Hourly model manufacturing succeeds the request for quote process

Cloud manufacturing offers a sustainable and accessible model for innovators of all sizes.

Image: BMW

The hourly manufacturing model replaces the traditional request for quote model, giving businesses more resources to focus on their product. Instead of requesting a quote and negotiating every time you need manufacturing services, the hourly model provides a transparent hourly cost. This new paradigm in manufacturing services is part of the shift towards cloud manufacturing that uses data-driven decisions and resource management to radically improve the delivery of parts and components.

Introduction to cloud manufacturing

Cloud manufacturing, also referred to as CMfg or CM, transforms manufacturing resources and capabilities into manufacturing services based on a cloud platform. As manufacturing becomes more complex and integrated, cloud manufacturing offers a more sustainable and robust supply chain based on intelligent decision making and accurate resource management.

The hourly model of manufacturing

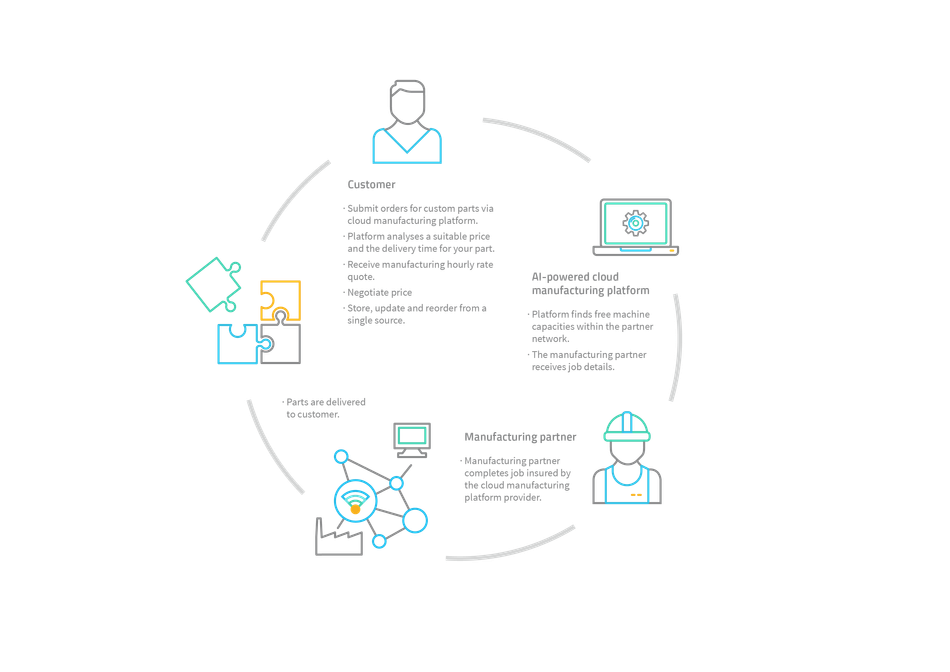

The hourly model for manufacturing services provides enormous benefits to both customers and manufacturing service providers. It works like this; you place your order for manufacturing services via an online platform. The cloud-based platform uses AI-based software to analyze your request and find the best manufacturing solution for you. The hourly rate for the services you require is then negotiated based on expected future demand, process type, and complexity. The initial order is completed by manufacturers from a network of manufacturing service providers around the world and delivered to you. Future orders using the same manufacturing process are submitted via the same platform at the same negotiated price. The never-ending request-for-quote cycle is dead.

Towards automation

The hourly model moves your procurement process closer to being fully automated, or at least to a level that removes the effort of constant negotiation, fact-checking, and discussion associated with traditional procurement processes. Once the hourly rate is negotiated, future orders are quickly placed, enabling shorter process time, lower transaction costs, and faster delivery times. This process is sped up by storing and managing technical drawings and CAD files in the same platform where the parts are ordered. This enables multiple manufacturers to access the same product files without emailing or updating.

Robust Financial planning

Understanding manufacturing as hourly costs rather than whole job pricing provides financial stability to engage in innovation. The exact price of testing new materials or services can be understood and planned into future budgets.

At a higher level, cloud manufacturing offers manufacturing without investment. Often when a company reaches a certain size, they will invest in their own manufacturing facilities to bring their procurement and service under control. Cloud manufacturing supports scalability through the arbitrage effect from a large network, utilization of individual capacity, and using global resources. This enables even large businesses to enjoy the safety of streamlined manufacturing without the massive investment.

