ERIKS: Leveraging 3D Printing to Improve Manufacturing Processes

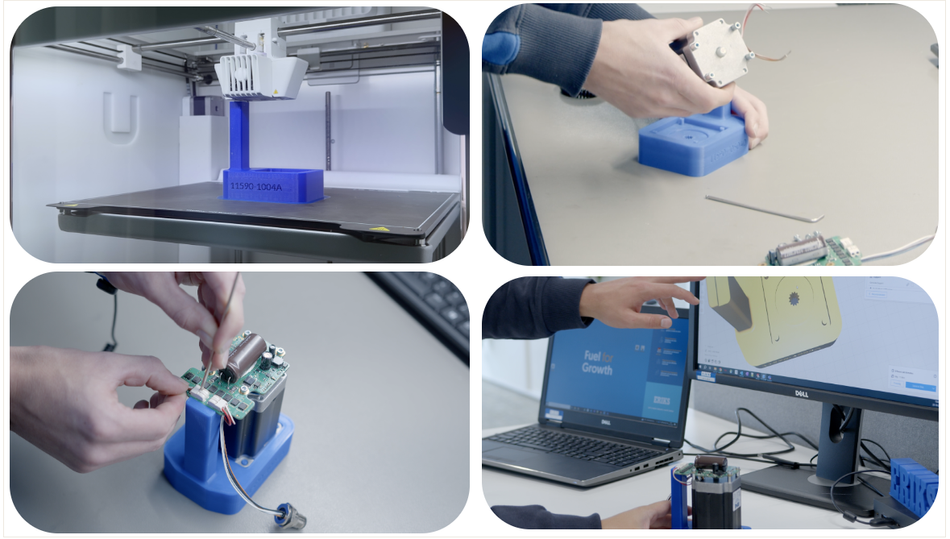

The majority of ERIKS 3D printers are dedicated to prototyping, customized jigs, fixtures, and tooling for production or maintenance purposes.

This article was first published on

ultimaker.comEstablished over 80 years ago, ERIKS maintains its industry leadership position by embracing cutting-edge technologies, like the UltiMaker 3D printing ecosystem, to meet the evolving needs of its diverse customer base. With more than 5,000 skilled colleagues in 15 countries, ERIKS is a multi-product specialist that provides a wide range of high-quality mechanical engineering components and services.

ERIKS has been an early adopter of 3D printing, incorporating it into various aspects of its operations, from jigs and fixtures to production parts. ERIKS places a strong emphasis on its lean manufacturing practices to create more value for customers with more efficiency, better quality, and fewer resources. What sets the company apart from its competitors is its commitment to quality and precision, evident in its decision to utilize 3D printing in clean manufacturing facilities. Notably, ERIKS achieved a milestone by certifying the workflow to create food-safe printed parts, positioning it as one of the pioneers globally.

The Reliability and Longevity of UltiMaker 3D Printers

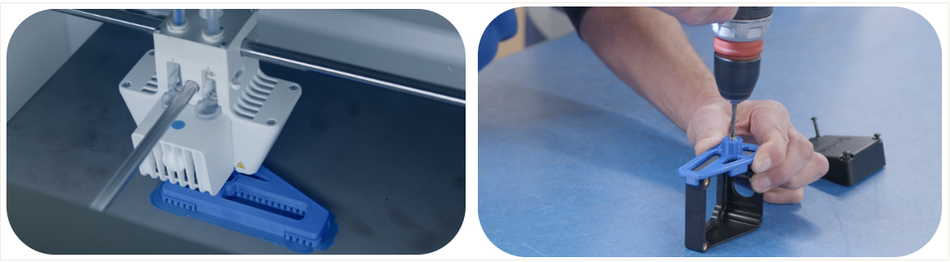

The majority of ERIKS 3D printers are dedicated to prototyping, customized jigs, fixtures, and tooling for production or maintenance purposes. Over time, the company has embraced the use of 3D printing for end-use parts, leveraging a variety of materials to meet specific requirements such as heat resistance, food safety, or EMD safety.

Job van de Sande, Head of Engineering at ERIKS, notes the versatility of 3D printing, enabling the production of flexible or rigid components tailored to diverse applications, including optimizing assembly or production processes, quality tools, and safety equipment.

Van de Sande emphasizes the significance of UltiMaker in their 3D printing journey, stating,

We made UltiMaker the platform of choice for FDM 3D printing at ERIKS. Now, we have expanded our fleet of printers to around 25 across 10 different teams in six different countries.

ERIKS employs various UltiMaker printers across the S series, including the latest UltiMaker S7 3D printer. The reliability and future-proof nature of UltiMaker have been crucial for ERIKS, ensuring that their investment in printers remains viable long-term.

