Make it Real 3D Printing Challenge Finalists Announcement

We announce the eleven shortlisted finalists of the Make it Real 3D Printing Challenge.

The Challenge

Wevolver and polySpectra invited designers, inventors, and engineers from across the world to submit ideas to the Make It Real 3D Printing Challenge. We were flooded with incredible entities from all corners of the globe proposing innovative ways to use polySpectra’s flagship additive manufacturing material, COR Alpha. After a tense deliberation process, we are proud to announce the ten shortlisted finalists. Each of the following designs was considered by the jury to have valid design integrity and provided a compelling utilization of COR Alpha.

The Finalists

RED Ventilators

“We are designing the world's most capable, reliable low-cost ventilator technology to be freely licensed to low-income countries,” says RED ventilators co-founder, Mohan Gurunathan. Mohan along with his co-founder Edward Edward Ayrapetian had been working as design consultants on a ventilator project for 4 years before the COVID-19 pandemic began. “When COVID-19 started, there was a flurry of well-intentioned ‘home-brew’ ventilator projects which popped up to solve the world-wide ventilator shortage,” they explain. “We quickly realized that many of these projects (especially those based on Ambu-bag squeezing) would not work well - mechanical ventilation is much more complicated than can be implemented with a simple bag squeezing device. Given our background in the field, we decided we should try to come up with a solution as well. We have developed an architecture that provides most of the features of ICU-class ventilators with 1/5th the price tag. We're now working with potential licensees in Nepal and several other countries.”

Team WrapEZe

The founder of Team WrapEZ, Dr.Yvonne Cagle, combines 3 decades of experience as an astronaut in the space industry with a drive to sustain the human species as we strive to thrive. WrapEZe is a cutting edge, wearable wrap technology that accelerates human restoration from injury and aches.

“This cutting edge wearable wrap technology for accelerated recovery - made real, moded for space--is now available to help humanity from the working wounded to the aspiring athlete, explain Yvonne. The buckle, which is Team WrapEZE’s entry to the Make it Real Challenge is a key component part of the novel adaptive wearable technology. “Rapid and robust adaptive prototyping enables the “on-call“ precision in the WrapEZe component rig-design customizations for personalization, sustainability, repurposing, and evolution,” says Yvonne. “In navigating the restorative edge of Potential Human it doesn't get more “Real” than sustaining the human species as we strive to thrive off planet. Our collaboration is an opportunity for the WrapEZe transformation to permeate throughout the “performance” universe as a force multiplier, together - and beyond…..Let's Make It Real!”

Sun Geometry

“We are reinventing solar electricity generation products via intelligent system design,” explains Sun Geometry team lead Mark Perlin. "We have designed a smart sun-tracking miniature robot that optimizes photovoltaic (PV) solar system performance by integrating the highest efficiency PV solar cells into a smartly designed concentrating mirror geometry that is aimed precisely at the sun by small motors. Although the majority of the parts are made by 3D printing or laser cutting. Our goal is to bring optimized high efficiency, high sustainability, sun-aligned solar electricity systems that improve the charging experience by shortening solar charging times for everyday electronics.

The Sun Geometry team hopes to use the collaboration with polySpectra to further refine their design and connect to a wider network of engineers. “3DP is a great fit for prototyping our product, but in order to increase to pilot production volumes, we need help to optimize all aspects in order for 3DP to be competitive with other production processes and materials,” says Mark. Also, we want to collaborate broadly on optimizing the system and welcome connecting with other makers, builders, and designers.”

N+ Bike Shoe Platform

In exciting news for bike enthusiasts, the N+ Bike Shoe Platform are working on the world's first additive-enabled performance bike shoes. “It's an open-source hard goods project exploring the potential of digital manufacturing and changing expectations of product ownership,” team leader. Marcs Wilkinson told Wevovler. The design is fully modular, repairable, and customized with a 3D printer and sewing machine.

The team was really excited to discover the properties of COR Alpha. “Printing a part rigid enough to replace the composite core of performance cycling shoes isn't possible using traditional FDM materials,” explains Marcs. “Getting around this involved a messy composite layup in a printed mold. Producing an end-use part that meets performance requirements through additive manufacturing would showcase the potential of 3D printed product design for consumer goods - replacing multi-material and tough to dispose of cycling shoes with a modular, printable system that can be built on demand by the additive factory of the future, and recycled, re-manufactured or updated throughout the product life cycle.”

