How 3D printing is enabling faster design, higher productivity, and more customization in manufacturing

Introducing the first article in a new series, making clear the impact of additive manufacturing on Manufacturing, Transport, Packaging, and STEAM. In this article, we're zooming in on Manufacturing.

Transforming Production: The Unseen Power of 3D Printing

With the playbook “Transforming Production - The Unseen Power of 3D Printing”, manufacturers and engineers can draw inspiration from experts who are already using 3D printing in their production processes. This free PDF provides high-value application suggestions and detailed case studies of what you can achieve using FDM (Fused Deposition Modeling) 3D printing technology.

While many people don’t tend to think about how the products they use are made, the world of manufacturing—responsible for the transformation of raw materials into goods—is behind virtually every object or system we use, from toothbrushes to cars.

With newer manufacturing processes like 3D printing (also known as additive manufacturing) becoming more common, there have understandably been questions about how they will change and disrupt the manufacturing industry. Today, it’s clear that while 3D printing may not exactly replace existing manufacturing processes, it is finding its role amongst them, both to make manufacturing more efficient and to fill production gaps for small-batch and custom parts.

This article is the second in an UltiMaker-supported series about the wide-reaching impacts of additive manufacturing in Manufacturing, Transportation, Packaging & Automation, and STEAM. In it, we’re focusing specifically on the vertical of industrial manufacturing to understand how 3D printing technologies are not only fitting into existing production workflows but how they are helping to transform production chains and, more broadly, how parts are made.

Benefits of 3D printing for manufacturing applications

Manufacturers are becoming increasingly interested in leveraging additive manufacturing technologies in order to reap its benefits. But what exactly are the advantages of using 3D printing in a manufacturing context? Let’s take a look.

Faster lead times

Arguably the biggest benefit of adopting 3D printing for manufacturing (and beyond) is that it enables faster lead times. In the context of manufacturing, 3D printing can be used as early as the prototyping stage to accelerate product development. Before 3D printing, prototyping could take weeks if not months due to the long turnaround times for molds and tooling. Now, product developers can easily print one-off prototypes in-house, evaluate them, and then implement changes in CAD software until the design is validated. Faster lead times also extend to other manufacturing applications, like tooling and spare parts. In these cases, the ability to rapidly print manufacturing parts can improve production yields and minimize machine down times.

Agile production

In addition to faster lead times, 3D printing has the benefit of being one of the most agile production technologies. The nature of the technology, which can directly produce a wide variety of parts without the need for tooling or molds, means that manufacturers can create parts on the fly. Unlike injection molding, which requires a specific manufacturing setup as well as large production volumes to be economically viable, 3D printing can be used to make parts in small volumes on-demand. This capability also reduces the need for inventories and storage (and their associated costs).

Customization

In line with the agility 3D printing unlocks, the technology is also uniquely suited to producing customized products and parts. By simply tweaking 3D models or designing one-off parts from scratch (using reverse engineering, for example), 3D printers can create personalized or one-of-a-kind parts in a cost-efficient way. This capability empowers manufacturers within their own operations to make unique machine parts or fixtures, as well as to diversify their production capability to include mass customization.

Design freedom

Design freedom has been one of the biggest selling points for 3D printing and for good reason. The technology is able to create previously impossible geometries, including complex organic shapes and internal lattices. This benefit itself has many knock-on advantages, including the creation of higher performance parts, part consolidation (which minimizes assembly times), and greater material efficiency. In other words, parts can be designed to meet performance requirements, while minimizing the amount of material used. This can translate to lower material costs for manufacturers.

Distributed manufacturing

The concept of distributed manufacturing is becoming increasingly popular in the manufacturing world in order to reduce supply chain risks. In short, it entails diversifying where products are made, often with an eye on localized production. With 3D printing, organizations can achieve more efficient, local production by simply sending design files to manufacturers in different locations. This approach not only has supply chain benefits (making it possible to switch manufacturers when others cannot fulfill production), but also potential environmental benefits, since it minimizes the need for product transportation.

Ways 3D printing is used in manufacturing workflows

Now that we’ve seen the many benefits additive manufacturing can offer in an industrial manufacturing context, we want to highlight some of the specific ways the technology is currently being used in the vertical.

Rapid prototyping

Today, 3D printing is one of the leading approaches for rapid prototyping. In fact, this application is still among the most common for AM adopters, with 72% of manufacturers using the technology to create prototypes. Not only is AM equipped to deliver prototypes quickly, if changes are needed, whether it’s a full design overhaul or a small adjustment, users can make the changes digitally and reprint for further validation. Not only does this approach speed up product development (and thus reduce overall production lead times), it can also improve overall product design, since multiple iterations can be done without significant added time or cost.