Van de Sande commends UltiMaker's reliability and longevity, stating,

It’s very important that the printers we buy today are still usable five years from now. And thanks to the constant updates, for example, in firmware, we have been able to still utilize the entire fleet of UltiMaker printers that we bought over the years.

A Smoother, Faster, Better Process with 3D Printing

Jan Brabander, Product Manager at ERIKS Industrial Plastics in Ede, the Netherlands, highlights the significant role of 3D printing in their processes, especially for rapid prototyping and small series production, where cost-effectiveness and speed play crucial roles.

“During the development process, we can produce a part to make it easier to show to our production team or customers," Brabander notes. "We also use 3D printing throughout our processes internally, like production or quality control. For example, tools to assemble products, or to check measurements, or to make our process faster, smoother, and of better quality. We use 3D printing more and more for making end-use parts that are industrial grade and can be used in the machines or in the factories of our customers.”

ERIKS Industrial Plastics specializes in CNC machining and injection molding, but also incorporates 3D printing as a viable option for producing parts tailored to customer needs.

Van de Sande explains, "Whether they search for an application that needs to be heat resistant or food safe or EMD safe, 3D printing will work. But, also, when they look at more dynamic properties like having flexible or very stiff parts, they can really utilize the 3D printers for that." The Engineering Plastics production facility in Ede is designed to produce food-safe parts according to EC1935 and in compliance with GMP standards.

Van de Sande outlines a bottom-up approach for 3D printing adoption. Teams throughout ERIKS are encouraged to explore the potential of 3D printing within their production environments, gradually becoming part of the 3D Printing Expert Group. ERIKS has fostered a community where experts from different business units and locations converge to exchange ideas and knowledge, ensuring a holistic approach to 3D printing implementation.

The use of Trinckle, a software that offers parametric design and automation solutions, has further democratized 3D printing, enabling a broader group of individuals, who do not necessarily have engineering backgrounds, to create applications and utilize 3D printing. The software also offers a range of industry-standard preset fixtures, allowing ERIKS to streamline and accelerate the creation of 3D-printed applications.

Leveraging the Power of the UltiMaker 3D Printing Ecosystem

ERIKS has adopted the full UltiMaker 3D printing ecosystem, leveraging the UltiMaker Marketplace and Digital Factory Enterprise edition to establish a standard within the organization. Digital Factory provides a comprehensive solution for 3D printer management, allowing users to prepare, queue, print, and manage their projects remotely. The reliability and constant updates, including firmware and applications like Cura – the world’s most popular slicing program – ensures that ERIKS maintains a fleet of printers that remain usable over time, as well as enables the teams to expand the applications for 3D printing.

Security is a paramount concern for ERIKS and its customers. The deployment of Digital Factory Enterprise ensures secure operations, maintaining systems behind firewalls, while the Cura Enterprise edition facilitates collaboration with IT partners to ensure seamless tech stack integration. This comprehensive approach has allowed ERIKS to create a broad community of enthusiasts and experts, driving the widespread adoption of 3D printing.

Design Flexibility with 3D Printing

Brabander points out the benefits of 3D printing, stating, "The design flexibility is a significant advantage. There are less limitations in the production process. Also, it’s very fast."

The flexibility of 3D printing allows for rapid prototyping during development, streamlining communication with production teams and customers. ERIKS strategically chooses between various manufacturing/production technologies, considering factors such as series size, part quantity, lead time, and technical parameters to meet customer needs efficiently, and offering 3D printing as a solution when it aligns with the customer's needs.

Brabander emphasizes, "We're not pushing any type of technology. We can use 3D printing as a tool in our toolbox if that offers the best solution for our customer."

As ERIKS continues to integrate 3D printing into more locations, the company anticipates increasing cost and time savings, further expanding the technology's applications. Brabander continues, "The real benefit in our perspective is being able to produce better quality parts faster for our customers." The design flexibility and speed of 3D printing make 3D printing an optimal choice for certain applications.

Scaling up 3D Printing Capabilities

ERIKS' forward-thinking approach to 3D printing has not only improved its internal processes but has also become a valuable tool in meeting customer demands. The combination of UltiMaker's reliability, continuous updates, and comprehensive 3D printing ecosystem has propelled ERIKS to the forefront of innovation in manufacturing.

“With the development of more reliable and repeatable end parts, ERIKS has started to take steps towards aligning it with industry standards and making sure that 3D printing really becomes the alternative or even the preferred choice for new and exciting high-end applications,” said van de Sande.

Van de Sande concluded,

To scale up our capabilities within ERIKS, UltiMaker has already proven itself to be a reliable and flexible solution.