Total transparency

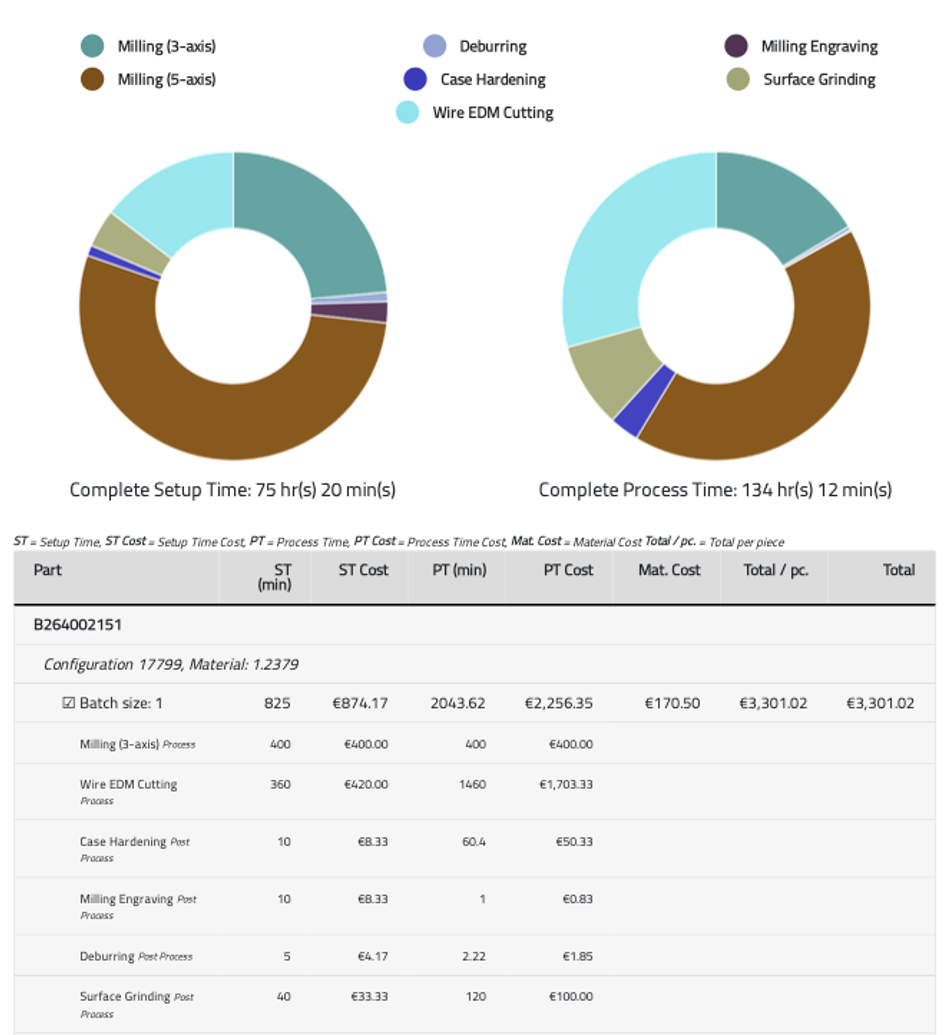

The cloud manufacturing platform analyzes and calculates process times for manufacturing services and shares this information with you so that the cost of production is absolutely transparent; this also reveals the true cost of complex projects. Figure 1 shows the overall setup and process time of a project with diverse custom parts.

Drives innovation and sustainability

Price transparency and low resource procurement mean design and development companies of any size can test ideas, knowing exactly how much it costs and how long it takes. The most significant benefit of cloud manufacturing is highly detailed resource management. The different physical and virtual resources on offer from suppliers can be dynamically assigned and reassigned according to user demand—no gaps in production, no additional fees added to compensate for slower periods, etc. Manufacturers can extract jobs from the pool of demand, while customers' needs are distributed throughout a network instead of being placed in a line.

This opens the possibility of innovation to both customers and providers. When resource management is done with a view to abundance, not scarcity, it provides the stability and space to explore innovation, whether that is new process models or creating new material prototypes.

Who is it for?

Cloud manufacturing benefits companies on both sides of the manufacturing coin. For customers ordering parts the financial safety, saved procurement resources and financial stability translates directly into faster time to market clearer. For manufacturers, the model offers a more efficient and more data-driven method of managing their technical and administrative resources for manufacturers. The hourly model has been shown to be 31% less administrative work and provide a 17% savings on the total cost of procurement.

The hourly rate model with cloud manufacturing is suitable for traditional fabrication processes such as turning, milling, waterjet cutting, laser cutting, and additive manufacturing processes, including filament fabrication, multi-jet modeling, selective laser sintering, and selective laser melting.

The problem it solves

Request-For-Quote (RFQ) is slow, expensive, and requires resources from both manufacturing and customer sides to manage. The process is wasteful and bears unnecessary high transaction risk. The traditional RFQ process favors larger manufacturing companies as it requires intense resources to manage the individual negotiation of multiple jobs. This process has been fairly murky for some time. Customers are forced to accept quotes that are deemed reasonable, while manufacturers need to balance not knowing if they can retain customer loyalty. The hourly rate reduces both things by providing a clearer per hour cost for manufacturing that is based on the amount of commitment given by the customer. This model pushes for transparency from both sides.

Why now?

Manufacturers of custom parts and OEMs are under enormous pressure – because their manufacturing and production processes are often designed for constant demand, long lead times, and high volumes. Current trends, however, go in the opposite direction: technology is developing rapidly and the average life cycle of innovative products is getting shorter and shorter. At the same time, the demand for tailor-made products is increasing. This means: smaller batch sizes, shorter lead times, and product development cycles at lower costs are in demand. And all this in an environmentally friendly and sustainable way. The hourly model supports the mechanical engineering industry on this path of transformation and makes it more competitive, more transparent, and more innovative as well as making the supply chain more resilient. This approach creates a truly collaborative approach to product development and manufacturing.

Enabling agile design

The hourly model enables an agile approach to manufacturing that can determine the future of innovation-focused companies. Imagine a European furniture company with 1900 employees and a € 380 million turnover that manufactures various mechanical products for furniture. This company can use fixed machine hourly rates for their main processes such as 5-axis milling that allow it to precisely know its manufacturing costs. This enables the company to confidently invest in new product development either using new processes such as additive manufacturing or new materials such as carbon fiber without investment into the manufacturing process itself or building and qualifying a new network of suppliers.

Is this for you?

Kreatize is the first company to have developed the hourly model for cloud manufacturing onto their platform. From their digital platform, customers and manufacturing partners can easily handle the complete process from ordering to delivery of their custom parts. Customers can order a part directly online with just a few clicks or request a quote and have full transparency of their order at all times.

Conclusion

Cloud manufacturing with the hourly model is killing the inefficient request for the quote process. With a focus on transparent pricing and data-driven resource management cloud manufacturing and the hourly model of manufacturing services are contributing to a manufacturing future that is automated, innovative, and sustainable.