3D Printing in Defense: Applications and Benefits

UltiMaker’s ecosystem, including Digital Factory for remote print management, enables defense organizations to integrate 3D printing into their workflows effectively. In this article, we aim to outline the key benefits and some of the potential applications of 3D printing in defense.

This article was first published on

ultimaker.com3D printing is gaining increased traction in the defense sector as its unique advantages can be leveraged to provide fast, cost-effective manufacturing solutions.

With a wide range of applications, the ability to produce spare parts on demand, create custom tools and jigs, help streamline the maintenance workflow, and reduce logistical challenges associated with traditional supply chain alternatives.

UltiMaker’s ecosystem, including Digital Factory for remote print management, enables defense organizations to integrate 3D printing into their workflows effectively. In this article, we aim to outline the key benefits and some of the potential applications of 3D printing in defense.

Benefits of 3D printing in defense

There are 5 main benefits that offer key advantages for defense applications:

On-demand spare parts production

Traditional supply chains require stockpiling spare parts, which takes up space and can lead to long lead times if a part is unavailable. With 3D printing, essential components can be produced on-site, reducing downtime and ensuring mission-critical equipment remains operational.

A professional desktop 3D printer is a compact all-in-one additive manufacturing station that can be deployed in forward areas and is ready out of the box or with minimal setup.

Reduced logistical challenges

Transporting spare parts, tools, and equipment is costly and resource-intensive. 3D printing’s inherent advantage is that it minimizes this burden by allowing parts to be manufactured as needed, reducing the need for large storage facilities and complex resupply operations.

Wide range of materials

Modern 3D printers support a wide variety of materials, including high-performance composites and metal alternatives, making it possible to produce durable and functional parts suitable for demanding defense operations.

For example, the Royal Netherlands Navy and UltiMaker collaborated on an application to verify the material strength of a 3D printed link to lift a 12-ton tank. Not only did the part successfully withstand the test but it did so while being produced faster (it takes a lot less time to 3D print a solid 2 kg link than to manufacture it via traditional methods) but it was also lighter than traditional metal link.

Faster maintenance and repairs

Custom tools, components, and maintenance jigs and fixtures can be printed on-site, reducing the time required to keep equipment in service. For example, the Royal Netherlands Air Force uses UltiMaker 3D printers to create maintenance tools for aircraft, speeding up servicing operations.

For example, during the transportation of jet engines, certain openings need to be covered with a special cap. While normally expensive to purchase and with often high delivery times, with 3D printing they can be manufactured in as little as 2 hours per part.

Digital inventory and remote print management

Instead of relying on physical stockpiles, military units can maintain a digital inventory of spare parts accessible from any location via UltiMaker’s DigitalFactory. Prints can also be managed remotely, ensuring that necessary components are produced efficiently and delivered where they are needed.

The ability to manufacture components locally is especially beneficial in instances where traditional supply chains face difficulties due to unexpected rise in the demand for parts, bad weather, or adversarial denial.

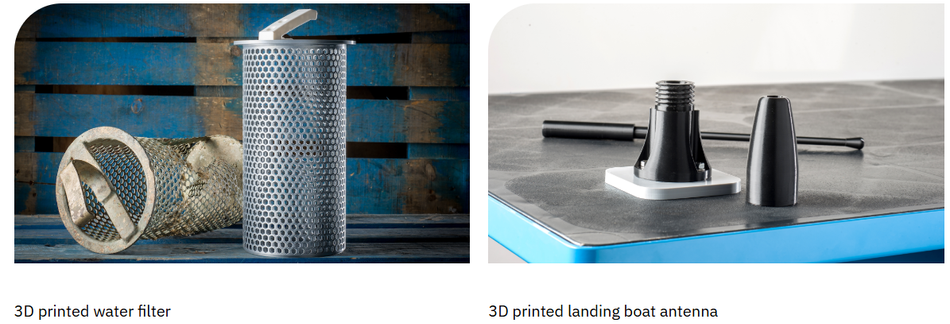

For example, naval ships can keep a small fleet of 3D printers onboard and only stock filament spools with various materials vastly reducing the weight and space that would otherwise be occupied by spare parts in storage. The Royal Netherlands Navy for example employs UltiMaker 3D printers on board its ships to print a variety of replacement parts like water filters, valve handles, etc. Using UltiMaker Digital Factory they could securely source the 3D files, monitor the printers, and ensure that their data remained protected throughout the process without compromising on accessibility.

Expanding applications beyond logistics and maintenance

While 3D printing has proven its value in defense logistics, maintenance, and supply resilience, its versatility can extend even further.

Beyond producing spare parts or mission-specific tools, additive manufacturing can make an impact in medical and humanitarian applications supported by the defense industry. Custom prosthetics, field medical devices, and protective gear can be 3D printed on demand ensuring that deployed personnel receive essential support in challenging environments as part of relief efforts.

By integrating 3D printing into defense workflows organizations can improve readiness, reduce logistical strain, and ensure adaptability in an ever-changing landscape.

If you want to know how you can leverage UltiMaker’s 3D printing ecosystem for your defense applications, don’t hesitate to get in touch with us.