DLP 3D Printing: Understanding process and materials enables you to prevent production problems

DLP (Digital Light Processing) 3D printing uses photopolymerization to create 3D objects. Understanding the photopolymerization process can help you mitigate common problems that make your prints fail or that reduce print quality.

Image courtesy Origin.io

Introduction

3D printing technologies based on DLP printing (Digital Light Processing) are frequently used for fabricating complex objects without tooling and machining. DLP printing involves the light-mediated conversion of a liquid resin containing monomer or oligomer photopolymers to a solid object. This process leverages the versatility of polymer chemistry to make complex objects with programmable optical, chemical or mechanical properties. Versatility underpins the popularity of polymer materials within the 3D printing community, encouraging research in photopolymer chemistry and printing applications.

This video explains the process and working of DLP printers in detail - by Professor Bill Hammack, Department of Chemical Engineering, University of Illinois

Despite the growing enthusiasm for 3D printing in rapid prototyping applications, implementation in manufacturing environments to produce end-use parts has lagged. Common problems include setting and maintaining minimum specifications, specifically those related to material durability and weathering. Additive manufacturing methods rely on tight synchronicity between hardware, software and chemistry to achieve reproducibility at scale. This article highlights the role of polymerization in the co-development and simultaneous tuning of each component in the DLP process. By understanding the fundamentals of polymerization, developers can simultaneously tune process components, avoiding common pitfalls contributing to part defects, detachment, post-processing and weathering problems.

This article is sponsored by polySpectra, which makes functional materials for advanced additive manufacturing. PolySpectra CEO Raymond Weitekamp explained to Wevolver that they've spent thousands of hours and hundreds of thousands of dollars characterizing the thermomechanical properties of dozens of additive manufacturing polymers. For Wevolver readers they are providing a free specification sheet of their newest materials at www.polyspectra.com/wevolver

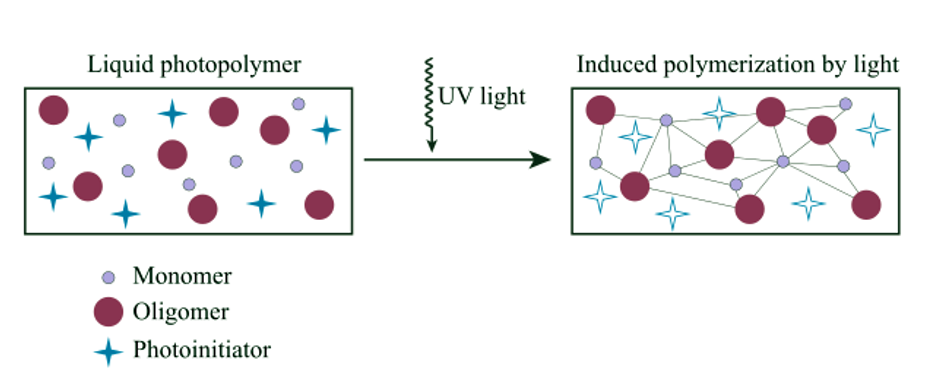

Photopolymerization: A multi-stage, dynamic process

A photopolymer is a polymer whose properties alter upon exposure to light. Photopolymers are a liquid mixture containing monomers and oligomers, which can be manipulated to achieve specified physical properties. The process of photopolymerization (also known as photocuring or photo crosslinking) describes the crosslinking of monomers / oligomers within the liquid resin to form a network polymer. This process typically occurs via cationic or radical mechanisms and is mediated by the addition of photoinitiators. Photoinitiators are molecules that convert photolytic energy into reactive species to activate polymerization through specific functional groups.

