How we test 3D printing material combinations

At Ultimaker, we rigorously test our materials to provide the best possible results. Not only to ensure excellent mechanical and aesthetic properties, but also so that the preconfigured settings in our Ultimaker Cura software offer a hassle-free 3D printing experience.

At Ultimaker, we rigorously test our materials to provide the best possible results. Not only to ensure excellent mechanical and aesthetic properties, but also so that the preconfigured settings in our Ultimaker Cura software offer a hassle-free 3D printing experience. In this blog we give an insight into this process and look at how we test and develop various combinations of 3D printing materials.

Having preconfigured profiles in our software makes it easy for users to start printing without any delays. Our materials and processing engineers look at a number of factors when optimizing material profiles. From the type of printer and nozzle size to needs like speed and strength, there are certain criteria that must be met before a profile is added to Ultimaker Cura.

This same rigorous process has also been applied to developing composite material profiles (printable on the Ultimaker S5), in collaboration with world-leading material manufacturers – including Owens Corning.

Behind preconfigured material profiles

In order to refine a material’s optimal printing settings, first the team establishes a baseline for recommended settings, like nozzle and bed temperature.

Then, an extensive testing and evaluation process ensures that print profiles are optimized. Material parameters such as temperature and fan settings are all analyzed and adjusted accordingly. The team also looks at the relevant speeds, wall thickness, line widths, infill, and acceleration to help set up the right material profile. Finally, a series of test prints are made to check issues like layer splitting, warping and oozing.

Creating the perfect profile

Ultimaker Cura offers over 300 possible settings. For our preconfigured profiles, these settings have been designed to take the guesswork out for you, so you can print reliably without the need for a lot of experimentation and manual configuration.

Of course, using your own custom settings is also possible, depending on what you’re trying to do with your print. For dual extrusion prints, there are also setting options for both extruders in Ultimaker Cura, so you can adjust these individually.

Combining two materials

With a dual extrusion printer like the Ultimaker S5, you can print items using two materials. This is particularly useful when it comes to support materials like Breakaway and PVA. However, it’s important to remember that some materials combine better than others due to their properties.

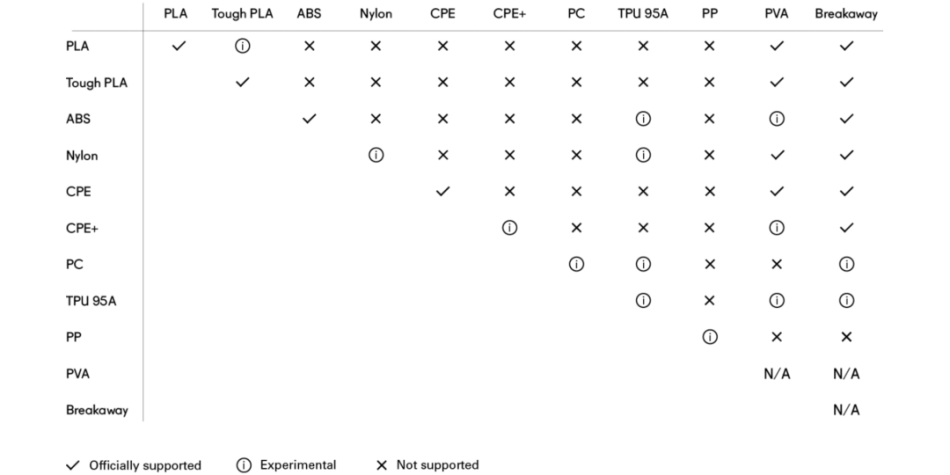

Breakaway has been designed as a support material that adheres well to other materials like PLA, Tough PLA, Nylon, ABS, CPE, and CPE+. PVA combines well with PLA, Tough PLA, Nylon, and CPE.

This diagram shows officially supported, experimental, and not supported material combinations. Officially supported materials can be used together reliably without problems. Experimental materials can be used together, but may not give reliable results that meet our quality standards. Materials that are not supported cannot be used together.

One of the most commonly used materials, ABS, is not recommended to print with PVA as it has a tendency to warp at the point between the two materials. So if you need to support an overhang on an ABS print, you can use our removable Breakaway support material instead.

When TPU 95A is combined with another material, it can result in negative artifacts on the print called ‘oozing’ due to its flexible nature. Some material combinations experienced more oozing than others. These are marked as unsupported, rather than experimental.

PP, while a useful material due to its fatigue-resistant properties and widespread use in manufacturing, struggles to stick to anything other than itself so it is not recommended in dual extrusion prints.

Another factor to consider with dual extrusion prints is the nozzle size that is used. For instance, printing Breakaway with a 0.25 mm nozzle results in support material that is not easy to remove and may cause damage to the print if too much force is applied. When in doubt, always refer to the compatibility tables.

While some material combinations are technically printable, due to a lack of practical applications not all combinations have been fully explored, which is why some of our combinations are marked as not supported.

Trying out new materials and discovering how different settings work can be useful if you are working on a unique or unusual project. For reliable printing, however, preconfigured printing profiles can save a lot of time. Knowing which materials can be combined, and which ones don’t work so well together, can help you in producing prints that meet your needs.