Open Bionics: 3D printed prosthetic limbs

Open Bionics is creating the next generation of prosthetic limbs. What sets these apart from traditional prosthetics is that all of the mechanical parts are 3D printed, bringing along considerable cost-savings.

Open Bionics is creating the next generation of prosthetic limbs. What sets these apart from traditional prosthetics is that all of the mechanical parts are 3D printed, bringing along considerable cost-savings. The models created by Open Bionics are both functional and aesthetically pleasing, making sure its wearer feels comfortable wearing them - both physically and socially.

Bionic hands can be very expensive. Starting at about $35,000, they can go up to even $120,000. Open Bionics is developing a bionic hand that offers the same functionality at under $1,200.

The 3D printed prosthetic

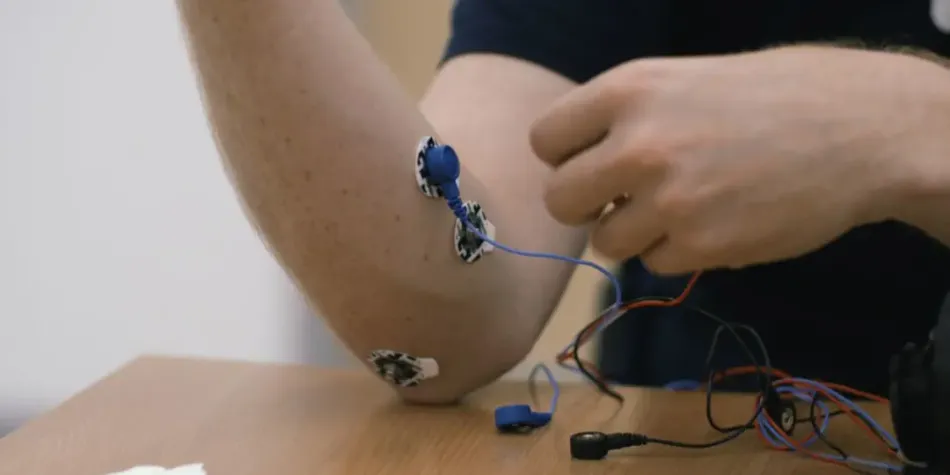

The Open Bionics hand is suited for trans-radial amputees: people that still have an elbow joint but miss anywhere from their hand upwards. The prosthetic works through sensors that are placed on the wearer's muscles. These send out an electric signal that allows the hand to move when specific muscles are flexed. Each finger can be moved independently and with varying speed, allowing for different gripping modes and movements to be made.

3D printing plays a vital part in the development of the Open Bionics hand. After 3D scanning the wearer's residual limb, a prosthetic design is made in 3D modeling software, after which both the hand and its socket are 3D printed.

As all the mechanical components of the hand can be 3D printed, it becomes a cost-effective alternative to the traditional, expensive prosthetic. As it's about 30 times cheaper than other available alternatives, it helps to make robotic hands accessible to a wider audience.

Rigid and flexible materials

The Open Bionics hands are created using both rigid and flexible materials to support the varying functionalities of different parts of the hand. The fingers are printed in one piece with flexible TPU and have joints built-in that work directly after the printing has finished. Other parts, that need to be more rigid, are printed with PLA. Since the fingers' joints are built-in, the number of different parts that need to be manufactured is greatly reduced, which simplifies the assembly process.

3D printing not only shrinks the development costs of these bionic hands - it also allows for tailor-made designs to be implemented that perfectly match the wearer's wants and needs. Check the Open Bionics website to stay up-to-date on the progress made in this field.

As this case illustrates, 3D printing can radically change the way in which medical applications are approached. For an overview of other 3D printing applications in the medical field, check out our explore pages: https://ultimaker.com/en/explore/where-is-3d-printing-used/medicine

Disclaimer: Ultimaker 3D printers are designed and built for Fused Filament Fabrication with Ultimaker engineering thermoplastics within a commercial/business environment. The mixture of precision and speed makes the Ultimaker 3D printers the perfect machine for concept models, functional prototypes and the production of small series. Although we achieved a very high standard in the reproduction of 3D models with the usage of Ultimaker Cura, the user remains responsible to qualify and validate the application of the printed object for its intended use, especially critical for applications in strictly regulated areas like medical devices and aeronautics.