Tooling & Fixtures

Tooling, a market valued at over $73.60 billion, is an essential part of traditional manufacturing and more and more manufacturers are turning to 3D printing technologies to create mold inserts, assembly aids, and jigs in order to streamline their production workflows.[1] This application area is actually one of the fastest growing: whereas only 37% of manufacturers reported using AM for tooling in 2019, that number grew to 57% in 2021.[2]

Compared to traditional production methods, 3D printing enables these essential manufacturing parts to be made rapidly and on-demand. For example, injection molding company Rosti Group has successfully implemented the UltiMaker S5 Pro Bundle to produce assembly fixtures rapidly and cost efficiently. Compared to more traditional CNC machining, the company has reduced lead times from a week to just seven hours and cut costs from $450 per part to just $15, all without compromising quality or strength.[3]

Moreover, 3D printed custom jigs and assembly fixtures not only improve production efficiency but also enhance ergonomics and factory-floor safety for operators. Industrial service provider ERIKS uses UltiMaker’s 3D printing solution extensively to improve onsite safety. For example, the Dutch company regularly uses a 3D printed tool that makes it possible to replace a large roll of wrapping film safely by a single person.[4] Thanks to this tool and others, the company says it has saved €350,000 at its production facilities by eliminating safety hazards and upping its production.

Spare parts

An important part of any manufacturer’s job is to ensure that every machine and system in its production line is running smoothly. In some cases, if even a single machine goes down, production runs can be significantly delayed. 3D printing can help overcome this challenge by creating the spare parts needed to minimize machine downtimes. German 3D printing service 3D Point uses a fleet of UltiMaker S Series 3D printers to deliver replacement parts to many different clients. These printed components are printed in series (typically 300 to 5,000 pieces per order) and help clients in various industries, from transport to consumer products, keep their own production and operations running smoothly.

With 3D printing in house, manufacturers can build digital inventories and quickly print temporary replacement parts for machines to keep them operational while waiting for the “official” part to arrive. In some cases—and thanks to the rise in engineering-grade materials, such as carbon fiber composites—end-use spare parts can also be printed directly. In cases of legacy systems, it is possible to reverse engineer obsolete parts, extending the life of machines that would otherwise become unusable. The use of AM for repair and maintenance applications has grown over 30% from 2017 to 2021.[2]

Final products

Of course, 3D printing is not only used to support traditional manufacturing workflows, it can also be used as a production technology in its own right. Today, a variety of manufacturers across different industries are utilizing additive technologies to produce final parts and products. This application area has grown in part thanks to more material diversity, ranging from high-temperature thermoplastics, to composite filaments, to stainless steel.

It’s worth mentioning that the technology isn’t so much competing with mass production processes like injection molding. Instead, it is helping to fill production capability gaps, particularly for customized products, low-volume production runs, and sophisticated parts with complex geometries that would be impossible to produce using other processes.

