3D Printer Cost of Ownership: What You Need to Consider

There are many factors to consider when purchasing a 3D printer, such as material capabilities, build size, purpose and future intention. However, one conversation that OEMs are afraid to have with prospects and clients is the true cost of ownership.

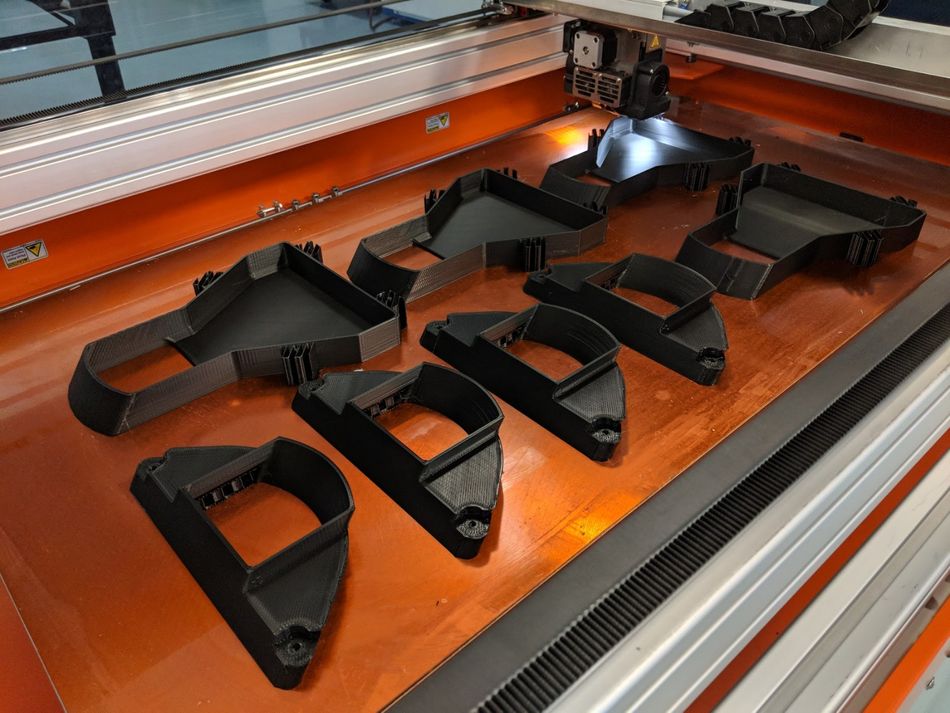

BigRep STUDIO

The Additive Manufacturing market continues to grow at an exponential rate. This includes a significant increase in adoption from industrial manufacturers while the 3D printing industry itself welcomes new hardware, software and material companies everyday.

There are many factors to consider when purchasing a 3D printer, such as material capabilities, build size, purpose and future intention. However, one conversation that OEMs are afraid to have with prospects and clients is the true cost of ownership.

What are the upfront costs associated with my machinery? Where can I purchase consumables, resin or filament? When will my equipment become obsolete? This article will address all these questions and more.

The goal is to provide you, the end user, with enough information so that you can be prepared to present solutions to your management. Unexpected costs or limited financial transparency will become quite problematic, especially if your organization is budget sensitive.

The 3D printing market is vast. There are hobbyist-level 3D printers available for amateur enthusiasts, and then there is industrial additive manufacturing equipment used by engineers and professionals. Hobbyist-level 3D printer prices range between $200 - $7,500 with basic printing capabilities and materials. The industrial-grade printing equipment has a much broader price range, $25,000 - $500,000, that is much more technologically advanced.

Part One: Capital Equipment Expenditures + Purpose

Regardless of company size or department budget, capital equipment expenditures over $50,000 will always be scrutinized. If it doesn’t fit on a corporate card then you will most likely be required to justify the purchase. And let’s be honest, your name will forever be connected to that piece of machinery once it’s installed—so it’s important to do the homework and make a good decision. In Part One, we will dissect the cost of AM equipment, and its purpose.

Industrial additive manufacturing equipment (operating with thermoplastic materials) can range from $25,000 to $500,000 depending on a variety of factors. This includes the size of the machinery, capability, reliability, ease of use, material compatibility and even brand name recognition. That’s a lot to keep track of.

For example, larger platform printers require robust servo motors and high-performance components to remain reliable and repeatable for users. Additionally, printers with advanced material capabilities operate with controlled heating chambers that will undoubtedly raise the cost of ownership and may be unnecessary for your application. You may be asking yourself, how do I determine which printer is the right one for me?

Is your department purchasing AM equipment for prototyping or production applications? What does your current process look like from a time and cost perspective? Who will be managing the machine? Analyze your current prototyping/production process and identify AM ready parts – meaning which parts are too expensive to outsource or are too complicated with traditional machining. AM provides inherent values when it comes to designing, so understanding the intention and purpose of your equipment will help determine the return on investment.

