Glass vs. carbon fiber composites

Which 3D printing material should you choose?

Both glass and carbon fiber composites extend the versatility of fused filament fabrication (FFF) 3D printing by enhancing a part's mechanical properties.

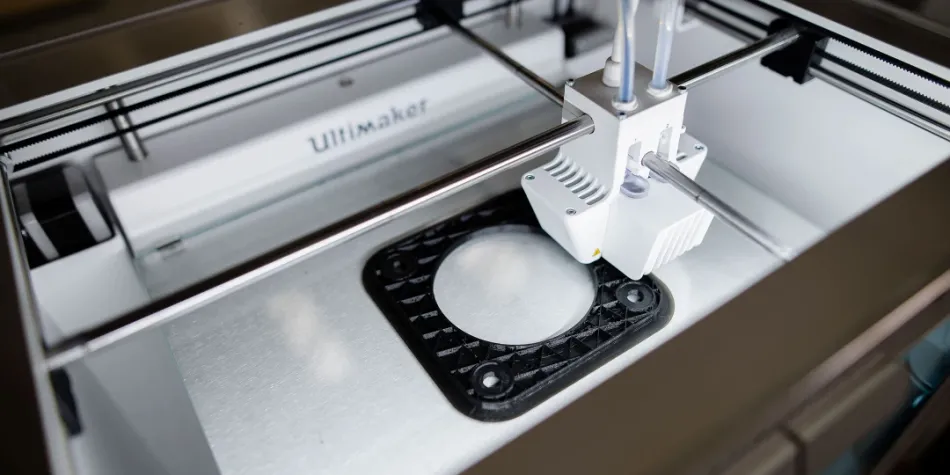

For example, by using glass or carbon fiber composite materials on a compatible 3D printer (like the Ultimaker S5 Pro Bundle or Ultimaker S3), you can quickly and affordably produce high-strength parts that:

Validate geometries

Optimize designs

Reduce weight

Consolidate assemblies

Test prototypes that will be injection molded

Replace metal components

But which composite 3D printing materials should you choose in the first place?

After all, both glass and carbon fiber filaments can end up having similar mechanical properties in a 3D printed part.

This is especially true when leading materials companies (like those whose print settings profiles are downloadable via the Ultimaker Cura Marketplace) can boost various properties by tweaking:

Base polymer choice (e.g. ABS, nylon, polycarbonate)

Base polymer mix (e.g. ABS + polycarbonate)

Fiber length (e.g. long or chopped, short or milled)

Fiber fill percentage (e.g. 20% glass fiber)

And many more variables...

So why would you choose one fiber over the other?

Glass vs. carbon fiber composites – which is the winner?

Roger Sijlbing, Head of Sales at BASF 3D Print Solutions Additive Extrusion Systems, told us:

There are a lot of considerations to determine which material fits the application. Even within for example automotive, both [glass and carbon fiber composite] materials could fit. It depends on the requirements of the application and the total cost of ownership.

So, to guide your material choice based on the requirements of your 3D printing applications here's an at-a-glance list to show which composite (generally) wins for different 3D printing requirements:

| Requirement | Winner? |

|---|---|

| More affordable | Glass fiber |

| Tensile strength | Carbon fiber |

| Stiffness | Carbon fiber |

| Durability | Glass fiber |

| Flexibility | Glass fiber |

| Low weight | Carbon fiber |

| Heat resistant | Both |

| Chemical resistant | Both |

| Fatigue resistant | Carbon fiber |

| UV-light resistant | Both |

| ESD safe potential | Carbon fiber |

| Electrical conductivity potential | Carbon fiber |

| Allows radio wave passthrough | Glass fiber |

| Multiple colors available | Glass fiber |

That might be useful if any of those properties are a priority for your application.

But what if there’s still no clear choice between glass and carbon fiber for your 3D printing needs? Then, there are a few more considerations to inform your choice.

To understand these, let’s dig deeper into the manufacturing processes involved...

How glass and carbon fibers are made

Glass fiber

Glass fibers began to be commercially produced in 1936. In fact, the material's invention led to the partnership known today as Owens Corning.

Glass fibers are made by melting silica to remove impurities. The liquid glass is then extruded through a heated metal plate with small holes – called a bushing. While the glass strings are cooled from around 1,200 °C with water and air, they are stretched into thin fibers as they are pulled onto a winder.

Carbon fiber

Carbon fiber’s manufacturing process takes place at a molecular level. Despite the material's higher price tag, its rigidity and excellent strength-to-weight ratio have made carbon fiber the composite additive of choice for lightweight automotive and aerospace applications.

Starting life as a liquid polyacrylonitrile precursor, the fibrous mix of carbon atoms is then oxidized at around 300 °C to stop fibers from melting together. Then it is carbonized in an oxygen-free oven at temperatures of up to 1,000 °C. This process causes atoms to fuse and then expel any impurities, resulting in pure carbon atoms in very rigid strings.