Simon Tirapelle - building a yacht from scratch.

For many who experienced strict social distancing regulations, 2020 has provided a time for new projects and introspection while being away from many of the other activities and events we were used to. This is especially true for Italian highschool student Simon Tirapelle who earlier this year decided to cement his love for sailing by designing a way to build a small racing yacht from the ground up. An integral part of any sailing vessel is a pulley to adjust the sails. This is the element Simon entered to the Make it real Challenge. “A pully has to be strong and resistant,” says Simon. COR Alpha is perfect because of strong this material is. Another big deal, is its ability to deal with exposure to seawater.”

Trillium Technologies [FuelPod]

“Our project aims to improve NASA’s foam liner design on future lithium Ion battery packs for space applications - particularly NASA’s Artemis mission to the Moon,” explains the Trillium team. “By doing this we are adding enhanced specifications of this component to make it more suited to deep-space applications. For example mass reduction, system safety gains, easier manufacture and reduced sensitivity to rapid temperature variation. This design optimizes a combination of multiple components, resulting in strength improvements, higher impact resistance, future proofing for in space manufacture and maintenance, as well as advanced functionality such as liquid cooling and generative design optimization.”

Trillium were impressed with the high resolution of polySpectra’s 3D printing process and the mechanical qualities of the COR Alpha material, in particular, the usable temperature range, shock resistance, and toughness. “As a company we have always extensively used 3D printing in our prototyping process and relish the opportunity to test ideas using the state of the art printing processes and materials,” the team says. “We hope to be able to help champion the technological advancements in the sector of 3D printing again.”

Evol Components

EVOL Components design motorcycle parts that are truly evolved for their function. “Through utilizing 3D printing and biological forms the ‘Vertebrae Indicator Bracket’ offers a new level of efficiency and high performance,” says Heath Townsend from Evol Components. “I truly believe in pursuing design and 3D printing for final products, not just as a prototyping aid. PolySpectra play a massive role in this pursuit. The COR Alpha material offers strength, heat resistance, exceptional surface finish, and is the perfect match for a new level of motorcycle components.”

