Unlocking the Potential of Digital Twins for Aerospace Manufacturing: New Webinar

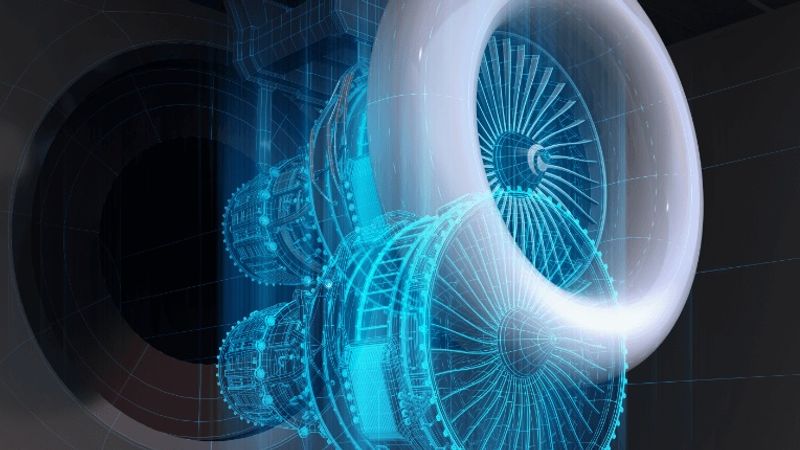

Discover how digital twins are revolutionizing aerospace manufacturing by cutting design cycles, driving predictive maintenance, and improving manufacturing efficiency.

The aerospace industry faces growing challenges, from managing complex supply chains and rising operational costs to meeting stringent regulatory demands—all while striving for greater safety, efficiency, and cost reduction. Traditional methods are falling behind, resulting in lengthy design cycles, costly prototyping, and interoperability issues. To stay competitive, companies are increasingly adopting digital twin and digital thread technologies to drive innovation and operational excellence.

In the webinar "Unlocking the Power of Digital Twins for Aerospace Manufacturing," Quest Global, with over two decades of experience in digital transformation of both aerospace and defense manufacturing, shared expert insights on how these technologies are transforming the industry. If you couldn’t attend the live webinar, you don’t have to miss out. Access the on-demand recording of the webinar now:

Leading the Transformation in Aerospace Innovation: How Quest Global is Revolutionizing Aerospace with Scalable Digital Solutions

Spearheading this digital transformation across two decades, Quest Global has a proven track-record of successful implementation of scalable digital solutions in the aerospace and defense industry. In this webinar Head of Engineering, Nick Charles and Head of Advanced Manufacturing CoE Vijay Anand, from Quest Global will sit down with tech writer Samir Jaber to unpack how aerospace manufacturers and Original Equipment Manufacturers (OEMs) are leveraging digital twin technology and digital threads to enhance operational efficiency.

Who should watch this webinar?

This webinar is designed to provide aerospace engineers, manufacturing professionals, and decision-makers looking to optimize their production processes with actionable insights into the transformative power of digital twins. By attending, you'll gain practical knowledge on using digital twin technology to boost efficiency, reduce costs, and improve overall aerospace operations, making it a must-attend event for those looking to stay competitive in the industry.

Why you should watch it:

Learn Cutting-Edge Techniques: Discover how digital twins can transform aerospace manufacturing by reducing non-conformance, improving process efficiency, and optimizing designs with predictive analytics.

Enhance Decision-Making: Understand how integrating digital twins into aerospace supply chains enables real-time decision-making for better outcomes and reduced downtime.

Gain Competitive Advantage: Stay ahead by learning to leverage digital twins to streamline operations, boost productivity, and drive innovation in the aerospace industry.

Explore more details of the webinar below:

This webinar will cover how digital twins and digital threads are revolutionizing aerospace manufacturing by bridging the gap between design and production. Nick Charles, Head of Engineering at Quest Global, and Head of Advanced Manufacturing CoE Vijay Anand, will share expert insights on the importance of real-time synchronization and collaboration using these technologies. The session will include a case study demonstrating a successful implementation that led to significant reductions in cycle times and improved efficiency. By attending you will also gain actionable insights on how to begin integrating digital twin and digital thread solutions into their own operations, streamlining processes and fostering innovation.

Key insights include:

Cutting the Design Cycle: Learn how digital twins help identify design issues early, verify interfaces, and conduct simulations of environmental behaviors and characteristics, drastically reducing design times and errors.

Optimizing Manufacturing Methods: Discover how digital twins can improve the design of manufacturing tools and methods, enabling the use of Virtual and Smart Factories to boost production efficiency.

Enhancing Predictive Maintenance: Gain insights into how digital twins enable real-time data analytics, helping to predict and prevent failures, extending equipment lifespan, and optimizing operational efficiency.

Speaker details

Nick Charles Head of Engineering - UK Defense at Quest Global Nick Charles is the Head of Engineering (UK Defence) at Quest Global and a seasoned engineering leader with extensive experience in the aerospace and defense sectors. Previously, he served as VP and Senior VP at Ultra Maritime, leading a team of over 800 engineers across five countries. Was responsible for challenging engineering projects and drove major improvements in engineering processes, team development, and risk management |  |

| Vijay Anand R (VJ) GM – Head of Advanced Manufacturing CoE at Quest Global VJ is Head of Advanced Manufacturing CoE of Quest Global based out of Derby, UK.He is a veteran of Manufacturing Engineering for over 30 Years, both with Traditional and Digital manufacturing. He is heavily influenced by Toyota way of working and embraced the same in his roles at Quest Global while managing Global manufacturing team and solutions for major Aerospace & Defense, Energy and Transportation customers till date. He has been instrumental in setting up a Digital Manufacturing Lab in partnership with Siemens to Design, Develop and Simulate the manufacturing and assembly operations. He also represented Quest Global for a Major Aero Engine customer’s Digital Manufacturing Focus Group conferences held at various global locations. |

Luke Logan Luke Logan is a seasoned business leader with a significant career in engineering and technology. With over three decades of senior executive experience, Luke has led global teams and managed major projects at Rolls-Royce plc, BAE Systems plc, and Weir Group plc—three of the world's leading engineering and technology companies. His broad expertise across sectors such as Civil Aerospace, Defence, Power, and Industrial Equipment enables him to share a wealth of insights and foster diversity of thought.Now, as an independent advisor and consultant, Luke applies his extensive experience to support the growth and development of his clients' businesses. He is deeply committed to diversity & inclusion, innovation, and aligning engineering professionalism with business success and sustainability. Luke is a Fellow of The Royal Academy of Engineering, the Institute of Mechanical Engineering, and the Royal Aeronautical Society. |  |