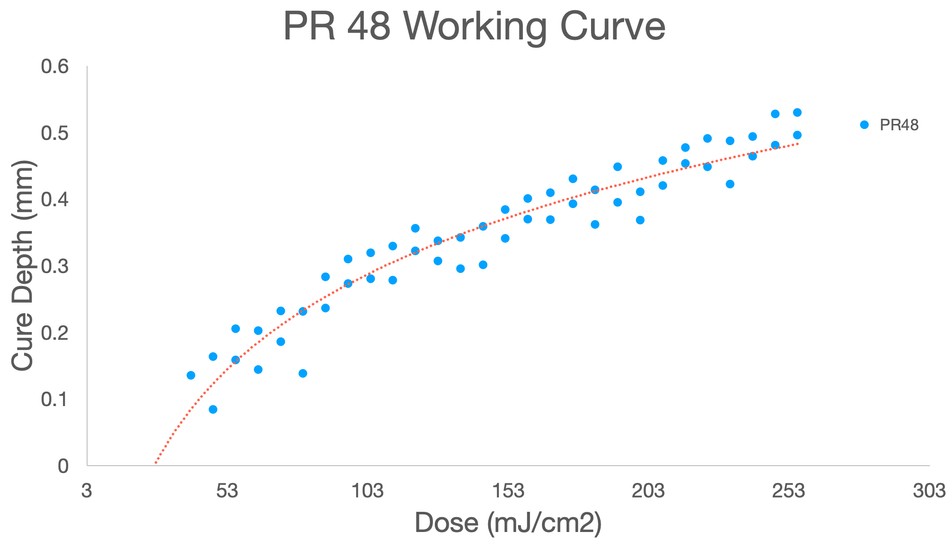

Photopolymerization is a multi-stage and dynamic process. Photopolymerization kinetics is described as a “working curve”, mapping cure depth (depth to which light induces polymer crosslinking) as a function of light exposure at different wavelengths. Critical exposure (Y-intercept on the working curve) is defined as the minimum light exposure required for the onset of curing. The behaviour of the photopolymer under specified light exposure conditions (wavelength, power, exposure time and velocity) affect the printing process. There are a wide range of photopolymers available, responding to wavelengths in the UV (190-400 nm), visible (400-700 nm) and IR ranges (700-1000 nm). Light of different wavelengths penetrate materials to different cure depths.

This video explains how the working curve impacts the 3D print and how to find the correct settings - by Autodesk Ember

Photopolymerization: A fundamental process in DLP printing

The dynamic nature of photopolymerization suggests that it is a non-binary process. In DLP printing, light is projected into the polymer resin forming a 2D image. This simultaneously exposes all the designated regions within a polymer layer. The overall printing time is reduced through compared to rastered stereolithography, due to the parallelization of the photocuring process. The projected 2D image is composed of pixels, which become voxels when translated into three dimensions. This has led to the misconception that DLP is an essentially digital binary processtechnology and that print resolution is purely a function of printer hardwarethe DLP optics. In reality, voxels contain photopolymers that are fluxing between stages of the photopolymerization process: going from liquid to their gel point and then on towards their full cross-linking density.

This video shows the impact of voxels on the 3D print and how printers can actually achieve resolutions smaller than the nominal resolution of the DLP projector - by Autodesk Ember.

This can influence the 3D printing process in several ways. Firstly, printing speed should be calibrated to account for photopolymerization kinetics. If not, voxels may expand beyond their digitally defined physical space, reducing feature resolution of the finished part. Further, photopolymerization may cause shrinkage in the hardened polymer. Shrinkage coupled with cycles of thermal expansion and contraction experienced during the printing process may induce stressinduces stresses on the part, . These stresseswhich can manifest in warping or layer splitting or separation in the finished object. Strategies to mitigate these effects include tuning both software and hardware to select appropriate exposure protocols (velocity and speed) and control environmental influences (temperature and humidity). Finally, the cure depth is an important parameter to consider when implementing a DLP printing protocol. Cure depth directly impacts the z- axis settings of the printer. It may also influence the selection of printing parameters such as print velocity.

