SLS Printing: Unlocking the Potential of Selective Laser Sintering

Breaking the Mold: How SLS Printing is Shaping the Future of Manufacturing with Unmatched Precision, Efficiency, and Creative Freedom

SLS printing

Introduction

Selective Laser Sintering (SLS) is a groundbreaking 3D printing technology that has revolutionized various industries, from aerospace and automotive to medical and consumer products. The core strength of SLS printing lies in its ability to create highly complex and functional parts with a wide range of materials, including polymers, metals, and ceramics. This article delves deep into the world of SLS printing, providing a comprehensive understanding of the technology, its materials, applications, and comparisons with other 3D printing processes. By the end of this article, you will have a solid grasp of the intricacies of SLS printing, its advantages, and the challenges it faces, along with insights into its future potential.

1. The Fundamentals of SLS Printing

In this section, we will explore the basics of Selective Laser Sintering (SLS) technology, beginning with its definition, the process, and the types of materials used in SLS printing. Understanding these fundamentals is essential for grasping the capabilities and limitations of SLS printing and how it compares to other 3D printing technologies.

1.1. What is Selective Laser Sintering (SLS)?

Selective Laser Sintering (SLS) is an additive manufacturing process that uses a high-powered laser to fuse powdered material layer by layer, creating a three-dimensional object. The process was first developed in the 1980s by Dr. Carl Deckard and Dr. Joe Beaman at the University of Texas at Austin. Over the years, SLS printing has evolved and matured, becoming a popular choice for producing complex and functional parts across various industries.

The core of the SLS process is the precise control of the laser, which selectively sinters the powdered material based on a digital design file. The laser's energy heats the powder particles just below their melting point, causing them to fuse together through a process called sintering. This method allows SLS printing to produce parts with intricate internal structures, undercuts, and overhangs that would be difficult or impossible to create using traditional manufacturing methods.

SLS printing is versatile in its choice of materials, as it can process a wide range of polymers, metals, and ceramics. The most commonly used polymer in SLS printing is Nylon (Polyamide), which offers a good balance of strength, flexibility, and chemical resistance. Metals used in SLS printing include aluminum, stainless steel, and titanium, while ceramics such as alumina and zirconia are also compatible with the technology. Each material presents unique advantages and challenges, which will be discussed in greater detail in the subsequent sections.

1.2. How SLS Printing Works

The SLS printing process consists of several key steps that allow for the creation of intricate three-dimensional objects from a digital design file. Here, we will delve into the details of each step, explaining their significance and the role of the laser in the process.

Design preparation: The first step in the SLS printing process is preparing the digital design file, typically in the form of an STL or OBJ file. This file contains the geometry and dimensional data of the object to be printed. It is crucial that the design file is optimized for the SLS process, taking into account factors such as wall thickness, support structures, and material shrinkage during the sintering process.

Powder preparation: The build chamber of the SLS printer is filled with the chosen powdered material. The powder is spread evenly across the build platform, creating a thin layer with a thickness ranging from 50 to 200 microns, depending on the material and printer specifications. The build chamber is typically heated to a temperature just below the material's melting point to ensure efficient sintering.

Laser sintering: The high-powered laser, guided by the digital design file, selectively sinters the powder particles in the first layer. The laser's energy raises the temperature of the powder particles, causing them to fuse together without fully melting. The scanning speed of the laser and its power output are carefully controlled to ensure optimal sintering and part quality. Typical laser power for SLS printing ranges from 10 to 100 watts, depending on the material and machine.

Layer-by-layer building: Once the first layer is sintered, the build platform lowers by one layer thickness, and a fresh layer of powder is spread over the previous layer. The laser then sinters the new layer, fusing it with the layer beneath. This process is repeated until the entire object is built, with each layer adhering to the one below. It is important to note that unsintered powder surrounding the part acts as a natural support, allowing for complex structures and overhangs without the need for additional support material.

Part removal and post-processing: After the printing process is complete, the part is left to cool inside the build chamber. Once cooled, the part is removed from the powder bed, and any excess powder is brushed away or removed using compressed air. The unsintered powder can often be recycled for future prints, reducing material waste. Post-processing steps may include bead blasting, polishing, or applying a protective coating to the part, depending on the application and desired surface finish.

Understanding the SLS printing process and the importance of each step is crucial for successfully creating complex and functional parts. The precise control of the laser and the unique layer-by-layer building process allow for the production of parts with exceptional geometric freedom, setting SLS printing apart from other additive manufacturing techniques.

2. SLS Printing Materials

The versatility of SLS printing is largely attributed to the wide range of materials that can be used in the process. In this section, we will explore the various types of materials commonly employed in SLS materials, including polymers, metals, and ceramics. We will discuss their properties, advantages, and limitations, as well as specific examples and applications of each material type.

2.1. Polymers

Polymers are the most commonly used materials in SLS printing due to their relatively low processing temperatures and ease of handling. These materials offer a diverse range of mechanical properties, making them suitable for a variety of applications. Some widely used polymers in SLS printing include:

Nylon (Polyamide): Nylon is a popular choice for SLS printing because of its excellent combination of strength, flexibility, and chemical resistance. It is available in several grades, such as PA 11, PA 12, and PA 6, each with its specific properties and applications. For example, PA 12 is known for its high fatigue resistance and dimensional stability, making it suitable for automotive and aerospace components. In contrast, PA 11 offers superior impact resistance and flexibility, making it ideal for producing sports equipment and living hinges, PA 6 is commonly used in the automotive industry for parts like car engine components due to its high mechanical strength and heat resistance. Additionally, it's also used for manufacturing consumer goods like kitchen utensils due to its excellent durability and food-safe properties.

Thermoplastic Polyurethane (TPU): TPU is a highly flexible and elastic material that is often used in SLS printing for creating parts that require excellent abrasion resistance and rebound properties. It is particularly well-suited for producing seals, gaskets, and protective cases for electronic devices. TPU also boasts excellent resistance to oils, greases, and various solvents, making it an ideal choice for components exposed to harsh chemical environments.

