How Heineken Improved Production Line and Reduced Costs with 3D Printing

Heineken has been using 3D printing to improve production efficiency, employee safety, and maintenance processes.

Introducing a case study from our latest series making clear the impact of additive manufacturing on Manufacturing, Transport, Packaging, and STEAM.

Heineken’s relevance worldwide

Heineken has a proud history as a family-owned, independent brewer dating back 150 years. With over 300 brands sold in over 190 countries and employing over 85,000 people, Heineken has a larger global presence than any other brewer.

Innovation is vital in the company's strategy for securing a sustainable future. Heineken embraces change and has a track record of innovation, starting with the invention of A-Yeast in 1886. Today, innovation is embedded throughout the company, with local innovators turning local needs into opportunities while successful ideas are scaled globally.

Manufacturing challenges

As a leading company, Heineken is constantly trying to optimise its processes regarding production and quality. These objectives involve optimising production lines, finding cost-effective solutions to improve machines, and reducing costs and delivery times while ensuring employees' safety. However, equipment malfunction can constantly challenge production and machine changes are usually costly and slow due to the production process.

Unplanned machine downtime can affect production severally. Specialised machines with tailored designs frequently have limited replacement parts supply. Therefore, any equipment breakage may result in a long replacement time, compromising the overall equipment effectiveness.

A similar problem arises when dealing with the maintenance of outdated assets. In this case, the company may face the situation of discontinued or hard-to-find parts, leading to expensive outsourcing or importing and extended machine downtime.

Heineken has adopted 3D printing in its factories to speed up and enhance the maintenance process. The printed pieces have replaced traditional machine parts and have even led to the development of specialized tools.

How Heineken has been using 3D printing

The company started using 3D printing in the Seville plant. First, the Seville plant set up a 3D printing lab to improve the manufacturing process regarding output, uptime, and safety. The Heineken team quickly realised that 3D printing gives them the flexibility and speed they need while still being affordable and easy to implement. In the first stages of implementation, using 3D printing resulted in a 70 - 90% cost reduction in the application and a decrease in delivery time of 70 - 90%.

Improving employee safety

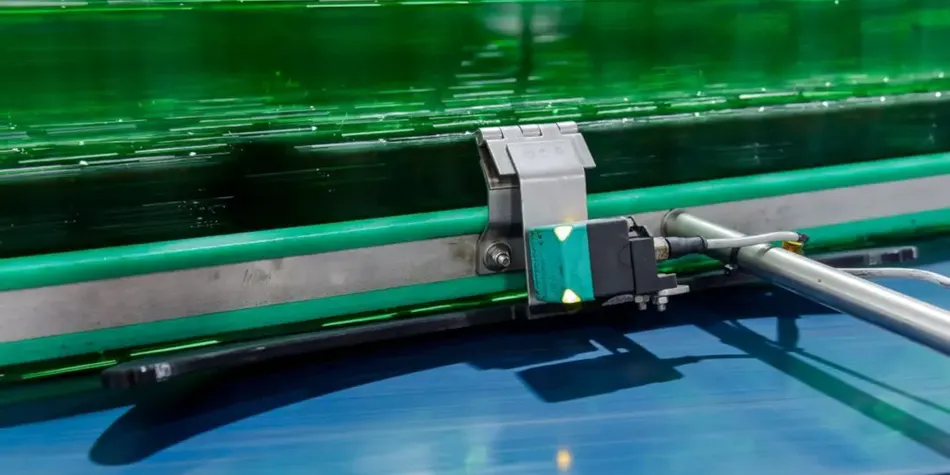

At Heineken, employee safety is a top priority. The company has developed advanced safety latches to improve safety during machine maintenance. These latches have been installed in almost all machines at the brewery and automatically lock when the machines are stopped. This prevents accidental activation during maintenance work.

