Revolutionizing Drone Production with 3D Printing

How Fiberthree, Drywise, and the Auriol drone by Third Element Aviation take flight

Third Element Aviation's high-performance drone Auriol

The Drone

Third Element Aviation is a pioneering force in Germany’s high-performance drone industry. Their latest creation, the Auriol, is a highly customizable drone known for its durability, adaptability, and performance. Designed with the intent of revolutionizing various sectors such as industrial inspections, surveying and mapping, security and emergency services, and especially logistics the Auriol has become an industry benchmark for high-quality, reliable drones.

In the realm of drone technology, the quality and reliability of each component is paramount. A single failed part can compromise the drone’s overall performance, potentially resulting in missed data, inaccuracy in mapping or imaging, or worse, complete drone failure in mid-flight

The Challenge

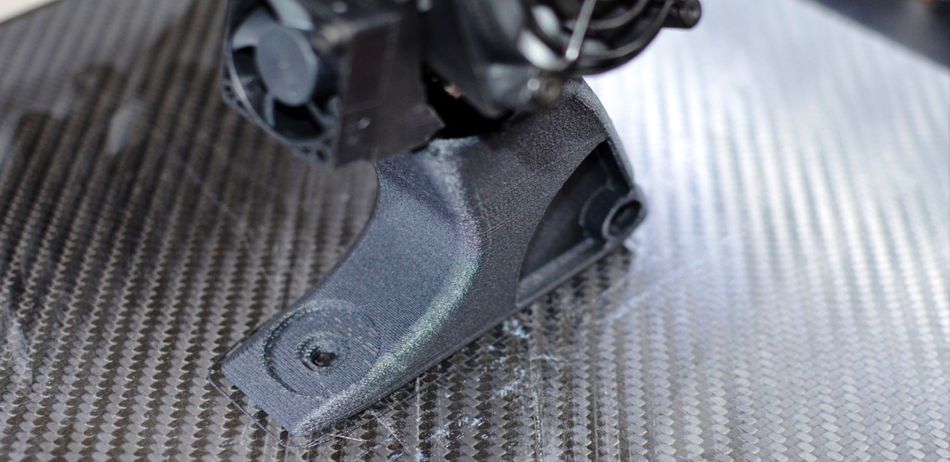

For Third Element Aviation, meeting the needs of individual applications and customized solutions while also enhancing the quality and reducing the production time of their drone components was a significant challenge. Components that constitute parts of the backbone of Auriol drones and other critical components benefit from 3D printing. These components are not only essential for ensuring the overall stability and performance but also pivotal in managing the sheer weight of this formidable 25kg industrial drone.

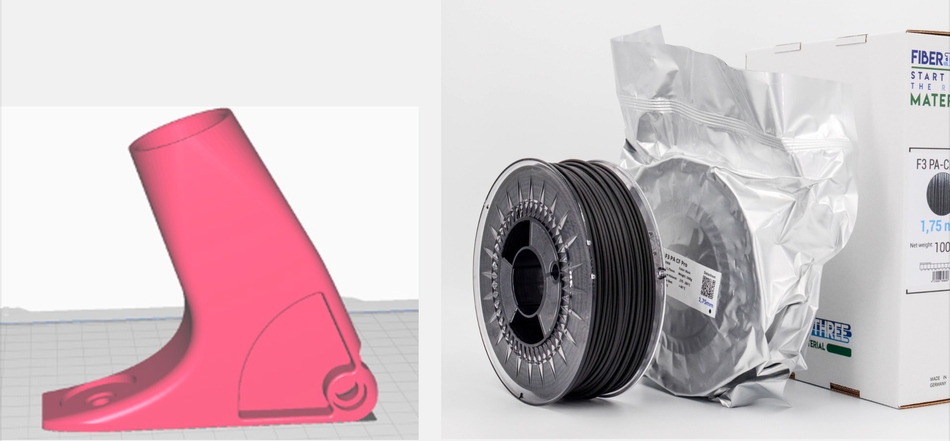

All in-house made components were printed using Fiberthree’s F3 PA-CF Pro, a carbon fiber-filled nylon renowned for its strength and resistance to high temperatures, making it the ideal filament for the application. However, due to its hygroscopic nature, it was prone to absorb moisture from the environment, which could lead to inconsistencies in the 3D printed parts, affecting production, product quality and consequently the drone performance.

The Solution

Fiberthree, despite being meticulous in its production process, understood that it needed a solution that could control the often-unpredictable user end of the process. The company makes every effort to ensure its F3 PA- CF Pro material leaves the factory in an optimal state. They meticulously dry their materials after production and pack them securely in moisture- resistant packaging to mitigate any potential humidity absorption. However, once the material reaches Third Element Aviation, new humidity could be introduced, which has the potential to compromise the print quality.