Opportunities for future innovation

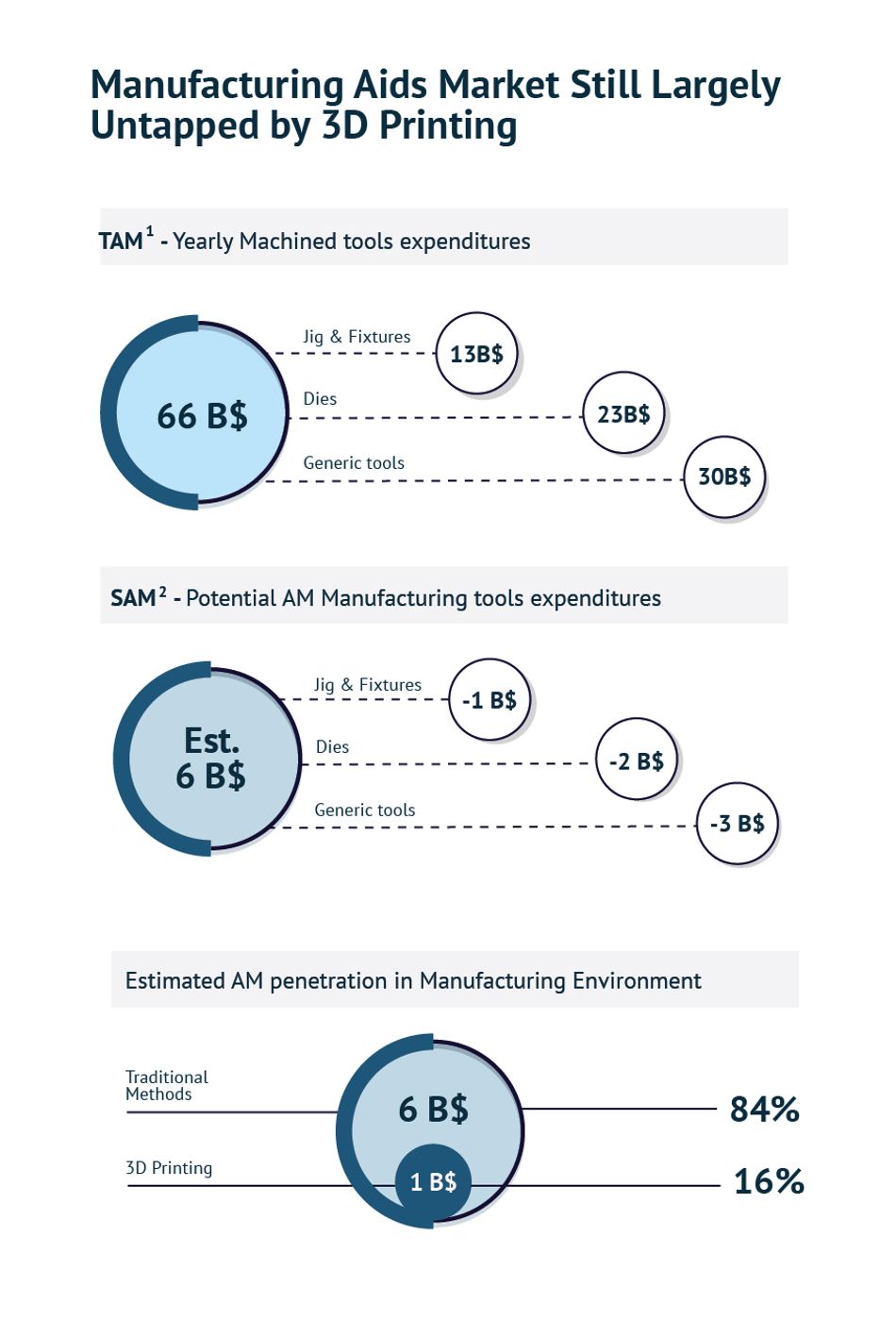

Despite the notable growth in adoption of additive manufacturing for industrial manufacturing applications, there are still untapped opportunities. Looking at manufacturing aids specifically, traditional manufacturing processes still retain the dominant share of the market value (at 84%), while 3D printing is making inroads at 16% (worth $1 billion).

Continued adoption will be driven by greater awareness of AM’s existing capabilities as well as new opportunities unlocked by hardware, software, and materials advancements. On a technological level, as printing hardware and software become increasingly sophisticated and automated, 3D printing will become more and more cost and time efficient, leading to broader adoption in the manufacturing sphere. We can look at large-format additive manufacturing (LFAM) as an example of this: as this technology progresses, there will be opportunities for larger manufacturing components, like molds for the automotive and construction industries.[5]

Once a bottleneck for AM adoption, material availability is ever growing. Engineering-grade thermoplastics as well as heavy duty composite materials already have the potential to replace more costly metal parts for end-use applications, which can further improve the efficiency of production lines. For example, the UltiMaker Method Series—comprising neat polymers and heavy duty composites—are built for manufacturing applications and are already creating value for industrial manufacturers.

Finally, 3D printing has the potential to strengthen global supply chains by creating a more agile production chain through distributed manufacturing, digital inventories, on-demand printing, and better material efficiency. Overall, it gives manufacturers greater autonomy, which can actually shorten supply chains and improve resilience.

Up next…

The impacts of 3D printing on industrial manufacturing can’t be denied: the technology offers significant benefits and has various transformative applications, from prototyping, to tooling, to final end-use parts. In the next installment in this series, we’ll be shifting gears to look at the transportation industry, exploring how additive processes are advancing the production of cars, planes, trains, and more.

References

[1] Dies, Jigs and Other Tools Market- Industry Analysis and Forecast (2022-2029) [Internet]. Maximize Market Research. January 2023. Available from: https://www.maximizemarketresearch.com/market-report/global-dies-jigs-and-other-tools-market/93511/

[2] The Future of 3D Printing: Five Predictions [Internet]. Jabil. 2021. Available from: https://www.jabil.com/blog/future-of-3d-printing-additive-manufacturing-looks-bright.html

[3] Rosti: From concept to reality with UltiMaker. [Internet]. UltiMaker. 2023. Available from: https://ultimaker.com/learn/rosti-from-concept-to-reality-with-ultimaker/

[4] ERIKS: Working clean, certified, and in control with 3D printing [Internet]. UltiMaker. 2023. Available from:

https://ultimaker.com/learn/eriks-working-clean-certified-and-in-control-with-3d-printing/

[5] A New Approach to 3D Printing a Yacht Hull Mold [Internet]. Thermwood. Available from: https://blog.thermwood.com/en-us/a-new-approach-to-3d-printing-a-yacht-hull-mold