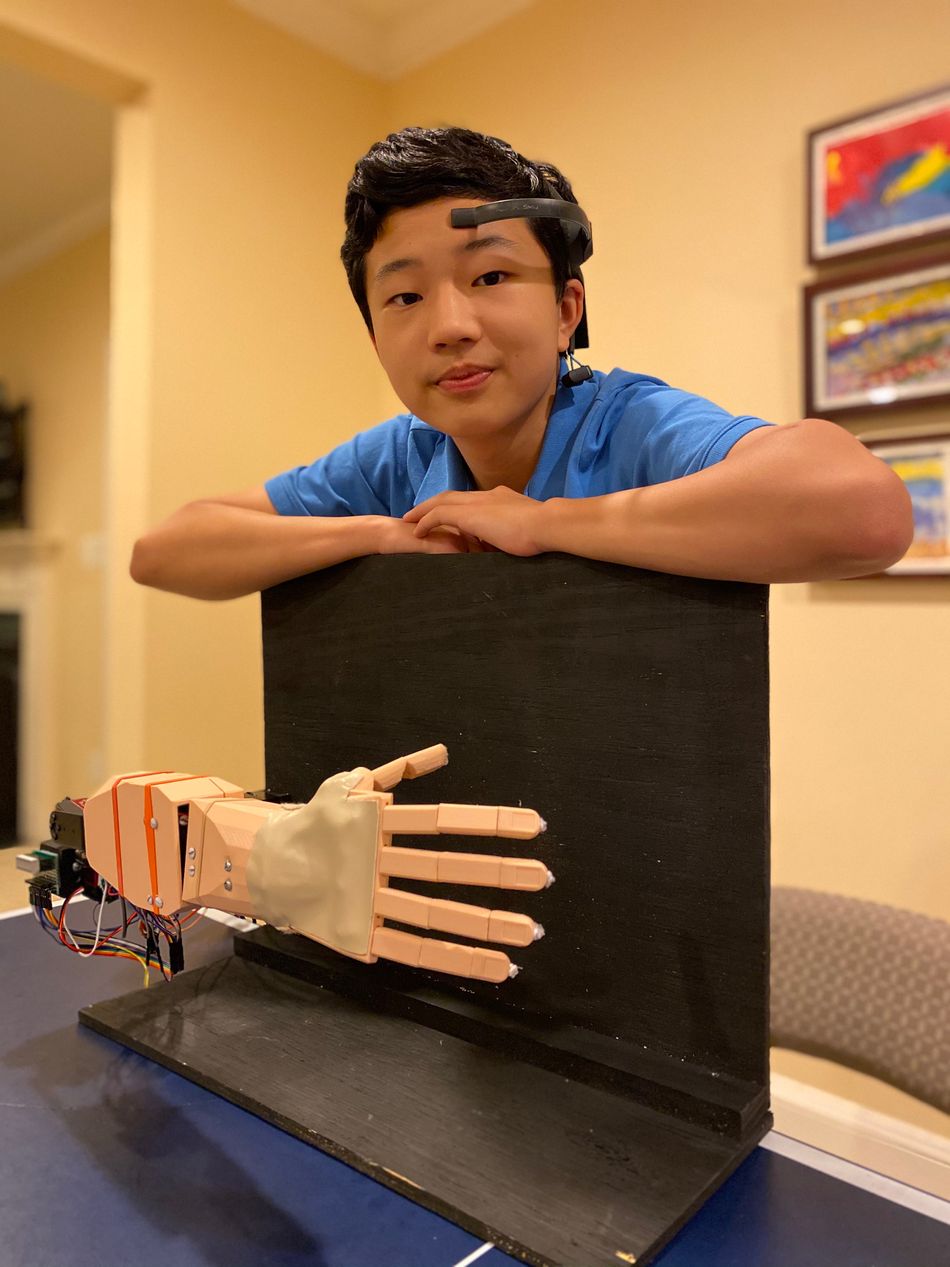

Ben Choi: An ultra-low cost, brain-controlled prosthetic limb

“I developed a low-cost prosthetic arm controlled by a combination of brainwaves and subtle head gestures,” says Ben Choi the incredible American Teenager behind this design. "The arm uses an EEG scalp electrode which picks up signals from within the brain and sends them via Bluetooth to a small receiver within the arm; a special algorithm then processes and translates these various signals into motion. With the exception of a few electronic components, the arm is entirely 3D printed, and the current model is capable of moving four different joints (dual axis elbow, wrist, and hand) and performing a variety of complex tasks such as transferring objects between containers and pouring a glass of water. Since prosthetics typically undergo rigorous daily use, they must be built with an appropriately rugged set of materials. While my current model is mechanically functional, the arm’s durability must be improved before the prosthesis can be used in a real-life setting. As COR Alpha is extremely strong and resistant to physical and thermal damage."

"The Make It Real Challenge presents an incredible opportunity for me to catapult my arm out of the prototyping phase and into end-use application. The many months of quarantine allowed me to devote considerable time toward integrating these two concepts into a single potential solution; while current prostheses can cost in the tens and even hundreds of thousands of dollars, my brain-controlled arm costs less than US$250 to produce. With the help of polySpectra and COR Alpha, I hope to continue to iterate toward a prosthesis that is accessible to all.”

Doctor Zulty and Doctor Kovalik + DiveDesign

Sparying or neutering animals is a common practice for good health and population control. Two experienced vets have joined forces to rethink the tools performing ovariohysterectomies (spay procedure) to improve veterinarian's speed, accuracy, and comfort. While in the process of developing their device, Dr. Zulty and Dr. Kovalik and the Dive Design team found that utilizing injection molding would pose the following issues: the price for tooling was not warranted for low-volume manufacturing (for user testing), the materials available were too slippery (would not provide a solid hold onto the clamp), and they would not have any options for creating a multi-density product (which would be beneficial for fine-tuning the weight of the product) using a single material.

“Due to these reasons, there is a need to transition towards Additive Manufacturing for production,” explains the team. “As veterinarians ourselves, we know the value that this device could provide to countless others in our field, and we have made it our mission to create the perfect "spay assist" device,: they say. “In addition, as an assistive surgical tool, there is potential to utilize this device in other surgical procedures. This simple tool could provide value to veterinarians who perform spay procedures and decrease the surgical risk for the dogs that undergo them,” the team concludes.