Polyetherketoneketone (PEKK): PEKK is a high-performance polymer that offers exceptional mechanical, thermal, and chemical properties. With a glass transition temperature of around 162°C and a melting temperature of approximately 372°C, PEKK can withstand high temperatures and maintain its structural integrity in demanding environments. Its excellent mechanical properties and chemical resistance make it suitable for aerospace, automotive, and oil and gas industry applications, such as gears, brackets, and engine components.

Polyetherimide (PEI): PEI, often marketed under the brand name ULTEM, is a high-performance polymer known for its excellent dimensional stability, high strength-to-weight ratio, and outstanding resistance to chemicals and high temperatures. With a glass transition temperature of approximately 217°C, PEI is suitable for applications that require long-term thermal stability, such as electrical insulators, medical devices, and aerospace components.

In laser sintering, the properties of resulting parts are influenced by the interplay between process parameters and the material. Particle geometry affects component coarseness and porosity. Higher powder density enhances part density, accuracy, and strength, but may hinder material flow. To overcome this, laser sintering powders with favorable flowability consist of narrow size distribution spherulite particles, typically around d = 60 μm.

The polymer must resist thermal degradation as it is exposed to high temperatures for extended periods. Non-molten, thermally degraded powder is separated from the sintered component for potential recycling. Ideally, the powder should not agglomerate, allowing for gravity-based separation. Aging during construction alters the powder's properties, requiring mixing with up to 50 wt.-% of fresh powder to maintain desired material properties and optimal performance in subsequent sintering operations.

Understanding the properties, advantages, and limitations of different polymers in SLS printing is essential for selecting the appropriate material for a specific application. By leveraging the unique characteristics of each polymer, designers and engineers can create parts that meet the requirements of their respective industries and applications.

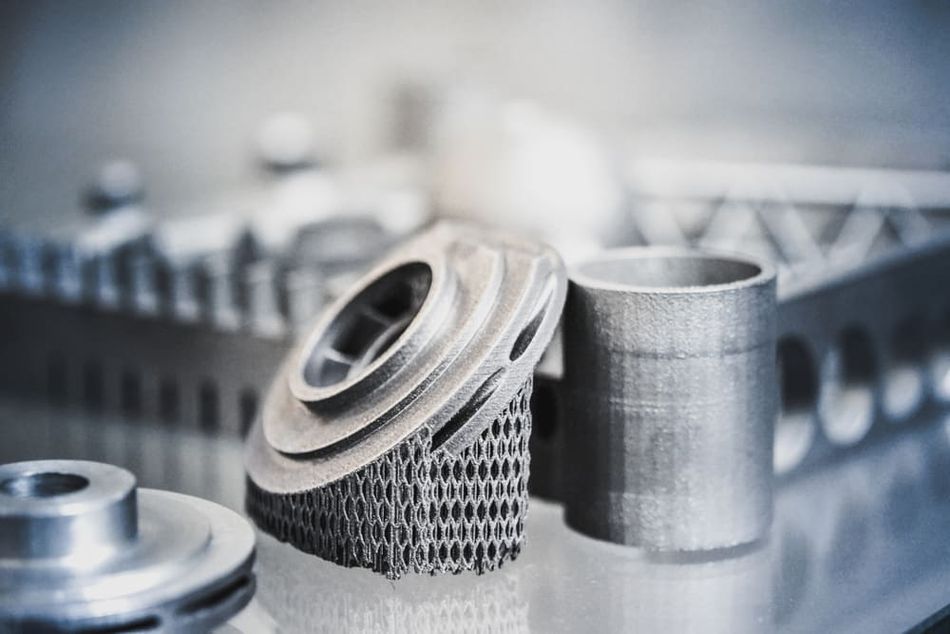

2.2. Metals

In recent years, the use of metals in SLS printing has expanded significantly, enabling the production of highly complex and durable parts for industries such as aerospace, automotive, and medical. Metal SLS printing, also known as selective laser melting (SLM) or direct metal laser sintering (DMLS), has opened up new possibilities for creating lightweight and high-strength components with intricate geometries that were previously impossible or cost-prohibitive using traditional manufacturing methods. The following paragraphs provide an overview of some common metals used in SLS printing and their specific properties and applications.

Aluminum: Aluminum is a lightweight metal with an excellent strength-to-weight ratio, making it a popular choice for SLS printing in aerospace and automotive applications. AlSi10Mg, an aluminum alloy containing silicon and magnesium, is often used due to its good mechanical properties, corrosion resistance, and thermal conductivity. SLS-printed aluminum parts can be employed in various applications, including engine components, heat exchangers, and lightweight structural parts.

Titanium: Titanium is known for its high strength, low density, and excellent corrosion resistance, making it an ideal material for SLS printing in aerospace, medical, and high-performance automotive applications. The most common titanium alloy used in SLS printing is Ti6Al4V, which combines the benefits of titanium with the added strength and heat resistance provided by aluminum and vanadium. Examples of SLS-printed titanium components include medical implants, such as hip and knee replacements, and aerospace components like turbine blades and structural parts.

Stainless Steel: Stainless steel is a versatile and robust material that offers a unique combination of strength, corrosion resistance, and wear resistance. In SLS printing, stainless steel alloys such as 316L and 17-4 PH are commonly used due to their excellent mechanical properties and suitability for a wide range of applications. SLS-printed stainless steel parts can be found in industries like automotive, oil and gas, and consumer products, and are commonly used for components like valves, gears, and housings.

Cobalt-Chromium: Cobalt-chromium alloys are characterized by their high strength, wear resistance, and biocompatibility, making them an attractive choice for SLS printing in medical and dental applications. One popular cobalt-chromium alloy for SLS printing is CoCrMo, which exhibits excellent mechanical properties and corrosion resistance. SLS-printed cobalt-chromium components are often used in dental prosthetics, such as crowns and bridges, as well as orthopedic implants like knee and hip replacements.

