How to Avoiding Quality Problems in CNC Machining Industry

Quality is a keyword related to production results in all sectors of the manufacturing industry, especially the results of CNC machining.

Quality Assurance

This is a subject that is often discussed in the context of manufacturing technology 4.0 and it is a problem of quality. How a mechanical and industrial design automation designer can choose the process specifications that will ensure that they get the exact quality and output and precision they want for their custom machining and mass products. Lots of tools and methods are used on CNC machines to produce a precision product.

Mastering the three Quality 4.0 technologies in manufacturing

Quality is a keyword related to production results in all sectors of the manufacturing industry, especially the results of CNC machining. To meet customer specifications and avoid quality problems when the product arrives at the customer, we use three different indicators for product quality inspection to avoid quality problems in the products produced by the CNC machining process.

1. Predictive Quality Analytic

CNC machines are widely used in the manufacturing industry, and each product has different quality specifications contained in technical drawings or product drawings. Indicators to analyze the quality of a product can be seen from the performance of the machines and tools used, the accuracy of the size and the CAD/CAM method used so that it can be seen visually the surface of the product and the resulting smoothness. To predict the quality of CNC machining products, proper analysis is needed, including CNC machine parameters, in which there are settings for engine speed (RPM), cutting speed (CS), or feeding depth (DOC). This makes the surface smoothness of the production so that it is effective and efficient.

2. Machine Vision Quality Control

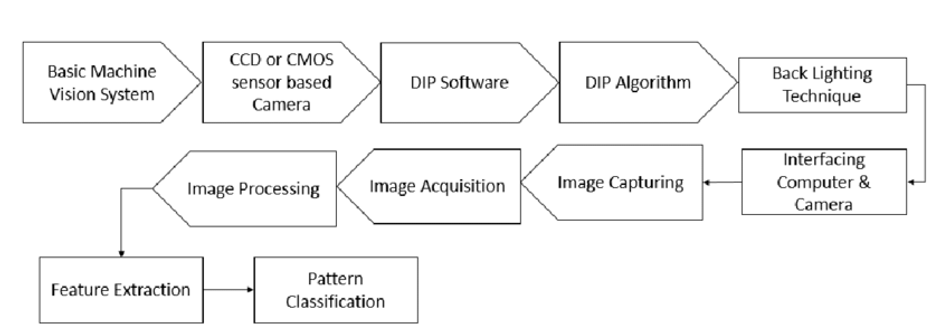

Observations on machine parameters can be monitored and measured by looking at the condition of the tool, tool wear and material characteristics, it will affect surface roughness and surface defects. The development of methods to monitor machine parameters can be done by the method in the picture below. This monitoring is to see the condition of the equipment used to ensure quality control is achieved.

Basic Processes of machine vision techniques

3. Standard Operational Procedure (SOP)

SOP is a standard procedure for operating a CNC machine so that the machine can operate properly without accidents resulting in losses, or standards made for production as guidelines for producing quality products. Effective SOPs can reduce production costs, work will be more effective and efficient, save tools and extend machine life, and be implemented with appropriate documentation so that the performance achievements are achieved by every worker. An effective SOP can encourage work improvements and reduce product defects so that losses can be minimized so that work can be efficient. In the United States, SOP is also an important element of the prerequisite programs required under the ISO 9001 Standard audit scheme and other safety and quality systems.

Maximizing the Benefits of Metrology Fixturing

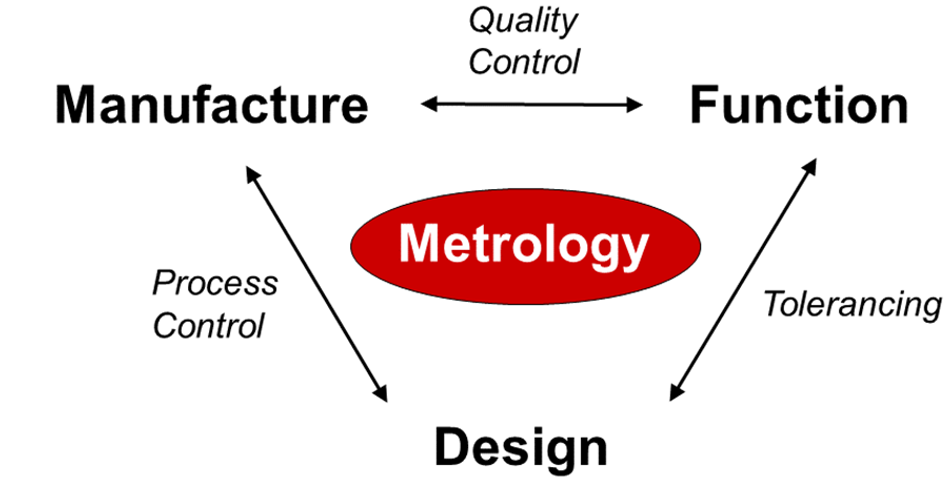

Metrology is the science of measurement used in CNC machining, many measuring tools are used to check the size carefully and thoroughly including caliper, micrometer or CMM to achieve precise accuracy. The image below describes how the science of metrology has become the center of study for producing various manufactured products

Centered on the metrology of all production activities.