ARCH Ventures

“Glaciale is the world’s first digital ice drinking glass,” Arch Ventures Patrick Astarita tells us. “Simply pair it with any wireless charging device, pour in your favorite warm beverage, and then enjoy a crisp, thirst-quenching drink without any dilution. When you’re done, you can remove the cooling lattice from the base of the glass and toss them both in the dishwasher.

At the heart of the Glaciale is our proprietary heterogeneous vapor compression–phonothermal cooling technology which would not be possible without photopolymerizing additive manufacturing. The Make it Real Challenge will provide us with the resources to iteratively prototype at the technical forefront of materials engineering and integrated systems design. Beyond the active cooling drink glass: We aim to develop a robust, inexpensive cooling module that we believe will revolutionize thermoregulation in every aspect of life in the world around us.”

Design It Yourself Glasses

Despite glasses-wearing enjoying an extended hip moment, when it comes to frames selection there is a lot to be desired. Enter Kianoosh Ghaffarzadeh Vejdani who has created a method to design your own unique eyeglasses frames. “An algorithm is designed to generate 3D glasses frames with a few parameters. The user/customer can shortlist recommended glasses and play with the parameters in order to design his/her own desired glasses in an interactive process,” explains Kianoosh.

“At the same time the data received from the users trains the recommendation system to give better suggestions based on their face shapes.They are unique virtual 3D modeled glasses. To Make them Real we need a production system that can make one pair for each person with the quality of a real pair of glasses, not prototype. COR Alpha seems to have those qualities. After learning about Parametric Design a couple of years ago, I used it mostly to make particular design tools for my modeling projects. I always wanted to use it in a more design-based way to help the process of design, rather than using it in fancy organic form generating. I came up with this idea for my Masters in Design Thesis Project. Glasses frames are highly personal products in the matter of form, and yet they are not very complex and advanced products, which makes them perfect for my goal. This idea is not only about the product but about the process. It tends to make a new approach to design and production. My project was about the design part of it. The production part completes my project.”

The next steps

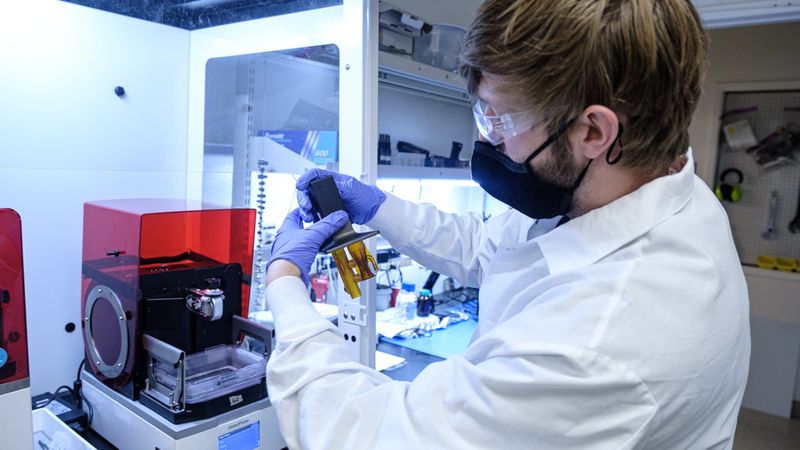

CEO of polySpectra, Raymond Weitekamp, and his team in Berkley California are working with the finalists on prototyping. The next round of judging will examine the entries looking for strong collaborative projects that showcase additive manufacturing and COR Alpha. The final winner/s of the challenge will be announced soon!

About the Sponsor: polySpectra

polySpectra is an advanced materials company on a mission to transform polymer 3D-printing from a prototyping aid into a production manufacturing tool. polySpectra has developed a new class of modular light-activated resins, unlocking a broad spectrum of tailored engineering properties for production-grade additive manufacturing. We call this new family of additive materials COR, for Cyclic Olefin Resin. polySpectra’s first material, COR Alpha, demonstrates an unmatched combination of thermal, mechanical and chemical properties that enables additive manufacturing to compete with injection molding. polySpectra's technology is based on more than five years of chemical research and development at two leading research institutions: Caltech and Lawrence Berkeley National Laboratory. Based in Berkeley, CA - polySpectra helps inventors, designers and engineers make their ideas real.