Five Manufacturing Challenges For Hardware Startups

Hardware startups have a unique set of challenges to overcome to be successful.

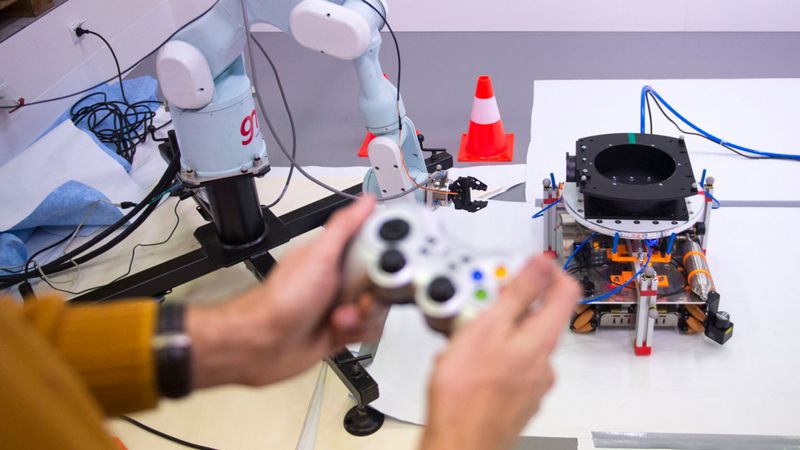

Image credit: ESA

Starting a business can be tricky. The challenges associated with starting a hardware business that requires manufacturing services are even more substantial. Traditional manufacturing is a capital-intensive process that requires high up-front and operating costs and a sophisticated set of interdisciplinary teams developing products. At its core, manufacturing is a technology-based industry that is constantly evolving as its processes improve. Therefore, a degree of agility is necessary to meet market demands. This flexibility, often naturally present in startups, can be helpful only if the company possesses the core elements of a mature manufacturing business. This article explores five main challenges hardware startups face and how cloud manufacturing can help them prevail.

1. Building the Right Supply Network

Startups are naturally hyper-focused on their products. This product-centricity is one of their greatest strengths. Equally important, however, is developing effective networks to supply the industrial components necessary to procure their products. This part of the equation consumes significant time and resources and can chip away at the go-to-market timeline and add expense.

A typical startup lacks the workforce to develop its product and a superb supply network simultaneously. The due diligence, negotiations, and back-and-forth with potential suppliers result in an exhaustive process—one that shifts the focus away from product innovation and revenue-generating activities. Larger companies can employ supply chain managers to perform this process successfully, leaving the engineers to focus on product development.

While software can be fine-tuned before, during, and after delivery, hardware needs to function right out of the box, complicating supply network management. A case in point is the failure of the Coin electronic credit card almost a decade ago[1]. The company worked with a supplier to manufacture only a fraction of what was later ordered after the technology was announced. Not only was the manufacturer unable to meet these demands, but the product also required tweaks that pushed the first shipment back by nearly a year. These circumstances resulted in faulty Coin cards in the customers’ hands and, ultimately, business shutdown[2].

How can cloud manufacturing help?

Cloud manufacturing enables a hardware startup to have immediate access to a network of audited suppliers and part manufacturers. Access to multiple suppliers that have the capacity and can accommodate running changes could have saved Coin from failure. Using a cloud manufacturing platform, companies are liberated from the request-for-quote processes, back-and-forth negotiations, and the development of a high-caliber supply network. Startups, in particular, benefit from skipping these painstaking, time- and resource-consuming tasks. A supply network available through cloud manufacturing provides them with better chances of success.

2. Product Quality

In addition to the supply network challenges, product quality tends to suffer in hardware startups. Smaller companies often lack the resources to find stable and capable suppliers quickly. They also may not have the time and team expertise to ensure quality materials. Even upon finding adequate suppliers, the initially low production volumes common for startups fail to warrant the attention needed. Companies with larger bulk orders tend to receive better customer service, preference for key talent, and, as a result, better overall quality from suppliers. Therefore, many startups grow frustrated, rightfully so, because their quality expectations are not being met.

