Columbia Engineers Knit a "Blanket" of Sophisticated Radio-Frequency Antennas

Researchers are the first to use traditional flat-knitting techniques to fabricate flexible, lightweight metasurfaces--large-aperture antennas--that can easily be stowed and deployed for long-range communications

Media Credit: Jane Nisselson

This article was first published on

www.engineering.columbia.eduImagine taking the radio frequency properties of the dish antennas you see on rooftops and knitting them into a wearable garment -- a sweater or a blanket that is ultralight, portable, easy to fold up and stow away. Not having to use heavy, bulky satellite antennas would make communications much easier for those who live or travel in remote locations -- a lightweight, flexible antenna that can send information over long distances would be a useful tool for both the public and private sectors.

A Columbia Engineering team reports that they have used their expertise in metasurfaces -- ultra-thin optical components that can control the propagation of light -- and a low-cost, highly scalable flat-knitting platform to create radio-frequency (RF) communications antennas that are easy to carry and deploy. The study, led by Nanfang Yu, associate professor of applied physics and applied mathematics, was published in Advanced Materials.

Portable Knitted Antennas

Why knitting?

Most RF antennas, particularly highly directional array antennas like reflectarrays are planar, rigid devices. While these devices will likely always remain state-of-the-art in terms of pure performance metrics, they are often large, heavy, and unwieldy and can be expensive to manufacture. Researchers have been investigating ways to produce smaller, more flexible antennas, including inkjet printing or screen-printing directly on textiles, and embroidery. But these techniques are quasi-additive approaches in which a conductive material is added to an existing textile instead of being integrated into the textile during the fabrication process of the textile itself, introducing problems such as delamination, slip, or cracking of the metallic region, as well as issues of production scalability.

Yu’s group realized that what they needed to create was a high-throughput, inexpensive technique that directly integrates flat array antennas onto textiles. So they decided to study knitting and weaving, which, while being the most common approaches for fabricating patterned textiles, have not been explored as a way to produce complex array antennas with engineered electromagnetic responses.

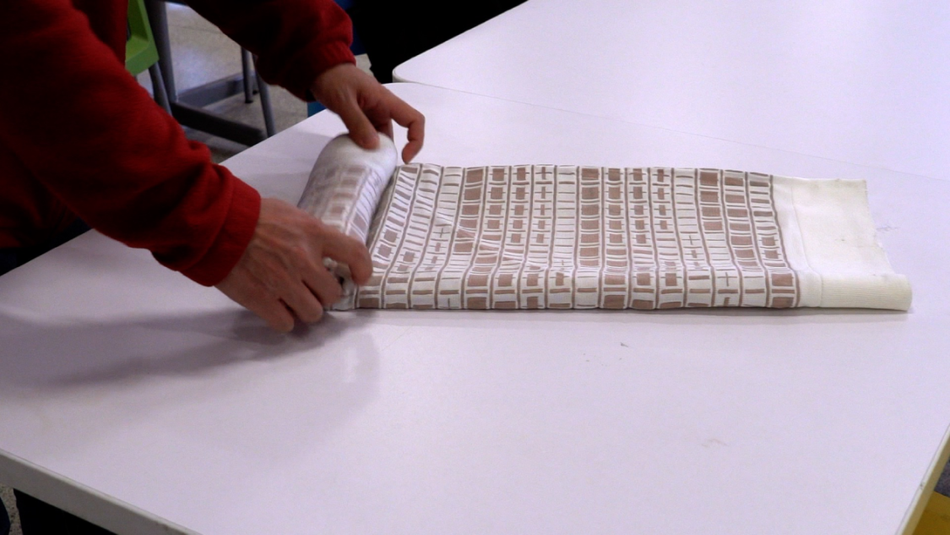

A Fair Isle approach

The researchers took a novel approach to fabricating flexible, lightweight centimeter-wavelength metasurfaces. They leveraged an old-school colorwork knitting technique called float-jacquard knitting (think Fair Isle sweaters) and used commercially available metallic and dielectric yarns with existing knitting machinery to produce two prototype reflectarray devices, a metasurface lens (metalens) and a vortex-beam generating device. In the float-jacquard knitting technique, two or more types of yarn are used to produce a pattern: a yarn is floated loose beneath the fabric when not used and transferred back to the frontside as needed to create the desired pattern.

By integrating the textile fabrication and antenna patterning into a single process, the team streamlined the fabrication process and alleviated common defects in fabric-based antennas. The group is the first to adapt flat-knitting techniques to incorporate antennas directly during the fabric production procedure – integrated fabrication – and able to do it at low cost and high yield on an industrial scale. For example, each of the prototype metasurfaces with a footprint of approximately one square meter was knit within 45 minutes. In addition, the flat-knit fabric devices withstood repeated washing and stretching on a frame.

“The float-jacquard knitting technique used for making our textile metasurfaces is exactly the same technique that my mother used to make sweaters for me. I still remember a purple sweater I wore as a kid that had a row of white cats across the chest; I remember that when I inspected the inner side of the sweater, I saw white parallel yarns – the floats,” said Yu, a pioneer in researching nanophotonic devices like metasurfaces.

