3D-Footwear: Visualize and Materialize

Taking an initial idea to the final product can be daunting. We strive to help you understand, with clarity, all the steps required to get there.

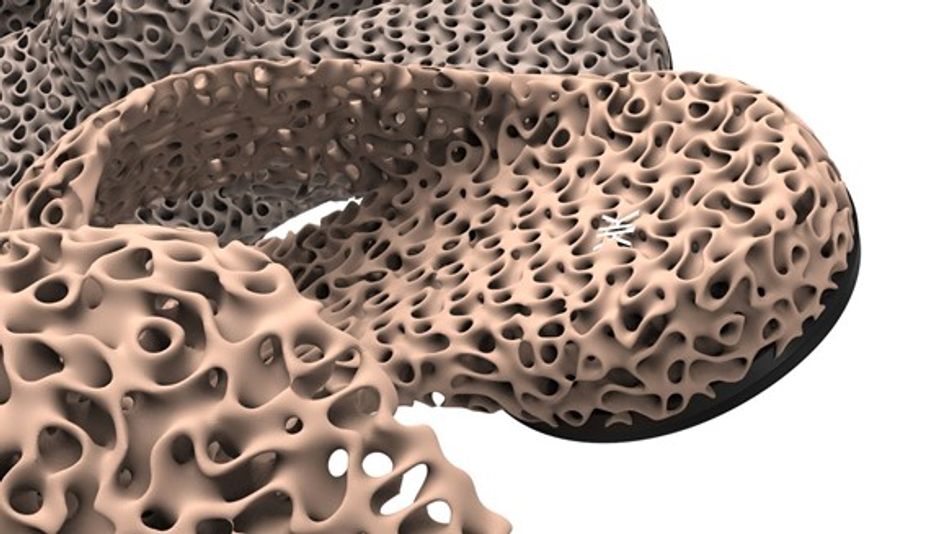

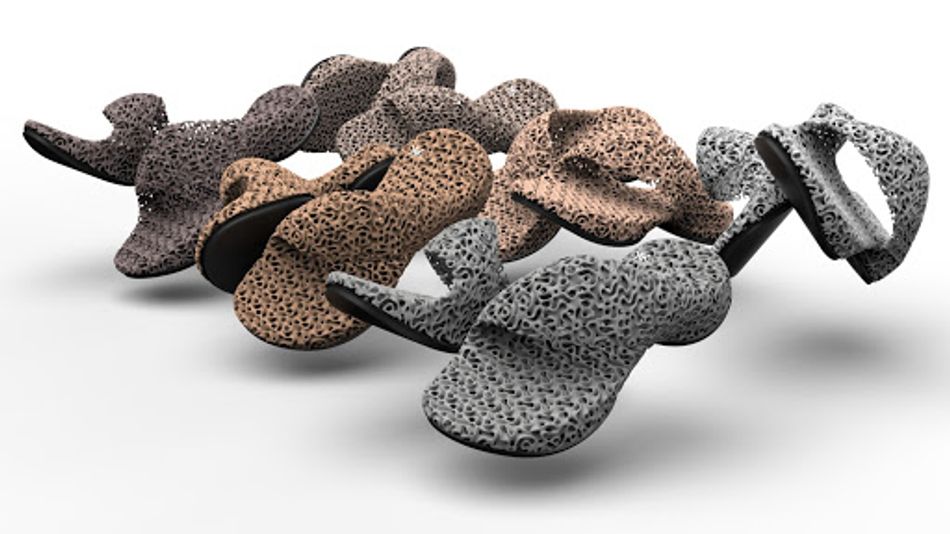

Sandal designed by Ica&Kostika and NJK Design seamlessly integrated with TPMS geometry

This article was first published on

ntopology.comThe capacity of advancement is expanded with greater fluidity in the design’s construction.

With the improvement of algorithmic and parametric 3D-modeling, the potential of designing footwear more efficiently and according to the individual’s needs continues to reach exciting possibilities. Force plate data taken from a runner’s landing can be imported to generate structures that vary in thickness and density with respect to regions of higher load. Even apart from user customization, the very nature of 3D-lattice structures offer benefits that are necessary in footwear such as energy return, stability, impact absorption, and reduced weight.

Starting a printing-based company or implementing additive methods as a new method of manufacturing could seem to be a costly, inefficient venture with those unfamiliar with the field. It is possible that for some businesses, additive manufacturing may simply not be the most ideal route of production, but it’s important to gain a strong understanding of the industry before coming to that decision; it’s possible that the hesitation to adopt additive technology is less due to actual disadvantages and more so a lack of proper guidance.

For one, companies no longer have to wait extended periods of time for mock-ups to be built overseas only to have large batches of finished products deemed unacceptable and money wasted. Now, production teams can create prototypes rapidly on-site for instant feedback, significantly streamlining the concept creation process. Products made through 3D printing would reduce both the time and cost of transporting parts, compress the length of supply chains, and offer immediate availability of past products just by pulling up its data file.

Personally, the most intriguing aspect is the ability to construct complex parts at a lower cost than traditional processes. Normally the concern of adopting additive methodologies is that the cost of producing an individual part is always the same, no matter if there are five or a thousand of it made, whereas for traditional methods the cost per unit decreases as the total number of units manufacturing increases. However, this isn’t the complete story because as the complexity of a part increases, there comes a point where the manufacturing cost actually becomes comparatively cheaper for additive manufacturing. So now, not only does design complexity open up new avenues for innovation, it could also come at a lower rate.

Now on the side of engineers and designers who are utilizing this technology, we strive to provide a creation process that connects the desired concept and finalized product as seamlessly as possible. The initial ideation process is often filled with awe-inducing aesthetics, grand endeavors, and limitless optimism. And rightly so, for every great product must start with a moonshot vision. However, every monumental abstraction is met with the limiters of technicalities and logistics that pull abstraction down to actualization.

This journey from concept to physical product is riddled with high doses of misdirected interpretation, baseless assumptions, and unexpected malfunctions. While the intrinsic benefits of the technology speak for themselves, what we also strive to address is the lack of awareness or proper guidance that was mentioned earlier. Not only do we want as little deviation between the initial dreams and materialized product, but also we want to expose, with crystal-clear clarity, all of the intermediate steps that are required to get there. We want a one-to-one.

Through 3D visualization, simulation, renders, and animations, we want to extract as much information as possible before any physical part is produced. Through generative design and algorithmic systems we want to formulate a design that is not only more efficient but also more personal; one that is driven by actual user data. Through a deeper understanding of materials and structures, we want to pinpoint what variables could be altered in order to generate the desired functional properties.

Revolutionary technology falls short of its grandeur if the high-tech experts are the only ones who are aware of its usage and capabilities. At first, we stated that ‘the capacity of advancement is expanded with greater fluidity in the design’s construction’, yet it seems that this only addresses the technological side of the story. More fittingly, the capacity of advancement is expanded with a greater comprehension of the design’s construction by all parties involved.

Watch the presentation that we give for the DfAM for Industrial Design series on November 3.

This article was first published on the nTopology blog.