The process of selecting the most suitable metal for an SLS printing project hinges upon discerning the specific requirements of the application, encompassing factors such as strength, weight, corrosion resistance, and biocompatibility. By comprehending the inherent properties and advantages inherent in different metals, engineers and designers are empowered to make well-informed decisions, enabling them to fabricate high-performance components that effectively meet the rigorous demands of their respective industries.

2.3. Ceramics

Ceramics are an emerging class of materials for SLS printing due to their unique properties, such as high temperature resistance, hardness, and biocompatibility. SLS-printed ceramics find applications in industries like aerospace, electronics, and medical devices. This section delves into the characteristics of ceramics used in SLS printing and explores some of their specific applications.

Alumina (Al2O3): Alumina, also known as aluminum oxide, is a widely used ceramic material in SLS printing due to its exceptional hardness, wear resistance, and electrical insulating properties. With a melting point of approximately 2,072°C (3,762°F), alumina is suitable for high-temperature applications such as engine components and electrical insulators. In addition, its excellent biocompatibility makes it an ideal choice for medical and dental implants.

Zirconia (ZrO2): Zirconia, or zirconium dioxide, is another ceramic material commonly used in SLS printing. Known for its high strength, fracture toughness, and resistance to wear and corrosion, zirconia is often utilized in applications requiring high mechanical performance. Its biocompatibility and aesthetics make it a popular choice for dental restorations, such as crowns and bridges. In addition, zirconia's low thermal conductivity and high temperature stability make it suitable for high-temperature applications like thermal barrier coatings in gas turbine engines.

Silicon Carbide (SiC): Silicon carbide is a ceramic material with excellent thermal and mechanical properties, making it suitable for SLS printing in applications requiring high strength and temperature resistance. Its high thermal conductivity and low thermal expansion coefficient make it an attractive choice for heat exchangers, combustion chambers, and other high-temperature applications. In addition, SiC's hardness and wear resistance make it suitable for components such as bearings, seals, and cutting tools.

Hydroxyapatite (HA): Hydroxyapatite is a bioceramic material that closely resembles the mineral component of human bone, making it an ideal choice for SLS printing in medical applications. Due to its biocompatibility and ability to promote bone growth and tissue integration, hydroxyapatite is frequently used for bone implants, such as spinal fusion devices and cranial plates. Moreover, it can be combined with other materials like polymers to create composite structures with tailored properties.

SLS printing with ceramics offers several advantages over traditional manufacturing methods, including the ability to create complex geometries, reduced material waste, and the potential for customization. By understanding the specific properties and applications of various ceramic materials, designers and engineers can take full advantage of the capabilities of SLS printing to develop innovative solutions across a range of industries.

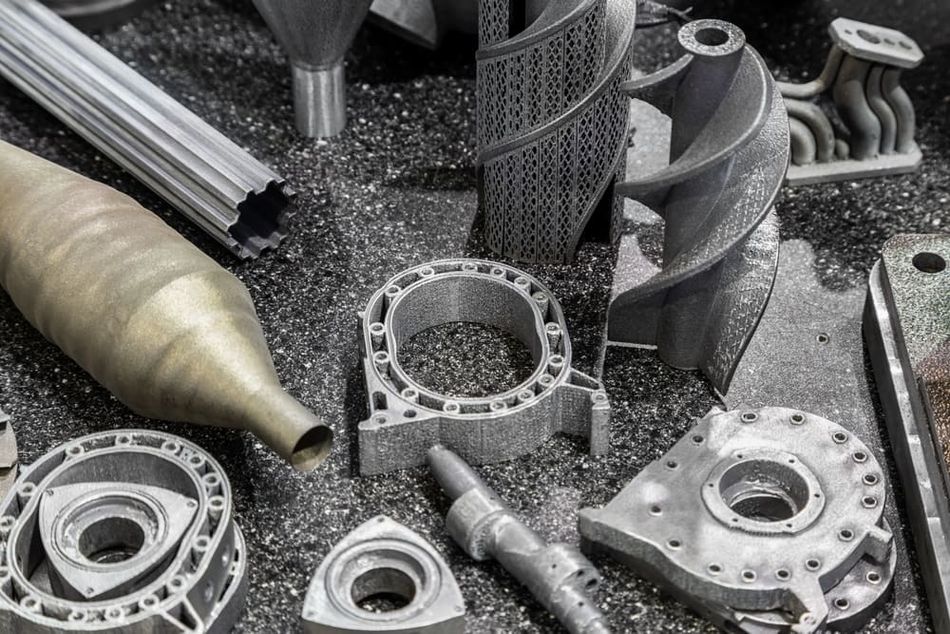

3. SLS Printing Applications

Selective Laser Sintering (SLS) has found widespread use in various industries due to its ability to create complex, high-strength parts with minimal material waste. This section will explore some of the most prominent applications of SLS printing across different industries, starting with aerospace.

3.1. Aerospace

The aerospace industry has embraced SLS printing as a valuable tool for creating lightweight, high-performance components. The ability to create complex structures with reduced weight and improved performance has led to the development of various aerospace components using SLS printing technology.