He noted that these complex RF antennas can be readily produced by existing infrastructure: “We can leverage the very old and very well-established knitting industry to fulfill some of the needs of modern telecommunications. The facile and scalable nature of the fabrication approach means these devices could be inexpensive, ultra-lightweight, flexible variants of sophisticated radio-frequency communications antennas.”

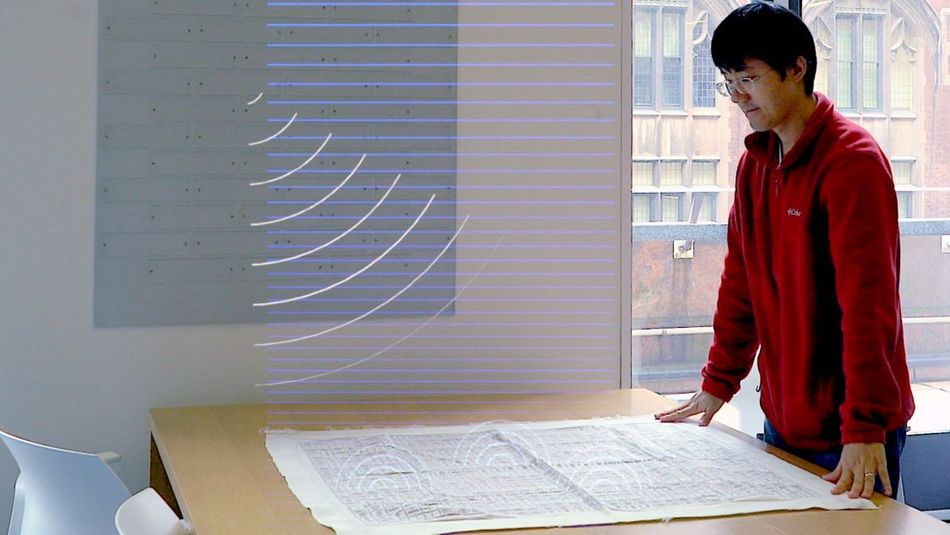

The results

The researchers showed experimentally that when the metalens operates as a receiving antenna, it focuses an incident centimeter-wave into a tight (diffraction-limited) focal spot, and that when it operates as a transmitting antenna, it converts the divergent emission from a horn antenna (a common RF source) into a wave with planar wavefront – a highly directional beam.

They also demonstrated that more complex wavefront shaping tasks can be accomplished: the vortex-beam generating metasurface produces a vortex beam – a beam with a corkscrew-shaped wavefront. Because of the peculiar wavefront, the vortex beam can carry an independent channel of information, thus a vortex beam and a beam with planar wavefront used together can make a communications channel twice as efficient.

Next steps

In future efforts, the researchers will explore modern knitting techniques – there are at least a dozen varieties – and knitting machines to realize more complex multi-functional designs – fabrics with combined designer electromagnetic, electronic, and mechanical responses. This could be used to engineer hinge points or folds, and electronic circuits into a fabric, which could be actuated to further facilitate stowage and deployment or even switch between different electromagnetic functionalities.

The scalability of flat knitting ranks highly among all techniques used to produce flexible or rigid RF metasurfaces and reflectarrays: commercial flat-knitting machines are capable of producing textiles up to two meters in width and with no limitation in the length direction. The researchers will explore this advantage to create high-gain antennas with apertures several meters in diameter yet lightweight and stowable to be carried by satellites to communicate across vast distances.

“It’s important to stress that these devices were fabricated using commercially available off-the-shelf yarns and leveraging established fabrication techniques,” Yu said. “I am almost certain that communities of knitters can come up with ingenious ways to integrate aesthetics and functionality into a sweater – a sweater that can double as a WiFi signal booster.”

About the Study

Journal: Advanced Materials

Title: Flat-Knit, Flexible, Textile Metasurfaces

Authors: Michael J. Carter1,2, Leah Resneck3, Younes Ra'di4,5, Nanfang Yu1

- Department of Applied Physics and Applied Mathematics, Columbia Engineering

- Materials and Manufacturing Directorate, Air Force Research Laboratory, Wright-Patterson AFB

- Zeis Textiles Extension, Wilson College of Textiles, North Carolina State University

- Advanced Science Research Center, City University of New York

- Department of Electrical Engineering and Computer Science, Syracuse University

Funding: The study was supported by the Science, Mathematics, and Research for Transformation (SMART) Scholarship of the US Department of Defense award to Michael Carter, and National Science Foundation grant (ECCS-2004685), awarded to Nanfang Yu. Measurements were carried out in mm-Wave Characterization Lab at the Advanced Science Research Center, the City University of New York. Devices were fabricated in the Knitting Lab (part of the Zeis Textiles Extension) at the Wilson College of Textiles, North Carolina State University

The authors have filed a provisional application for a patent with Columbia Technology Ventures based on the work reported in this article.