Afterwards, carbon fiber strings pass through a surface treatment bath to etch the surface of the carbon. This makes the carbon strings more resilient and better able to stick to coating chemicals.

Coating, chopping, or milling fibers for use with 3D printing filament

Technically known as 'sizing', coating chemicals (like polyurethane, epoxy, or glycerin) allow the inert glass or carbon fibers to more easily interface with the polymer it will be mixed with. By matching the chemistry of that polymer, the coating strengthens the adhesive bond.

Fibers are usually coated when they will be cut or 'chopped' into lengths of up to 7 mm. The result is a composite 3D printing material that is reinforced by ‘long fibers’ that weave together within the polymer matrix.

But not all carbon and glass fiber used in 3D printing filament is coated.

While not coating or using a lower-quality coating might be a reason a composite material is less expensive, it can also be a legitimate choice.

That's especially true if the fibers will be milled into a fine powder, also known as 'short fibers'. Between 30 to 150 microns in length, these fibers have a large surface area making coating less necessary. In this case, the composite filament would more accurately be described as 'filled' (rather than 'reinforced') with carbon or glass fiber.

This approach of not coating milled fibers is not necessarily a bad thing. It just results in different material properties. Instead of being stiffer and stronger, the composite material will likely be more durable and impact-resistant.

After coating, chopping, or milling, the fibers are mixed with the base polymer(s) to create a composite material that can then be extruded into 3D printer filament.

This final filament extrusion is important because it's here that the long glass or carbon fibers become orientated within the polymer matrix. Running along the length of the filament, they create a weaving effect that provides extra strength for a 3D printed part. (This orientation is the reason why FFF 3D printers can extrude filament with up to 7 mm long fibers, through a 0.4 or 0.6 mm nozzle.)

How to choose between different composite materials

With so many things in life, you get what you pay for. And composite 3D printing materials are no different

Composite materials from smaller filament companies may be more affordable. But because they don't necessarily specialize in the material science used to develop the composite, these companies might buy ready-made pellets from a larger wholesaler. They then extrude the filament themselves, on machines that may not have the torque required to properly orientate the fibers within the polymer matrix, resulting in a lower-quality filament.

By contrast, leading manufacturers have decades of expertise in developing reinforced polymers – often for the injection molding industry. By applying that expertise to additive manufacturing, using the highest-quality fibers, coatings, and processes, they fine-tune their polymer matrixes and extrude them on industrial-grade machines. This results in a filament that more readily carries the mechanical properties you need over to your 3D printed part.

For example, composite filaments from Clariant include:

PA6/66-CF20

PA6/66-GF20

PA6/66-GF20 Flame Retardant using Exolit®

PC+ABS-GF15

PLA-HI-GF10

BASF's composite filaments include:

PAHT CF15

PET CF15

PP GF30

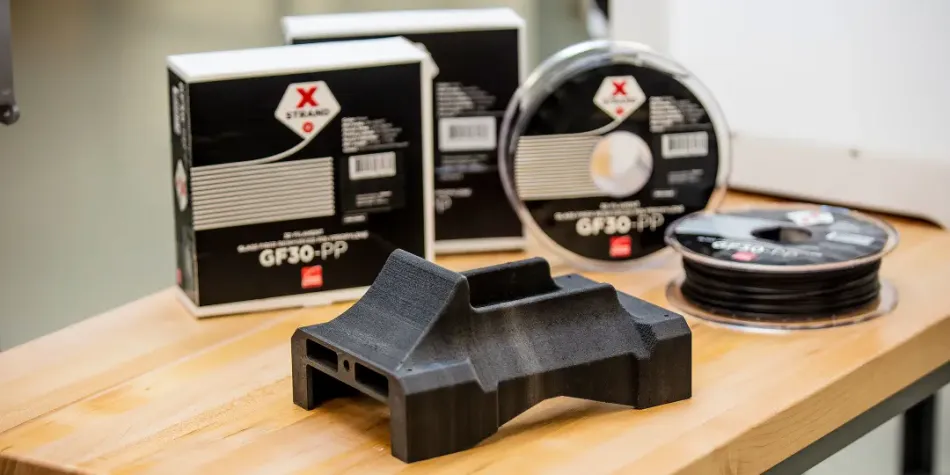

And Owens Corning's:

XSTRAND® GF30-PA6

XSTRAND® GF30-PP

Conclusion: Make an informed choice

All these composite filaments (and many more) are listed in the Ultimaker Cura Marketplace.

By downloading their predefined print profiles, you gain a plug-and-play 3D printing experience with the Ultimaker S5 Pro Bundle and Ultimaker S3 – without the need for trial-and-error. Plus, the materials’ descriptions and datasheet links make it easier to choose the right composite material for your application.

This means you can be more confident to achieve the mechanical properties and high-quality results you need – even with your first print.

And with a deeper understanding of how carbon or glass fibers are used to reinforce 3D printing filament, you can leverage the many benefits of composite materials for your own in-house production needs.