Recommended reading: 3D Printer Cost of Ownership: What You Need to Consider

For example, assembly line facilities have historically used metal parts for jigs and CMM fixtures simply because that was the only material available to them at the time. 3D printing with PLA plastic has become a viable alternative because it’s less expensive and lighter weight. Understanding the costs associated with traditional processes or parts helps determine the savings with 3D printing and ultimately, justify the ROI. The industry standard for equipment ROI is typically 18-24 months.

Part Two: Service Contracts, Consumables, + Post Processing

The equipment cost is just one piece to the printer acquisition puzzle. Purchasing a service contract for an expensive piece of machinery is commonplace in every industry, but AM is unique when it comes to consumables and post processing technologies. Almost every 3D printing technology comes with proprietary materials and a recommended solution for support removal.

The best estimate for an equipment service contract is between 15-20% of the overall cost. Indicating that $100,000 3D printer may require a $20,000 annual service contract. Much of this is dependent on equipment reliability and complexity. However, the alternative of no service contract is having to purchasing replacement parts at a much higher cost so you’re left with trying to decide what makes the most sense for your business. It’s possible that your business has separate budgets for equipment and service so we recommend speaking to your finance team first.

Every 3D printer OEM offers proprietary consumables in resin, filament or pellet form. The question is compatibility and control. Some OEMs restrict users from using 3rd party materials and consider it a breach of service contract if they do. Those OEMs tend to charge more for their materials while suggesting that the printer is more reliable because of that. However, the industry is transitioning to an open platform concept that enables end users to operate printers with third party materials.

BigRep’s approach is unique because it makes both options available. Be confident to use our suggested filaments with predefined settings embedded in the slicing software or feel free to experiment with other material providers. We simply recommend to our users to reach out and ask about the options. Oftentimes, we have experience with many materials and can point you in the right direction.

Historically, support removal and post processing equipment in 3D printing wasn’t discussed. Yes, it’s the less attractive part of the industry but it’s impossible to ignore if your AM technology requires it. For example, many thermoplastic technologies use soluble support materials which typically requires an ultrasonic bath for removal. The size of your parts justifies the size of the support removal system, which increases the cost accordingly. Alternatively, some AM technologies use breakaway support structures which require manual removal and sanding. Ultimately, it depends on your application and what type of finish your part requires. It’s not uncommon for designers and engineers to paint, weld, bond, sand or coat parts for optimal look and feel. With each process comes costs—whether automated equipment or manual labor.

Part Three: Intangibles + Obsolescence

Okay, if you’ve come this far then it’s time to talk about the future of your 3D printer and how to maximize your investment. As previously mentioned, the AM marketplace is complicated and it’s challenging to discern which technology is right for you. After you have determined the purpose of your 3D printer and analyzed the cost of ownership, it’s likely that you will have several options to consider. There are so many competing technologies that exist; so which company, brand or product are you willing to commit to?

How long has this company been in existence? Who are the major investors? What are the equipment reviews and will the company provide access to users and references? There is no need to work in a bubble when there is a world of resources available. When it comes to intangibles like company reputation or service standards, never underestimate the user testimonial. The industry is constantly evolving, and it’s very common to see major partnerships between OEMs, material providers, research institutes, and industrial leaders. In 2021, we have seen several AM companies go public and multiple mergers. Take time to learn about the company you wish to invest in. After all, your name is going to be attached to the decision.

Obsolescence is a much trickier conversation, and is one of the major reasons why some companies are hesitant to adopt 3D printing. Technology is advancing faster than ever before, and no one wants to be left holding the keys to outdated equipment. How can your department proactively prepare for obsolescence? First, determine a realistic ROI and try to stay under a 24 month payback schedule, which will improve the printer’s profitability. Second, ask the OEM if they have upgrade paths or buyback programs — most organizations do and are willing to drive customer loyalty. Finally, build an internal or external network of users, customers and research institutes that want access to your equipment and would pay to do so. These are just a few examples of building purpose for your 3D printer and monetizing it as quickly as possible.

Conclusion

The industrial AM market is complicated and expansive. The technology exists to enable engineers to rapidly produce prototypes, increase new product development, and identify new methods or materials for production purposes so the cost is justified. The question is, what exactly are you trying to accomplish? There is an alternative mindset in the market to purchase equipment now and identify ways to use this machinery in the future. These businesses typically have the financial resources to make such acquisitions and the luxury to wait and see. For the rest of us, we must develop ways to justify equipment purchases and truly understand the costs associated. Every 3D printer available on the market was originally designed to solve a problem but now every printer is the ultimate solution—one size does not fit all.

Need help? Let us PROve it to you with a free ROI calculation and part analysis.