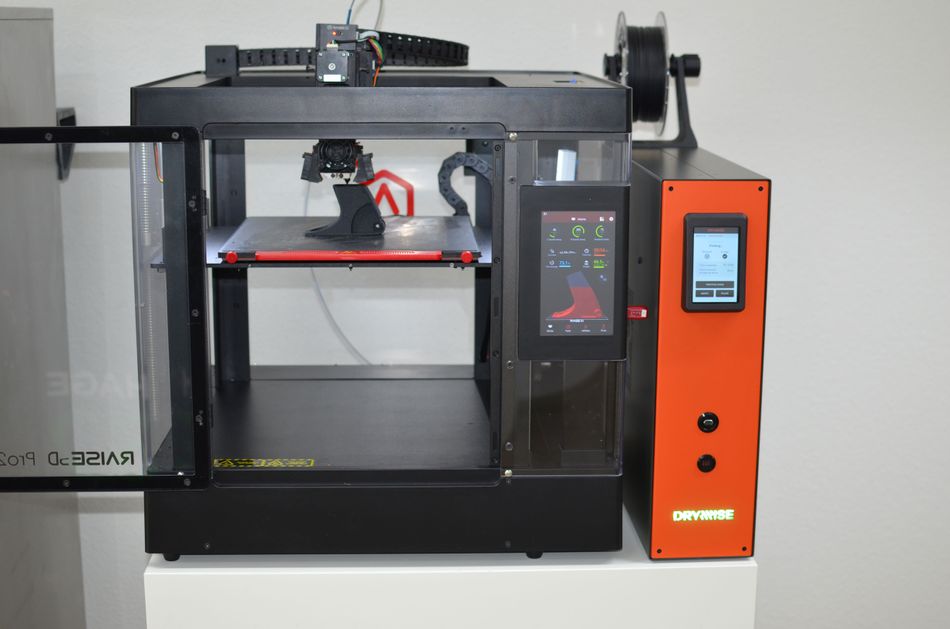

Recognizing that the user end of the process was out of their direct control, Fiberthree suggested a unique solution: Drywise. This innovative in-line filament dryer offers the key to maintaining the ideal moisture content during the 3D printing process itself, regardless of external factors at the user side. Drywise continually dries the filament during the 3D printing process, ensuring that optimal moisture content is maintained, and that the integrity of the final product is ensured.

The Results

Integrating Drywise into their production process proved to be a game-changer for Third Element Aviation. The benefits were immediately tangible:

Reduction in drying time

The previous 12-hour or weekend-long pre-printing drying times were now eliminated. The filament was dried during the printing process, resulting in significant time savings.

Improved consistency in print quality

The consistent drying ensured by Drywise is a marked improvement in print quality, reducing the variation between different print jobs.

Decreased material waste

With more predictable and reliable printing conditions, there were fewer failed prints and thus, less material waste.

Material properties preservation

The continuous drying process helped preserve the mechanical properties of the filament, ensuring that the high performance of the rotor arm attachment component and the overall Auriol drones remained uncompromised.

"Integrating innovative materials from Fiberthree, paired with Drywise filament dryer into our production process has been a groundbreaking move. We have dramatically improved our printed parts quality and reliability while still leveraging the flexibility of in-house production. Further we’ve cut our drying times significantly, the quality of our prints has improved remarkably, and we’re seeing much less material waste. It’s truly revolutionizing the way we produce our Auriol drones." Benjamin Wiens, Co-founder of Third Element Aviation

Partners

Drywise

Thought3D, the creators of Magigoo and the innovative force behind Drywise, is a pioneering company dedicated to addressing and resolving the challenges associated with the drying of hygroscopic materials in the FDM 3D printing industry. Drywise, our flagship product, is a groundbreaking in-line filament drying solution, meticulously engineered to deliver consistent, reliable, and on-demand filament drying. Specifically designed for industrial desktop 3D printer users, Drywise ensures optimal print quality by maintaining the ideal moisture levels in printing materials, thereby revolutionizing the 3D printing process.

Third Element Aviation

Third Element Aviation is a leading company in the development and production of high-performance drones and applications for industrial process optimization. Based in Bielefeld, Germany, the company was established in 2017 by co-founders Marius Schröder and Benjamin Wiens. It has substantial experience in the drone application business, including business development, manufacturing, and selling commercial drone systems, as well as thousands of hours of piloting experience in various applications and scenarios worldwide. Focusing on highly automated, tailor-made drone solutions, the team has implemented drone solutions all around the world, from simple visual inspections, through fully automated logistics solutions all the way to integrating complex sensors.

Fiberthree

Fiberthree is a renowned innovator in the realm of 3D printing, hailing from Germany with a central emphasis on advanced materials. Established in 2015, the company has carved out a strong presence in the field of industrial applications, offering a wide array of filament products. Their offerings span an extensive spectrum of PA6- or PA12-based polyamides with different fibers, such as carbon- or glass-fibers. Together with new products like a PP-GF or PC-CF their portfolio offers industrial solutions for most technical challenges.

Pioneering in the arena of technical filaments, Fiberthree’s forte lies in the evolution of polyamide filaments. Among their cutting- edge products, the F3 PA-CF Pro filament holds a prominent place. Uniquely composed, this filament contains a 15% carbon fiber filler, aparable filaments. The inclusion of carbon fiber significantly curtails material shrinkage and amplifies both strength and stiffness and adherence to the print bed. A unique configuration reduces the likelihood of warping.