5 key 3D printing applications

Adding desktop 3D printing to your workflow can make a big difference. Concepts and prototypes can be printed in a matter of hours. Multiple iterations produced quickly and cheaply. And complex ideas conveyed through a physical model that team members and stakeholders can see and touch.

Adding desktop 3D printing to your workflow can make a big difference. Concepts and prototypes can be printed in a matter of hours. Multiple iterations produced quickly and cheaply. And complex ideas conveyed through a physical model that team members and stakeholders can see and touch. So which industries have been the first to embrace this powerful technology?

Here’s a look 5 ways 3D printing can transform your business by improving productivity, reducing turnaround times, and giving organizations a competitive edge.

Product development

It’s vital to get your new product to market as quickly as possible. However, rushing the job can result in mistakes or not meeting customer expectations. A 3D printer lets you test iterations in a fast, cost-effective manner, adjust designs at almost no additional cost, and fine-tune your product in a matter of hours – not weeks.

Benefits include:

Better decision making: 3D print a range of concepts and select the best option during the early design stages

Check shape and form: 3D printing a basic model makes it easy to assess the shaping, size and overall proportions

Functional prototyping: Test your prototype in real conditions to check functionality, fit and manufacturability

Check appearance: Visual appearance can be appraised easily by designers, manufacturers and stakeholders

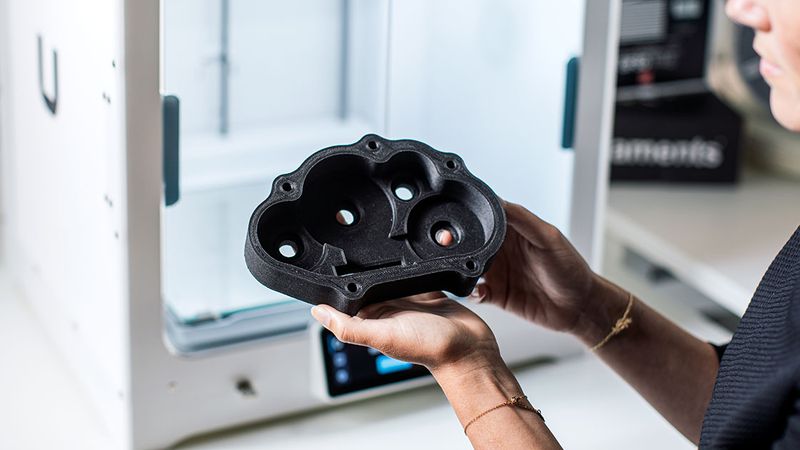

Manufacturing aids

Production efficiency is vital in a business environment – and time equals money. 3D printing makes it easy to produce jigs, fixtures, and other tooling in a short space of time. This results in less variation during assembly and fitting, faster machine setups, and a smoother production process.

3D printing your manufacturing aids ensures:

Better quality assurance: Test the accuracy and quality of your manufactured parts with precise gauges

Tools on demand: Whenever you need jigs, fixtures, or other tooling, you can 3D print them quickly, streamlining the production process

Better tool organization: 3D printed organizers are low-cost and fast to make, and promote better organization in the workspace according to 5S principles

Custom-made molds and patterns: It’s easy to make low-run injection molds or lost PLA casting to integrate into your workflow

End-use parts

3D printing can also be used to produce low-volume, customized end-use parts. This offers greater flexibility, enabling businesses to run small batches of parts without the risks involved of manufacturing a larger batch. There’s also scope for "printing on the spot" and creating products for the customer while they wait.