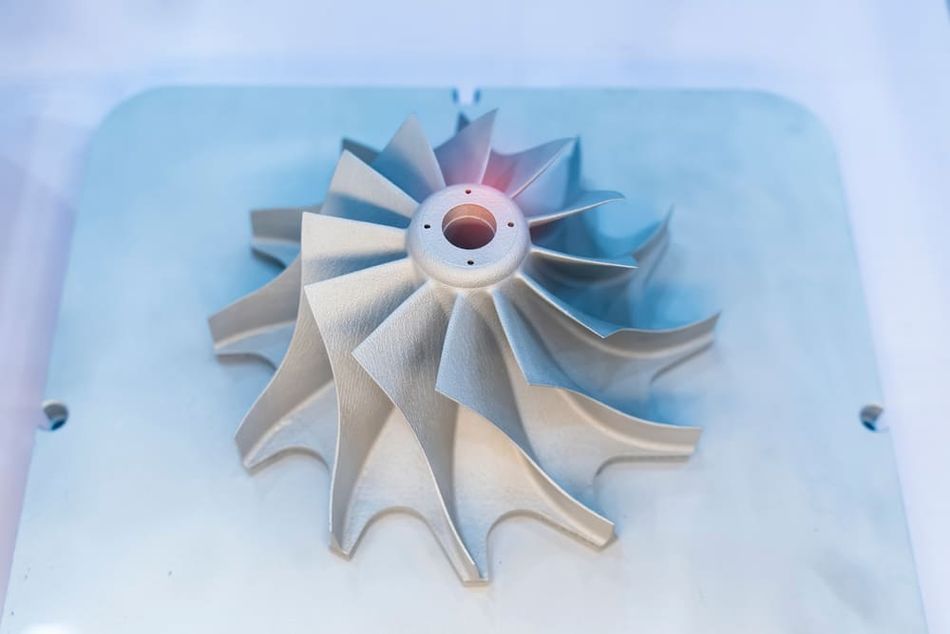

Engine components: SLS printing enables the production of intricate, lightweight engine parts that can withstand high temperatures and stresses. For example, components like combustion chambers and turbine blades can be manufactured with internal cooling channels to improve thermal performance. These channels would be challenging, if not impossible, to create using traditional manufacturing methods. Furthermore, using metal powders like titanium and Inconel ensures that the printed parts have high strength and temperature resistance.

Structural components: The aerospace industry demands lightweight, strong components to improve fuel efficiency and overall performance. SLS printing allows engineers to design and manufacture structural components with optimized geometries and material distribution, resulting in weight savings without sacrificing strength. For instance, lattice structures can be printed to replace solid parts, reducing weight while maintaining structural integrity.

Customized interior components: SLS printing enables the production of customized interior components for aircraft cabins, such as seat frames and paneling. By optimizing the design for weight reduction and printing using high-performance polymers, manufacturers can achieve significant weight savings and improved passenger comfort. Furthermore, SLS printing allows for the creation of intricate patterns and textures, enhancing the aesthetics of the cabin.

Tooling and fixtures: In addition to manufacturing end-use components, SLS printing is also used to create custom tooling and fixtures for aerospace production lines. These tools can be designed to fit the specific contours of a component, resulting in improved precision and reduced production time. Moreover, SLS-printed tools are often lighter than their traditionally manufactured counterparts, making them easier to handle and reducing worker fatigue.

The adoption of SLS printing in the aerospace industry has led to significant advancements in terms of weight reduction, fuel efficiency, and overall performance. By leveraging the unique capabilities of this technology, aerospace manufacturers can continue to push the boundaries of what is possible in aircraft design and production.

3.2. Automotive

SLS printing has made a significant impact in the automotive industry, enabling the production of complex, lightweight, and high-performance components. The technology has revolutionized various aspects of automotive manufacturing, including prototyping, production of end-use parts, and tooling. Here, we explore some specific applications of SLS printing within the automotive sector.

Rapid prototyping: The ability to quickly and cost-effectively produce prototypes is essential for the automotive industry. SLS printing allows engineers to create functional prototypes in a matter of hours, significantly reducing the time and cost associated with traditional prototyping methods. This enables manufacturers to iterate on designs faster and more effectively, ultimately accelerating product development cycles.

End-use parts: SLS printing is not limited to prototyping and has found use in the production of end-use parts for both standard and high-performance vehicles. The technology enables the creation of lightweight, intricate components that can reduce overall vehicle weight and improve fuel efficiency. For example, SLS printing can be used to create intake manifolds with optimized geometries, resulting in improved airflow and engine performance. Moreover, the use of high-performance polymers and metals in SLS printing ensures that the printed parts can withstand the demanding conditions of automotive applications.

Customization: The automotive industry has witnessed a growing demand for personalization and customization. SLS printing allows manufacturers to create bespoke components tailored to individual customer preferences without the need for costly tooling changes. This can include unique interior trim pieces, custom grilles, and even personalized brake calipers. The flexibility of SLS printing enables manufacturers to offer a wide range of customization options while maintaining cost efficiency.

Tooling and fixtures: SLS printing has also found use in the creation of tooling and fixtures for automotive assembly lines. These tools can be custom designed for specific applications, resulting in increased precision and reduced production times. Additionally, SLS-printed tools are often lighter than those made using traditional manufacturing methods, making them easier to handle and reducing worker fatigue.

Motorsports: The high-performance demands of motorsports have driven the adoption of SLS printing for various applications. In this domain, SLS printing is used to produce lightweight, high-strength components that can withstand extreme stresses and temperatures. For example, SLS-printed titanium parts have been used in Formula 1 racing, where weight reduction and performance are critical factors.

The automotive industry has greatly benefited from the adoption of SLS printing, enabling the rapid production of prototypes, end-use parts, and tooling. The technology's ability to create complex, lightweight components has led to improvements in vehicle performance, efficiency, and customization, making it an indispensable tool for automotive manufacturers.

3.3. Medical and Dental

Selective laser sintering has made significant contributions to the medical and dental industries, revolutionizing the way devices and implants are designed and manufactured. SLS printing has enabled the creation of intricate, patient-specific components that enhance the precision and effectiveness of treatments, as well as improving patient outcomes. Here, we explore some specific applications of SLS printing within the medical and dental sectors.

Orthopedic implants: SLS printing has allowed for the production of patient-specific orthopedic implants, such as hip and knee replacements. By using CT or MRI scans, implants can be tailored to the patient's unique anatomy, resulting in a better fit and improved functionality. Additionally, SLS printing can create porous structures that promote bone ingrowth, leading to a stronger bond between the implant and the patient's bone.