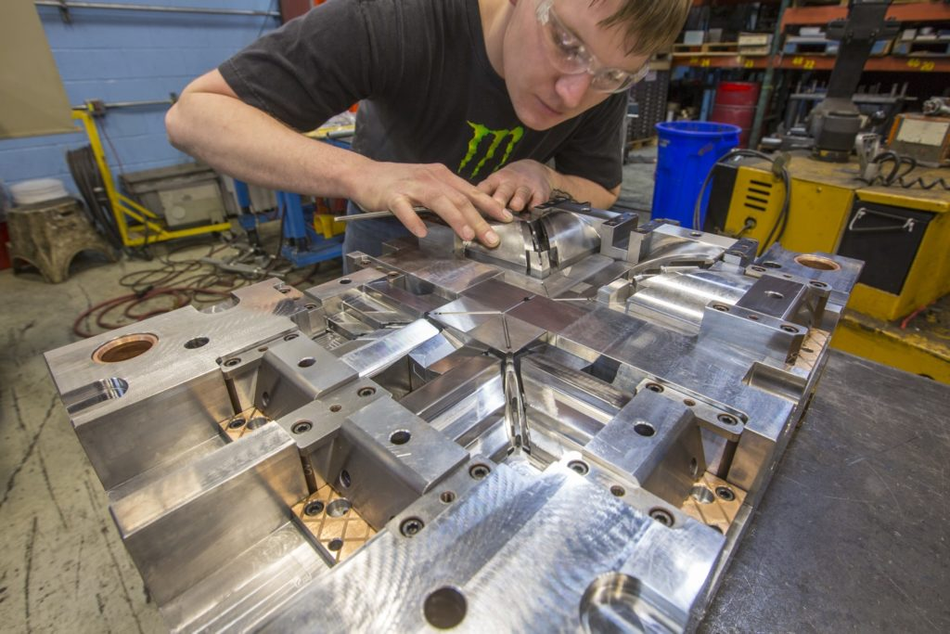

Appropriate prototyping is key in the early stage of product development, as well as prior to production, for the quality of the final product[3]. Proper investment early on can lead to higher quality and cost savings in the long run. Quality prototypes from day one can establish customer faith and allow for user input, securing sales after production. However, prototype manufacturing costs can be high because of the extremely low volume, required manufacturing setup, and material choice. For example, although volume-limited, aluminum molds are effective for the fine-tuning of injection molded components[4]. Once the design is optimized, the expensive production-ready mold with a material capable of high volume can be purchased.

Taking advantage of cloud manufacturing can help achieve quality parts in all stages of development, maintaining customer interest, reducing design costs, and meeting market demands.

Quality is essential throughout the development process.

How can cloud manufacturing help?

Cloud manufacturing opens up access to a quality management service. Partnerships are maintained between the cloud service and each supplier, such that parts are made to spec, thereby achieving a high degree of quality assurance. An advantage of cloud manufacturing for a small company needing low-production volume is that orders can be bundled with those from other startups and sent to top-notch manufacturers, which prioritize larger orders. This approach not only lowers the price but also improves quality, thanks to better customer service and access to expertise. With cloud manufacturing services, startups can obtain the same quality service as larger established players, from the very start of their development process.

3. Skilled Labor

The manufacturing industry as a whole is struggling to recruit and maintain skilled laborers. Startups may feel this reality even more acutely, as large companies often have more resources to attract the best candidates. The skills gap across the industry also means that startups may have to work with temporary or freelance talent, which can further complicate operations.

While crowdfunding is providing entrepreneurs a way to access up-front cash[5], most hardware startups are initially low on capital. Compared to software, success in hardware production requires more experts from various fields, including engineering, business, quality, and supply chain. While team members can cover multiple roles, a lack of specific talent will no doubt exist, and these gaps are often unknown until way down the road. Hiring additional people for these jobs is ideal, but qualified candidates need to be willing to take the risk. A startup may be only able to offer equity along with the promise of a future full-time salary[6]. Capitalizing on established expertise through a cloud service can alleviate this skill shortage.