Recommended reading: Digital Light Processing 3D printing explained

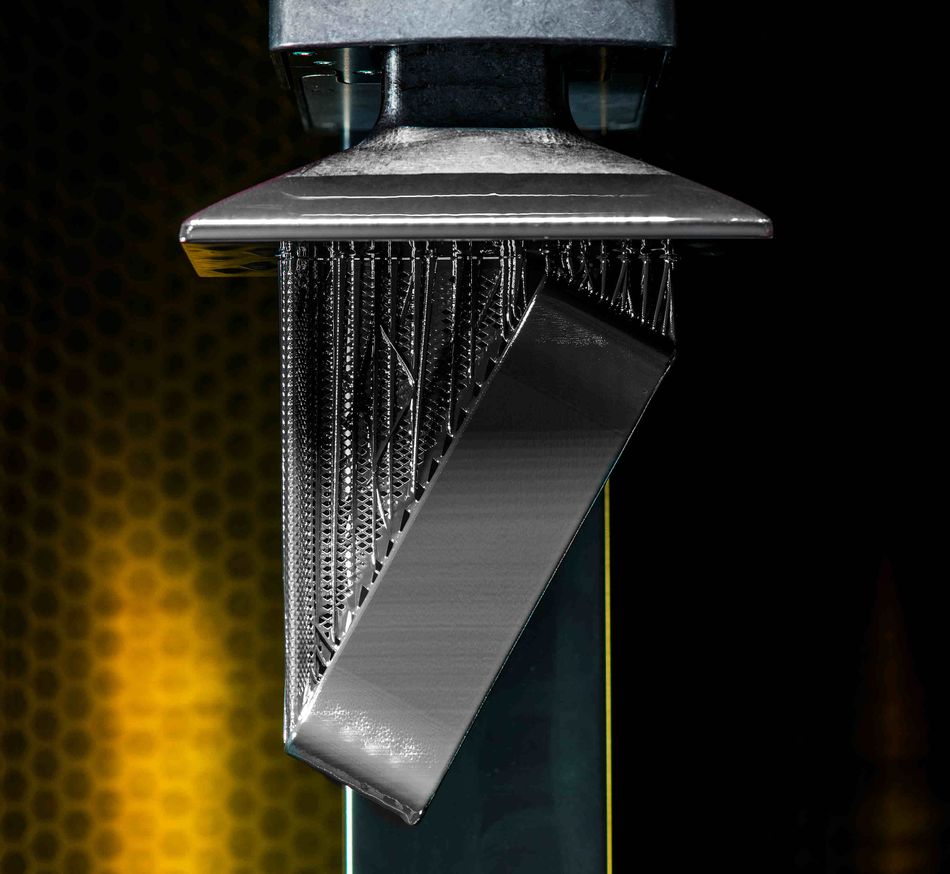

Detachment: Building and breaking interactions between materials and hardware

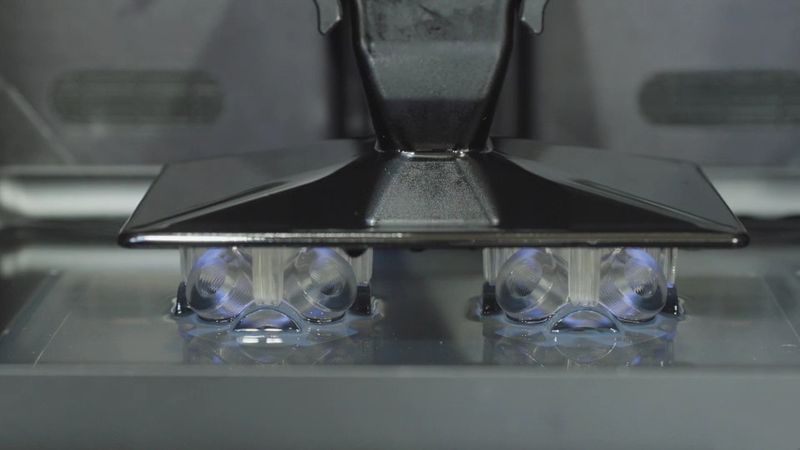

3D objects are rendered through the sequential hardening of photopolymer layers onto a substrate (known as a build plate). An essential step in any 3D printing process is the detachment of the finished part from the substrate. This step can prove problematic, as the printing process can induce suction forces, securing the part to the substrate. Numerous separation mechanics have been described to overcome these suction forces. Examples include tilting the resin tray and peeling the part off or using a sliding mechanism. Building the part on a flexible window, to which pressure may be applied to break suction forces is also a common method.

Building an oxygen permeable window within the substrate allows oxygen to access the photopolymer directly in contact with the substrate. This creates a depletion zone of inactive resin which does not adhere to the substrate, facilitating part removal. However, this method is only suitable for photopolymers which are quenched by oxygen, such as acrylates and methacrylates. An alternative strategy is to modify the viscosity of the liquid photopolymer resin. Low viscosity solutions enable higher printing speeds and concomitant reduction in the suction forces adhering the part to the substrate. This highlights an important aspect of 3D printing; the relationship between the photopolymer materials and the design of the printer hardware. It is widely recognised that surface adhesion is important to provide a foundation for the object to build upon. Consequently, the materials within the hardware and the finished printed object should be compatible.

Post-processing: The significance of photopolymerization in scaling production

DLP printing found initial application as an instrument for rapid prototyping in research settings. Introducing DLP printing into manufacturing settings has been slower due to problems with scaling production, reproducibility and part quality. The co-development of printing processes and materials is not only critical during the initial build process. Photopolymerization kinetics also affect post-processing of end-use parts. The acceptance of 3D printing into manufacturing settings has been restricted by extensive post-processing requirements including:

- Removal of the support structure (onto which the part is fabricated).

- Part cleaning to remove debris and residual materials.

