On the fast track with woven wire cloth: Mesh components for technological progress in the automotive industry

Technological progress means optimizing the smallest components to improve efficiency and safety. In addition to digital features, intelligent software and new assistance systems, developers and engineers are also focusing on classic vehicle technology such as engines and transmissions.

The automotive industry is a very dynamic sector. Technological progress means optimizing the smallest components to improve efficiency, environmental standards and safety. In addition to digital features, intelligent software and new assistance systems, developers and engineers are also focusing on classic vehicle technology such as engines and transmissions. Wire mesh components from Haver & Boecker play a decisive role here.

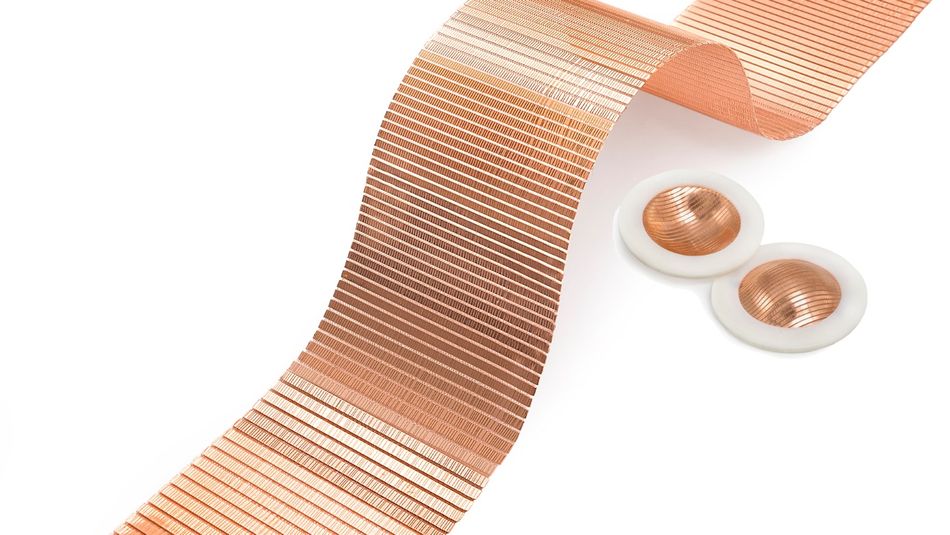

Filters and moulded parts made of wire mesh are key components in vehicle technology and are used in a wide variety of applications. They filter and regulate fuels and operating fluids, protect sensitive technology and contribute to the individual design of the interior. Their versatility is particularly evident in the wide range of designs, materials and wire thicknesses available. This enables engineers and developers to create optimum solutions for the end customer.

Product components in practice

- Filters for petrol direct injection systems: Wire mesh is the optimum medium for retaining unwanted particles in the engine. A hybrid filter with ultra-fine metal wire mesh retains particles larger than 15 μm. The special weave allows high fuel flow with low-pressure drop and provides the required strength.

- Piezoelectric sieve electrode: Common rail injection uses the conductivity of metal wire mesh to save fuel. A sieve electrode transmits the electrical voltage to the ceramic layers, allowing optimum metering of fuel. This reduces exhaust emissions and protects the environment.

- Filters for low-pressure exhaust gas recirculation: Wire mesh LP exhaust filters reduce nitrogen oxide emissions. They must be extremely heat-resistant and at the same time not obstruct the flow of exhaust gases. A specially developed 3D mesh reduces pressure loss and ensures high particle absorption.

High demands on the smallest components

Wire mesh components must be extremely fine, precise and flexible, while also being able to withstand high pressures and temperatures. Innovative manufacturing processes and careful development, production and testing enable the production of materials that are precisely tailored to the automotive industry – and are often superior to conventional solutions in terms of efficiency and reliability.

Other applications: EMC and design

In addition to filters and flow straighteners for exhaust gas turbochargers, wire mesh is becoming increasingly important in the field of e-mobility, particularly due to its shielding properties against electromagnetic interference signals.

Designers also recognize the benefits in terms of the design and aesthetics of vehicle interiors: the durability and strength of the product make it the preferred choice for car manufacturers who focus on both design and functionality. Metal mesh is used to create vehicle interiors such as seat covers and door panels, adding a luxurious touch with its high quality and aesthetics.

Whitepaper on the topic

For an in-depth look at how wire mesh can be used in the automotive industry, download the free white paper. It will tell you more about the technological advances made possible by wire mesh components and provide valuable information on the latest developments and applications.