Surgical guides and models: Surgeons often rely on accurate anatomical models to plan complex procedures. SLS printing enables the creation of patient-specific models using medical imaging data, providing an invaluable tool for preoperative planning. Moreover, SLS-printed surgical guides can be used during procedures to improve accuracy and reduce the risk of complications, ultimately leading to better patient outcomes.

Dental applications: The dental industry has also seen numerous advances due to SLS printing. For example, the technology can be used to create custom dental crowns, bridges, and orthodontic appliances, all tailored to the individual patient's oral anatomy. These custom-fitted devices offer improved comfort and functionality compared to traditional, mass-produced alternatives.

Prosthetics: SLS printing has revolutionized the field of prosthetics by allowing for the creation of lightweight, customized devices that can be tailored to each patient's unique needs. The technology can produce complex geometries and lattice structures, reducing the weight of the prosthetic while maintaining strength and durability. Additionally, SLS-printed prosthetics can be easily adjusted or modified to accommodate changes in the patient's condition, such as growth or weight loss.

Bioprinting: While still in the early stages of development, bioprinting using SLS technology has the potential to create tissue scaffolds and even complete organs using living cells. By printing cellular structures layer by layer, researchers aim to build functional tissues that can be used for transplantation or drug testing. This area of research holds great promise for the future of regenerative medicine and personalized treatments.

SLS printing has had a profound impact on the medical and dental industries, enabling the production of patient-specific devices, implants, and models that improve the precision and effectiveness of treatments. The technology's ability to create complex, tailored components has led to advances in orthopedics, surgery, dentistry, prosthetics, and bioprinting, making it an invaluable tool for medical professionals and researchers alike.

3.4. Consumer Products

Selective laser sintering (SLS) has a significant impact on the consumer products industry, offering new possibilities for the design, prototyping, and manufacturing of various items. The versatility of SLS printing has led to its adoption across a wide range of consumer goods, from eyewear to footwear and electronics. In this section, we delve into specific applications of SLS printing in the consumer products sector.

Eyewear: SLS printing has revolutionized the eyewear industry by enabling the creation of lightweight, durable, and highly customizable frames. Designers can easily experiment with complex geometries and lattice structures, resulting in unique and innovative designs that can be tailored to individual preferences. The use of nylon materials in SLS printing also provides excellent flexibility and strength, ensuring a comfortable fit and long-lasting performance.

Footwear: The footwear industry has also benefited from the capabilities of SLS printing. Shoe manufacturers can use this technology to create midsoles with intricate lattice structures, which provide optimal cushioning, support, and breathability. Furthermore, SLS printing allows for the production of customized shoe components, such as insoles or heel cups, tailored to the wearer's unique foot shape and biomechanics.

Electronics: SLS printing has found applications in the electronics industry as well, primarily in the development of custom enclosures and housings for devices like smartphones, tablets, and wearables. By using SLS printing, designers can create complex geometries and incorporate features like built-in cable management, ventilation, or mounting points. The technology also enables rapid prototyping and iteration, allowing for faster product development cycles and quicker time-to-market.

Sporting goods: SLS printing has also been employed in the design and production of various sporting goods, such as bike components, golf clubs, and protective gear. The technology's ability to produce lightweight, strong, and intricate structures makes it well-suited for creating high-performance equipment that caters to the specific needs of athletes and recreational users alike.

Customized products: One of the most notable benefits of SLS printing is its ability to create personalized items tailored to individual consumers. The technology allows for the creation of products with unique features or designs, such as phone cases with intricate patterns, jewelry with bespoke detailing, or household items with specific functionality. SLS printing has opened up new possibilities for mass customization, giving consumers the opportunity to own truly one-of-a-kind products.

The adoption of SLS printing in the consumer products industry has led to a range of innovative applications, from eyewear and footwear to electronics and sporting goods. Its ability to produce complex, lightweight, and durable components has made it an invaluable tool for product designers and manufacturers, driving the development of unique and personalized items that cater to the evolving needs and preferences of consumers.

4. SLS Printing vs. Other 3D Printing Technologies

Selective laser sintering (SLS) is one of the many additive manufacturing techniques available today. To better understand its capabilities and limitations, it is essential to compare it to other popular 3D printing technologies. In this section, we will discuss SLS printing in relation to fused deposition modeling (FDM) and stereolithography (SLA).

4.1. SLS vs. FDM

Selective laser sintering (SLS) and fused deposition modeling (FDM) are both widely used 3D printing technologies, but they differ significantly in their working principles, material options, and application areas.

Working principles: SLS uses a high-power laser to selectively fuse powdered material layers, while FDM works by extruding molten thermoplastic material layer by layer onto a build platform. Due to the differences in the working principles, SLS and FDM parts exhibit different mechanical properties and surface finishes.

Mechanical properties: SLS-printed parts are generally stronger and more isotropic than those produced using FDM. This is because the laser sintering process results in a more consistent material structure, which leads to improved strength and uniform properties in all directions. FDM parts, on the other hand, can exhibit weaker layer adhesion and anisotropic properties due to the nature of the extrusion process.

Surface finish: SLS parts generally have a rougher surface finish than FDM parts, with a grainy texture resulting from the sintered powder particles. FDM parts, on the other hand, can have a smoother surface finish, though they often exhibit visible layer lines. Post-processing techniques, such as sanding or polishing, can be used to improve the surface finish of both SLS and FDM parts.

Material options: SLS offers a wider range of material options, including polymers, metals, and ceramics, while FDM is primarily limited to thermoplastics. This makes SLS a more versatile technology for various industries and applications. However, FDM's material palette has been expanding over the years, with the introduction of composite filaments that incorporate materials like carbon fiber, metal, or wood particles.

