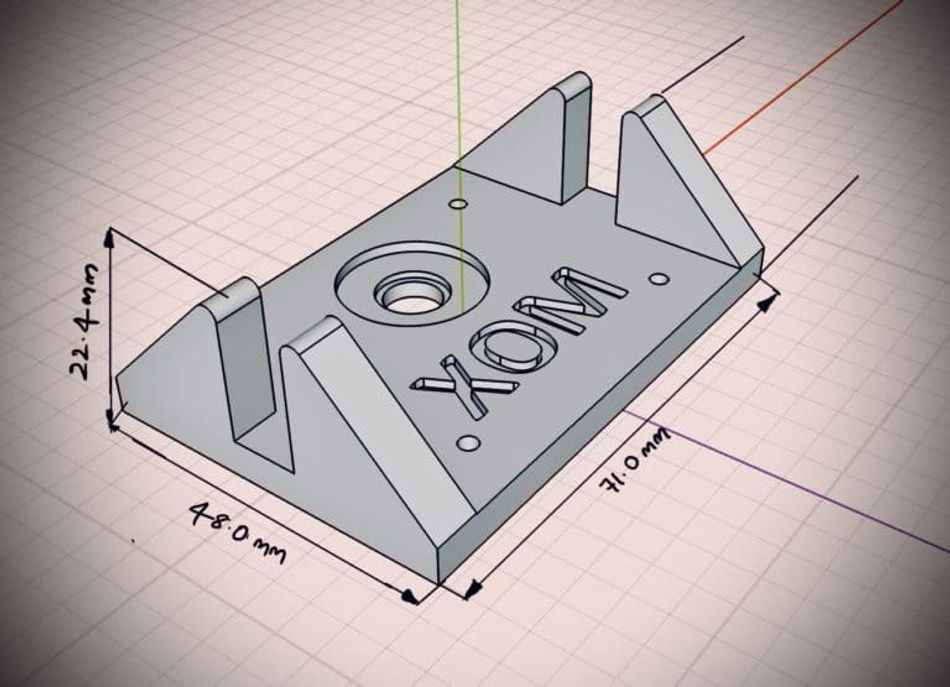

Let’s have a cost comparison of the production of parts using different water-resistant 3D printing materials from Xometry’s Instant Quote Engine:

| Material | 3D Printing Technology | Cost per one unit | Unit cost per 10 pieces | Unit cost per 100 pieces |

| Polypropylene | MJF | € 51.00 | € 11.72 | € 8.89 |

| Polypropylene | SLS | € 51.00 | € 31.57 | € 30.69 |

| Nylon PA 12 | SLS | € 20.96 | € 15.03 | € 12.73 |

| Nylon PA 12 | FDM | € 18.70 | € 10.35 | € 5.63 |

| ABS | FDM | € 9.13 | € 6.34 | € 2.57 |

| Polycarbonate | FDM | € 34.45 | € 25.89 | € 25.03 |

| PETG | FDM | € 10.84 | € 4.28 | € 3.32 |

| ASA | FDM | € 18.75 | € 6.60 | € 3.99 |

| Stainless Steel 316L / 1.4404 | DMLS | € 387.12 | € 294.83 | Price on demand |

3D printing water-resistant technologies

Fused deposition modeling (FDM), stereolithography (SLA) and selective laser sintering (SLS) are the best 3D printing technologies when it comes to the production of water-resistant parts. The following techniques can mostly be applied during the FDM printing process to achieve better water-resistant properties for the printed parts.

Wall thickness

Printing with a layer thickness of 0.15mm gives good print quality and good water-resistant parts. Increasing the thickness of the wall is one way to reduce porosity to water. The thickness of the wall may be increased by using a low layer height, solid infill and high temperature.

Increase shells

As a rule of thumb, the more perimeters added, the higher the chances of producing a water-resistant part. Indeed, the combination of 4 to 6 perimeters with a wall thickness of about 3mm works well for watertight parts. However, different materials have different perimeter limits hence the importance of considering the perimeter limit for the chosen material.

Higher printing temperature

Higher temperatures may give better layer adhesion between every layer. This improved bonding reduces the inter-layer gaps that may cause leakage of water.

Post-processing options to get water-resistant parts

Post-production processes are sure ways to ensure that your parts have the necessary water resistance for service.

Vapor smoothing

This process involves the blending of layers, removal of layer gaps and the tightening of the seal around the part. It is accomplished mainly by applying a solvent to a soluble print. It is worthy to note chemical solvents are somewhat peculiar to the materials.

This surface treatment is available for MJF and SLS technologies.

Epoxy Coating

Before the application of epoxy, it is vital to sand and polish the surface of the 3D part to make it as smooth as possible. This will ensure that it is properly primed for the application of the epoxy. Two-part epoxies are ideal finishing to obtain water-resistant 3D parts. The fluidity is just enough to sip into the cracks, voids, or gaps in the 3D print. The epoxy then hardens to produce a rigid layer that is water-tight.

Conclusion

Xometry Europe offers not only the materials and 3D printing processes but also the post-processing operations required to produce high-quality and functional water-resistant parts. Head over to our Instant Quoting Engine to explore our various materials, technologies, and finishing options and to upload your 3D model.