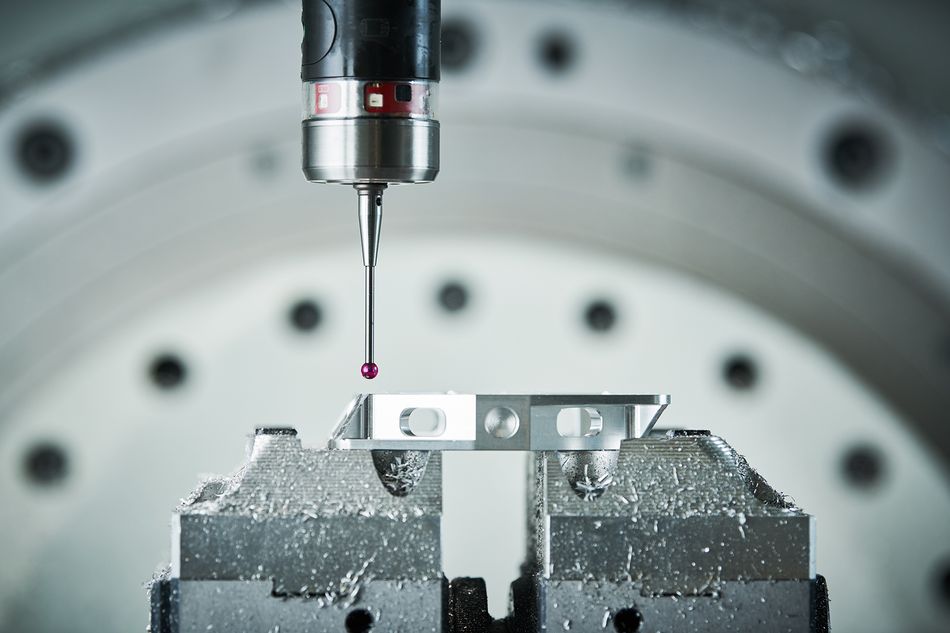

The benefits of installing a proper metrological measurement and it can significantly affect the efficiency of the inspection process are largely neglected. It is common for equipment to be neglected until the last minute of a project, or even worse, completely forgotten. Only when the CMM backlog begins to form or the metrological results drift, the focus is drawn to the assembly of parts and positioning within the machine. At that time, generally at the expense of lost time and money, and the costs of retrospectively implementing appropriate control measures increased. Many advantages can be obtained from the right metrology to produce quality products.

Reaping Benefits of Evolving ISO 9001 Standards

ISO 9001:2015 is also a standard requirement for quality management systems, providing 2 benefits, namely external and internal. Improved performance, market penetration and customer satisfaction are some of the external benefits. Today's business world is required to always improve performance and performance so that its products/services or systems can be accepted by all parties. Therefore, a quality management system is very important for a company, with good and consistent quality processing it will improve the quality of production which in the end will reap maximum results. Here are some importance of Having ISO 9001 Certificate you can know:

1. Guarantee the quality

ISO 9001 certificate will assess the quality as well as the quality provided by the company. So that customers who cooperate with companies with ISO 9001, will certainly get quality assurance and quality that is continuously improved. The ISO 9001 certificate will continue to be improved and assessed on an ongoing basis so that consumers will receive improved services.

2. Increase Customer Trust in the Company

The trust given to companies that have implemented ISO 9001 in business entities will certainly increase. Therefore, large companies generally only want to work with companies that already have ISO: 9001 Certificate on quality management systems. The importance of this ISO: 9001 certificate is to legalize the company's activities in the international world and maintain the company's good reputation. Customers or partners will be comfortable working with companies that already have this certificate.

3. Guarantee Customer Satisfaction

One of the main objectives of the ISO: 9001 Standard is to provide satisfaction to customers in accordance with international regulations. By implementing an internationally standardized management and quality assurance system, companies can certainly remove unnecessary management barriers and improve them. These obstacles can affect the performance of the company as a whole from the level of subordinates to superiors so that it interferes with the company's performance.

4. Documented system

Documentation of every work process is one of the characteristics of a company that has advanced and developed. ISO 9001 certification will assess whether the documentation carried out by the company is in accordance with the established standards. This is in contrast to companies that have not implemented ISO 9001, in general, will be careless with their work files and are not well documented.

Conclusion

Producing machined parts with CNC can increase productivity and production effectiveness, setting machine parameters correctly will produce precise, accurate and quality products.

Investment in CNC machines will not be a loss because the size of the work currently requires CNC with high technology to support the work so as to increase production speed and save production costs.

To get good CNC performance, adequate maintenance and proper machine settings are needed so that the resulting product is of good quality.

Production quality is obtained by following the correct and continuous SOP instructions so that maximum results can be achieved, accurate measurements can improve the quality of high-precision products.

It is necessary to have an ISO: 9001 certificates which is internationally recognized for every company which aims to increase trust in customers so that there will be many orders.