Support structures: SLS does not require support structures, as the unsintered powder surrounding the part provides the necessary support during the build process. This allows for greater design freedom and the ability to produce complex, interlocking parts without the need for post-processing to remove supports. FDM, however, typically requires support structures for overhangs and intricate geometries, which can increase the print time and post-processing effort.

Cost and accessibility: FDM printers are generally more affordable and accessible to a broader audience, making them popular choices for hobbyists, educational institutions, and small businesses. SLS printers, on the other hand, are often more expensive and require specialized equipment and facilities to handle the powdered materials and post-processing steps.

SLS and FDM have distinct advantages and drawbacks, making them suitable for different applications and industries. SLS excels in producing strong, complex parts with a wide range of material options, while FDM offers affordability and accessibility, making it a popular choice for rapid prototyping and smaller-scale production.

4.2. SLS vs. SLA

Selective laser sintering (SLS) and stereolithography (SLA) are both advanced 3D printing technologies that cater to different applications and industries. In this section, we will explore the differences between SLS and SLA, considering factors such as working principles, material options, surface finish, and accuracy.

Working principles: SLS and SLA use different methods to create 3D objects. SLS employs a high-power laser to sinter powdered materials layer by layer, whereas SLA relies on a light source (usually a laser or a projector) to selectively cure liquid photopolymer resins. The distinct working principles of these technologies result in variations in part properties and surface finishes.

Material options: SLS offers a broad range of materials, including polymers, metals, and ceramics. SLA primarily works with photopolymer resins, which are available in various formulations to cater to different requirements, such as high strength, flexibility, or transparency. However, SLA materials are generally more limited in comparison to the variety of materials available for SLS.

Surface finish: SLA is known for its superior surface finish, with smooth surfaces and fine details that often require minimal post-processing. SLS parts, on the other hand, have a grainy, rough surface finish due to the sintered powder particles. While post-processing techniques can improve the surface quality of SLS parts, they generally cannot achieve the same level of smoothness as SLA parts.

Accuracy and resolution: SLA is capable of producing parts with high accuracy and resolution, thanks to the precise light source and fine control over the curing process. The minimum layer thickness in SLA can be as low as 25 microns, enabling the production of intricate features and sharp edges. SLS machine, while still accurate, typically has a higher minimum layer thickness, around 50-100 microns. This may result in slightly lower resolution and less sharp edges compared to SLA parts. Due to high accuracy the parts snap fits for both SLS and SLA.

Support structures: SLS does not require support structures, as the unsintered powder provides support during the build process. This allows for greater design freedom and complex geometries without the need for post-processing to remove supports. SLA, however, requires support structures for overhangs and intricate features. While these supports can be removed after printing, they may leave marks on the surface that require additional post-processing to achieve a smooth finish.

Mechanical properties: SLS parts are generally more robust and have better isotropic properties compared to SLA parts. The sintering process results in a consistent material structure, leading to improved strength and uniform properties in all directions. SLA parts, while strong, can be more brittle and susceptible to degradation over time due to exposure to UV light, humidity, and temperature changes.

SLS and SLA 3D printing technologies cater to different applications based on their respective strengths and weaknesses. SLS is well-suited for producing strong, functional parts with a variety of material options, while SLA excels in creating highly detailed and smooth parts with high accuracy and resolution.

Suggested read: 3D printing technology: SLA vs SLS

4.3. SLS vs. DMLS

Selective laser sintering (SLS) and direct metal laser sintering (DMLS) are both 3D printing technologies that create parts layer by layer using a laser. While they share similarities, they have distinct differences in terms of materials, applications, and process characteristics. This section will delve into these differences, examining the working principles, material options, surface finish, accuracy, and mechanical properties of SLS and DMLS.

Working principles: SLS utilizes a high-power laser to sinter powdered materials such as polymers, metals, and ceramics, solidifying the material layer by layer. DMLS, on the other hand, is a specific subset of SLS that focuses exclusively on metal powders. In DMLS, a high-powered laser selectively melts the metal powder, creating a dense, solid part as the layers fuse together. The key difference between the two 3D printing processes is the way the material is bonded: SLS sinters the powder, while DMLS fully melts it.

Material options: SLS is compatible with a wide range of materials, including various polymers, metals, and ceramics. DMLS, however, is limited to metal powders, such as stainless steel, titanium, aluminum, and Inconel. The narrower material selection for DMLS is offset by the fact that it can create parts with properties similar to those produced using traditional metalworking techniques.

Surface finish: SLS parts typically have a rough surface finish due to the sintering process and the nature of the powdered materials. This may require post-processing to achieve a smoother surface or meet specific dimensional requirements. DMLS parts also exhibit a rough surface finish, which can be attributed to the layer-by-layer melting and solidification process. DMLS parts often require post-processing, such as polishing or machining, to achieve a smoother surface and tighter tolerances.

Accuracy and resolution: Both SLS and DMLS are capable of producing accurate parts with good resolution. SLS typically has a minimum layer thickness of 50-100 microns, while DMLS can achieve layer thicknesses as low as 20-50 microns. The finer resolution offered by DMLS allows for the creation of intricate features and complex geometries in metal parts.

Mechanical properties: SLS parts exhibit good mechanical properties and isotropy due to the consistent material structure created by the sintering process. DMLS parts, however, have mechanical properties that can be superior to those produced by SLS, particularly in terms of density and strength. The full melting and solidification process in DMLS results in parts with a dense, uniform microstructure, which translates to improved mechanical performance.

Applications: SLS is well-suited for producing functional prototypes, low-volume production parts, and complex geometries across a wide range of industries, including aerospace, automotive, and medical. DMLS, with its focus on metal materials, is particularly useful for applications that require high-strength, durable parts, such as aerospace components, medical implants, and customized tooling.

SLS and DMLS are both valuable 3D printing technologies with their own strengths and limitations. SLS offers a broader range of materials and versatility, making it suitable for various industries and applications. DMLS, on the other hand, focuses on metal materials, providing an opportunity to create high-performance parts with properties similar to those of traditionally manufactured metal components.