Here are other ways that 3D printing end-use parts can improve your business:

Create customized one-off parts: FFF manufacturing means you can create cost-effective bespoke printed parts for one-time projects

Make replacement parts: With a desktop 3D printer in-house, it’s simple to print replacement parts – cutting out the supply chain and purchasing processes

Run smaller batches: Small runs can be created cheaply and easily, without the risks associated with manufacturing in greater quantities

Decentralized manufacturing: Take the product to the customer by printing end-use products where they are; providing immediate access to the product they require

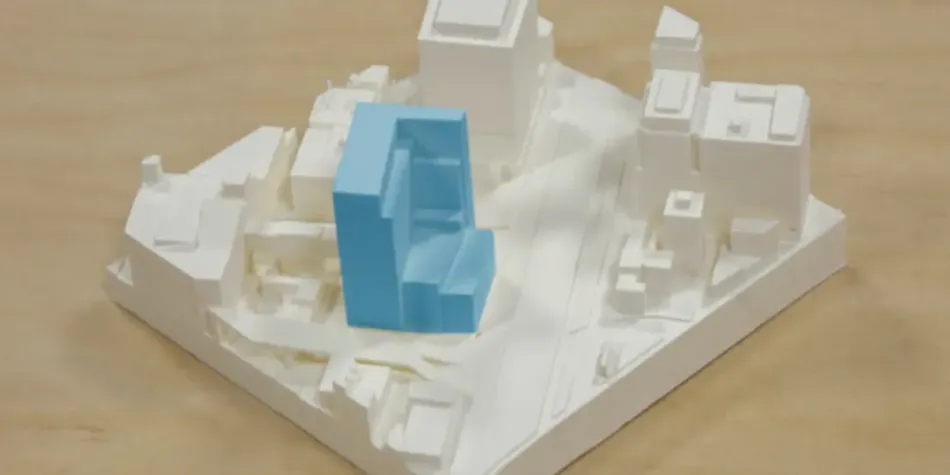

Architecture

Conveying complex architectural concepts to clients can be a challenge. 3D printing means that early designs can be evaluated, complicated ideas communicated, and striking architectural concepts showcased with ease. Model-making times shrink from months to days, and even complex geometries can be printed, offering architects even greater creative scope.

Other advantages include:

Easy production of concept models: Rough models can be printed quickly to establish the project’s direction in the early stages

Massing studies: Architects can view a building in its context, then scale up the model with modular 3D printed parts

Better presentations: 3D printed to-scale models result in a more impressive client presentation

Master plan creation: 3D printing not only offers fine detail, but large volume for planning scale models

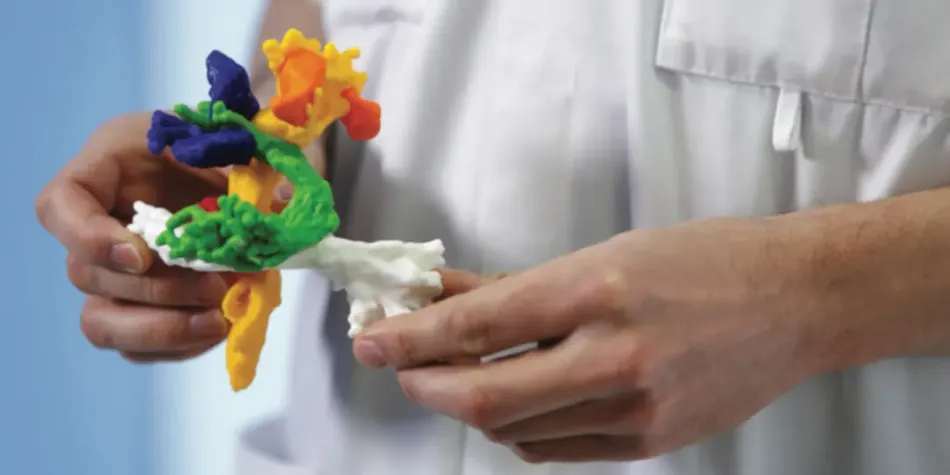

Medical

3D models mean that medical professionals can bring patient scans to life; identifying exactly what is required prior to performing a procedure. This results in less time under anesthetic for the patient, and reduced costs involved with the operation.

This personalized approach to healthcare also offers:

Improved surgical planning: Surgeons are well prepared prior to surgery, which impacts overall results

Better patient communication: A 3D model means that patients gain better understanding of the procedure – providing them with something they can see and touch

Medical instruments: Medical and research devices can be prototyped quickly and easily, and tools can be printed when required

Effective clinical training: By 3D printing anatomical models, students gain better understanding of anatomy and surgical procedures