- Post-curing (usually thermal or optical) to completely harden certain materials.

- Part finishing (such as sanding, painting or varnishing) to remove the “boxy” surface finish characteristic of DLP printing.

Rinsing off resing, removing support, and curing with UV light. Source: Formlabs

Post-processing steps are often performed in small batches under carefully controlled conditions. These processes can be difficult to automate, adding substantial time and cost to the production process. Advances in automation are ongoing, with some companies utilising robotics to automate assembly lines integrating 3D printers with post-processing equipment. Advances in printing hardware and software enabling automated monitoring could enable DLP printing at scale. However, the widespread implementation of automated processing lines has yet to be realised. Post-processing requirements are heavily dependent on photopolymer characteristics, with some materials requiring more extensive modification than others. Strategies to streamline operations should include selecting materials with limited post-processing requirements yet withstand weathering processes to maintain durability.

Conclusion

The combination of pivotal developments in 3D printing hardware, software and materials has paved the way towards the implementation in prototyping and manufacturing. With an increased awareness of the importance of co-developing each component simultaneously, the development of new applications for 3D printing of end-use parts is slowly becoming a reality. The relevance of DLP printing in the manufacturing sector will depend heavily on the ability to cost-effectively produce end-parts that are durable. The dynamic nature of photopolymerization continues throughout the lifetime of a part. The weatherability of hardened polymers is an important determinant of part durability, specifically the ability to maintain toughness and impact strength over time. By understanding the kinetics of photopolymerization and thermodynamic properties of the resulting polymer networks, developers can select materials to mitigate common problems, yet maintain desired properties throughout the lifetime of a part.

This article was sponsored by polySpectra. polySpectra makes functional materials for advanced additive manufacturing in Berkeley, California, USA. They use light-activated catalysts to 3D print advanced functional materials. Polyspectra's platform enables them to deliver materials with a broad spectrum of tailored properties from a single chemical system.

For Wevolver readers polySpectra is providing a free specification sheet of their newest materials at www.polyspectra.com/wevolver