5. Advantages of SLS Printing

Selective laser sintering (SLS) is a popular 3D printing technology due to its numerous advantages. This section will explore several benefits of SLS printing, including design freedom, functional parts production, material options, and cost-effectiveness.

5.1. Design Freedom

One of the primary advantages of SLS printing is the design freedom it offers. The technology allows for the creation of complex geometries, internal structures, and intricate details that would be difficult or impossible to achieve with traditional manufacturing methods. This is possible because the process uses a high-power laser to sinter powdered materials layer by layer, which eliminates the need for support structures during printing.

SLS enables designers and engineers to create parts with features such as undercuts, interlocking components, and lattice structures without additional tooling or assembly. These capabilities open up new possibilities for lightweight and optimized designs, as well as enhanced functional performance.

This design freedom is particularly beneficial in industries such as aerospace, automotive, and medical, where weight reduction and part complexity are critical factors. SLS-printed parts can improve fuel efficiency in aerospace and automotive applications or reduce the weight of orthopedic implants, improving patient outcomes in the medical field.

Furthermore, SLS allows for the efficient production of custom or one-off parts, enabling rapid design iterations and customization for specific applications. This capability is invaluable in industries where tailored solutions are necessary, such as prosthetics or dental restoration.

5.2. Material Properties

Selective laser sintering (SLS) is known for producing parts with excellent material properties. This advantage stems from the process's ability to create strong and durable components, as well as its compatibility with a wide range of materials.

SLS-printed parts exhibit high strength and durability due to the sintering process, which involves using a laser to fuse the powdered material layer by layer. This fusion creates strong bonds between the particles, resulting in a homogeneous and isotropic structure. As a consequence, SLS parts often have mechanical properties that are comparable or even superior to those created by traditional manufacturing methods, such as injection molding.

The strength and durability of SLS parts can be further enhanced through post-processing techniques, such as infiltration with a secondary material or heat treatment. For example, infiltrating a nylon SLS part with a low-viscosity epoxy resin can improve its tensile strength by up to 50% and its elongation at break by 40%.

In addition to producing strong and durable components, SLS is compatible with a broad range of materials, including polymers, metals, and ceramics. This versatility enables the technology to cater to various industries and applications, each with their specific material requirements. For instance, the aerospace industry can benefit from lightweight, high-performance polymers, while the automotive industry can utilize metal alloys for robust and wear-resistant parts.

SLS technology's ability to process specialized materials, such as biocompatible polymers, also makes it suitable for medical and dental applications. Biocompatible materials, like polyetherketoneketone (PEKK) and polyetheretherketone (PEEK), can be used to create patient-specific implants and prosthetics that exhibit excellent mechanical properties and biological compatibility.

The material properties of SLS-printed parts, combined with the wide range of compatible materials, make the technology highly attractive for producing strong, durable, and functional components for various industries and applications.

5.3. Rapid Prototyping and Production

Selective laser sintering (SLS) technology is particularly advantageous for rapid prototyping and production applications. The speed and efficiency of the SLS process, combined with its ability to produce complex geometries, make it an ideal choice for various industries seeking to accelerate the product development cycle and reduce lead times.

One of the main benefits of SLS for rapid prototyping is its ability to quickly create functional prototypes. Unlike other 3D printing methods that may require support structures, SLS parts are self-supporting due to the unsintered powder surrounding the printed part. This feature allows for faster design iterations and a reduction in post-processing steps, ultimately enabling companies to bring their products to market more quickly.

Moreover, the freedom of design offered by SLS enables the creation of complex geometries that are difficult or impossible to achieve through traditional manufacturing methods. This capability allows designers and engineers to explore new design possibilities and optimize the performance of their products. As a result, SLS technology can contribute to reducing material waste, improving energy efficiency, and enhancing product functionality.

In addition to rapid prototyping, SLS is well-suited for low-to-medium volume production. The technology's scalability, combined with its compatibility with a wide range of materials, allows manufacturers to produce parts that are tailored to specific applications and industries. For instance, the automotive and aerospace sectors can benefit from lightweight, high-performance components, while the medical and dental industries can leverage biocompatible materials to produce patient-specific implants and devices.

SLS technology's suitability for production is further enhanced by its ability to create multiple parts simultaneously within the same print bed. This feature results in time and cost savings, as well as increased efficiency when producing small batches of components. As the demand for customized products and on-demand manufacturing continues to grow, SLS is poised to play a significant role in meeting these needs.

The rapid prototyping and production capabilities of SLS technology make it a valuable asset for companies seeking to accelerate product development, optimize designs, and efficiently produce customized components across various industries.

6. Challenges and Limitations of SLS Printing

Although selective laser sintering (SLS) technology offers numerous advantages, there are certain challenges and limitations that users must consider. These factors can affect the overall efficiency, cost, and quality of the final product. Understanding these challenges can help users make informed decisions when selecting the appropriate 3D printing method for their specific needs.

6.1. Post-Processing

One of the primary challenges associated with SLS printing is the post-processing required after the parts are printed. While the process doesn't typically require support structures, the parts are embedded in unsintered powder within the print bed. This powder needs to be removed, which can be a time-consuming and labor-intensive process. Additionally, this unsintered powder cannot be reused indefinitely, as it may degrade over time, resulting in increased material costs.

Furthermore, SLS printed parts often have a rough surface finish, which may not be suitable for certain applications. In cases where a smoother finish is required, additional post-processing steps, such as sanding or polishing, may be necessary. These extra steps can increase the overall production time and cost.

Another aspect of post-processing is the requirement for heat treatment, particularly for metal SLS parts. These parts may experience residual stress during the printing process, leading to potential warping or distortion. Heat treatment can alleviate these stresses, but it adds another step to the production process and can increase costs.