Quality is essential throughout the development process.

How can cloud manufacturing help?

Quality is essential throughout the development process.

Success with a lean team is possible with cloud manufacturing. Since procurement needs are mostly digitized, less staff is required to operate effectively. The investment in other skilled labor has already been made by the cloud manufacturer and its network of top suppliers. Engineers from the hardware startup can optimize their designs in real-time during the production process with access to the cloud solution.

4. System Know-how

Hardware startups usually have a high IQ in terms of product development and innovation. However, when setting up systems to deliver their products on time, they often stumble. Most budding companies lack experience in setting up high-volume manufacturing operations. The journey from the initial vision to the final product is a challenge for anyone, and startups may require additional time or a more experienced partner to show them the ropes.

Regardless of a product’s excellence, actual success still requires a sufficient overall system that can ensure promises to customers are honored. Tesla is a classic example of this, despite being one of the most famous electric vehicle companies in the world, they faced massive challenges when attempting to deliver the low-cost model 3 after facing manufacturing volume challenges[7]. An established system that can anticipate problems rather than problem-solve them on the fly will lead to a successful journey to the final product.

Precision engineering doesn't always lead to customer satisfaction. Image source: Tesla.

Precision engineering doesn't always lead to customer satisfaction. Image source: Tesla.

How can cloud manufacturing help?¶

Cloud manufacturing can be utilized from the initial planning stages of a manufacturing project. In addition to establishing supply capacity, manufacturing networks can be used early on to identify any problematic features within initial component drawings. Additionally, suppliers can offer alternative material choices that are more cost-effective or meet other market requirements. Assessing any issues at the beginning stages helps prevent significant slips of the schedule and budget, allowing for a smooth scale-up.

5. Scaling

The discussion of system knowledge introduces the need for scaling methodology. To find success, a startup must evolve to a position where it can foster and support the growth of its business. This means having the ability to grow without significant impediments, gain a larger market share, and introduce new products without major disruptions in business operations. Scaling is the ultimate challenge for any startup and can only be attained after successfully tackling all previously stated challenges.

How can cloud manufacturing help?

To achieve growth at scale, a startup needs the right staff, systems, technology, supply chain, and partners. Cloud manufacturing can be a one-stop solution to help hardware startups address these factors. Resources are available to build a quality supply chain, access highly skilled labor, and manage procurement. A startup can request real-time input from a team of experts during the component design phase. Scaling a small company while continuously improving the product is possible without disturbing the existing business processes.

KREATIZE understands startup specific challenges

Hardware startups have distinct challenges they must face on their journey to maturity. As a startup itself, KREATIZE was created to transform the outdated and inefficient procurement processes of both small and large hardware businesses. We are also deeply familiar with some of the challenges faced by startups in this space. In fact, one of our main goals is to provide fellow startups with solutions to their specific problems as nascent businesses that require top-notch manufacturing services.

KREATIZE offers startups access to a network of manufacturers for a variety of materials and processes for their low-volume needs. Our team of experts can guide the hardware development process and liaise with suppliers to achieve product quality, on-time delivery, and successful business scale-up. With our services, hardware startups can focus on innovation while still maintaining control of the product release through the cloud.

References

Statt, N. For hardware startups, it’s getting less hard [Internet]. 2015 Apr 11 [cited 2021 Jul 11] Available from: https://www.cnet.com/news/for-hardware-startups-its-getting-less-hard/

https://www.vox.com/2015/7/13/11614656/i-waited-19-months-for-the-magic-coin-card-and-it-was-a-big

https://rapidsrepro.com/advantages-disadvantages-prototyping/

https://www.cnet.com/roadshow/news/tesla-model-3-model-y-orders-delay/

This article was written with contribution and editing from engineer and technical writer Kimberly Sweetland.