To enhance the visibility of the latches, they are 3D printed in bright red. This serves its purpose effectively and generates awareness and appreciation of the potential of 3D printing among employees. They can witness the practical benefits of this innovative technology in their workplace.

Streamlining manufacturing processes with 3D printed parts

The next step in the application of the 3D printing solution by Heineken was to print spare parts that had proven difficult to replace. The team immediately identified that 3D printing outsourcing discontinued parts saved time and money. In addition, they could print plastic parts which could function as structural replacements for metal parts. The 3D printing process removed the constraints associated with traditional manufacturing and eliminated the need for stock.

Optimizing part designs

The advantages of 3D printing include easy iteration of designs and cost-effective production times, making it possible to create alternative designs and test parts on-site. Plastic parts are lightweight yet strong when designed and made with the right materials. In addition, it is easy to redesign and optimize parts without the constraints of outsourcing.

At the Seville brewery, the team implemented these advantages by replacing several modified components with 3D-printed ones. The metal part of the former conveyor belt bottle guide often caused blockages or ejected good bottles on the ground by knocking over bottles. The new 3D-printed parts solved this problem, saving time, money, and resources.

3D printing tools for maintenance

Heineken has leveraged 3D printing technology to create several tools that streamline and speed up maintenance processes. These tools were printed from Tough PLA, which is easy to print and provides comparable strength and flexibility to ABS.

One example of a developed tool is the stopper tool, which is used to loosen and tighten the columns of guiding wheels that apply bottle labels. Previously, this tool had to be custom-made using CNC machining. Thanks to advancements in 3D printing technology, production costs have been reduced by 70%, and delivery time has been shortened from three days to just one day. . Even a seemingly simple tool like the toroidal rubber cutter can be printed in less than an hour, contrasting the average 10-day delivery time when outsourced.

Materials selection

In order to ensure the long-lasting durability of 3D printed parts used in their production process, Heineken carefully selected materials that can withstand high stress, temperatures, moisture, and impacts. They use Tough PLA, Nylon, and TPU 95A, which have excellent mechanical properties suitable for different applications. Tough PLA is ideal for pushers and tools, while Nylon is used for parts that need to function with metal parts. The flexibility of TPU 95A is perfect for bumpers and protective parts. By choosing the right materials, Heineken ensured that their 3D-printed parts would be up to the challenge of the manufacturing line.

3D printing results

Heineken has declared the Seville pilot project a success after a year of using the UltiMaker S5 printers. They reported increased employee safety, lead time reduction, and cost savings on all processes using printed parts.

By 3D printing functional end-use parts on demand, the company was able to optimize functionality and ensure availability. Furthermore, custom tools have made maintenance and production changeovers considerably easier and faster for employees. On average, the delivery time of required parts is 80% faster than external sourcing, while costs are 80% lower than historically sourced parts. The company sees 3D printing as a technology that provides value and helps increase work efficiency.

Leading 3D Printing with UtiliMaker

UltiMaker is a leading company specialized in manufacturing reliable and user-friendly 3D printers. These printers are designed and tested to run 24/7, ensuring that you achieve the results you need quickly and easily. UltiMaker's software, Cura, is the world’s most popular 3D printing software and is trusted by millions of users. It is integrated with CAD software and has a wide library of plugins to customise the print preparation experience.

To scale your production, Ultimaker provides the Digital Factory. Ultimaker Digital Factory is a cloud-based set of tools that enables users to connect their Ultimaker 3D printers to upgrade their printing experience effortlessly. It allows for remote print job queuing and unlimited job history. With in-cloud maintenance scheduling, users can keep informed of upcoming tasks and manage future tasks.

UltiMaker also offers the widest range of materials on the market through its Material Alliance, from advanced polymers to carbon fibre composites, allowing you to choose the perfect filament for your application. Moreover, UltiMaker's global network of service partners provides professional installation, training, and maintenance services in your language and time zone, ensuring that you receive dedicated support wherever you are.