6.2. Material Limitations

Selective laser sintering technology, while versatile, faces certain material limitations that can impact its applicability across various industries. These limitations often stem from the sintering process itself and the range of materials that can be effectively processed using this method.

The sintering process requires materials with a specific set of properties, such as an appropriate melting point, thermal stability, and the ability to fuse together without excessive warping or distortion. As a result, the range of materials available for SLS printing is narrower compared to other 3D printing technologies, like FDM or SLA. While SLS is compatible with a variety of thermoplastic polymers, metals, and ceramics, there are still many materials that cannot be processed using this method.

Additionally, the material selection for SLS printing may be further restricted by the need for powder form. Converting some materials into fine, uniform powders can be challenging and expensive, which can limit the range of options available for SLS users. The quality and size distribution of the powder particles also play a critical role in the final part quality, further constraining the selection process.

Another limitation associated with material usage in SLS printing is the potential for material degradation during the sintering process. High temperatures can cause the breakdown of certain materials or alter their properties, resulting in parts that do not meet the desired specifications. This issue can be particularly prominent when dealing with temperature-sensitive or chemically unstable materials.

Two significant challenges arise for printing ceramics with SLS: high shrinkage and the presence of substantial porosity in the final parts. However, innovative techniques are emerging to tackle these issues head-on.

One such approach involves utilizing submicron alumina composite microspheres coated with polyamide-12 (PA12), a material known for its softening point of around 125°C. By employing a phase inversion process during the SLS, engineers have achieved composite microspheres with excellent flow characteristics. This breakthrough ensures smooth and efficient handling throughout the SLS process.

Despite these advancements, achieving optimal density in the final parts remains a persistent challenge. The low powder bed density caused by intersphere space persists throughout the steps of powder spreading, laser sintering, and final firing. As a result, the sintered density of the produced parts often falls short, reaching less than 50% of the theoretical density.

The recycling and reuse of unsintered powder from the build chamber can be a challenge. While some of the unused powder can be reused in subsequent builds, the process can lead to changes in the powder properties, such as particle size distribution and flowability. This can affect the quality of subsequent prints, and a balance must be struck between powder reuse and the introduction of fresh material to maintain consistent part quality.

6.3. Size Constraints

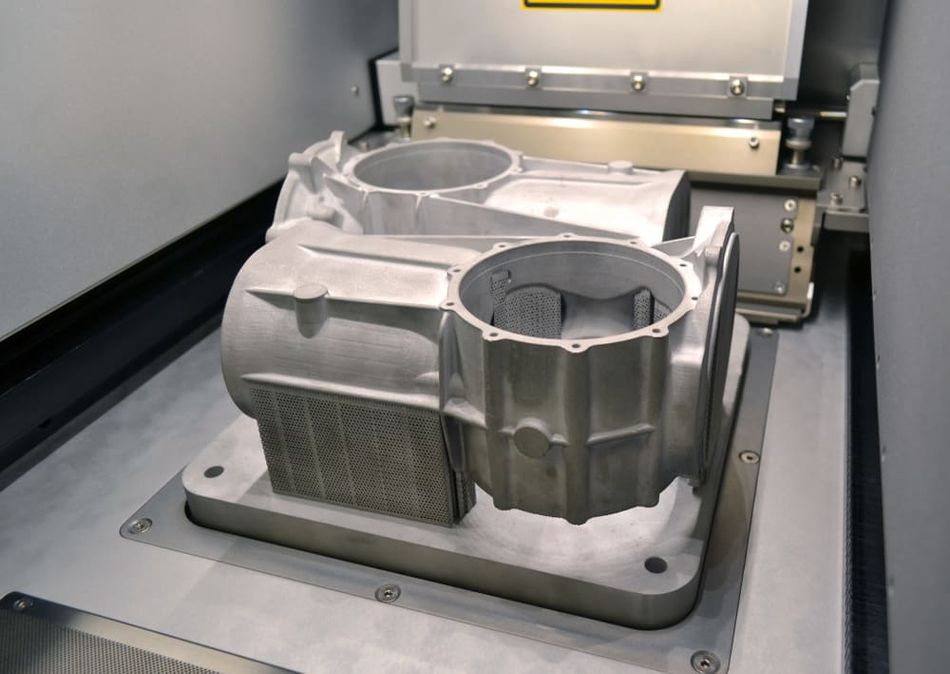

Size constraints in selective laser sintering (SLS) technology can limit its applicability in certain situations, as both minimum and maximum part dimensions may present challenges. These constraints are largely driven by the build volume of the SLS printer, as well as the characteristics of the sintering process and the materials being used.

Minimum part dimensions are influenced by factors such as the laser spot size, which determines the minimum feature size that can be accurately reproduced during the sintering process. Typically, the laser spot size in SLS printers ranges from 50 to 200 micrometers, depending on the printer model and settings. This imposes a lower limit on the size of the features that can be accurately printed, as smaller details may not be properly resolved or may experience warping or distortion due to the heat involved in the sintering process.

On the other hand, maximum part dimensions are primarily dictated by the build volume of the SLS printer. The build volume represents the maximum size that a part can occupy within the printer's chamber. While industrial SLS printers can offer build volumes of up to 1000 x 1000 x 1000 millimeters or larger, smaller desktop models may have significantly smaller build volumes, potentially limiting the types of projects that can be undertaken with these machines.

Large parts printed with SLS technology can also face challenges related to thermal stress and warping. The sintering process relies on the precise control of temperature and heat distribution, which can become increasingly difficult as part dimensions increase. Large parts may require more support structures to minimize warping, which can in turn increase the amount of post-processing required, affecting overall production efficiency.

The time required to complete an SLS print is directly related to the part's size and complexity. Larger parts take longer to print, which can impact production timelines and resource allocation. In some cases, it may be more efficient to divide a large part into smaller components, print them separately, and assemble them afterward, though this may introduce additional challenges related to assembly, material compatibility, and part strength.

Conclusion

Selective laser sintering (SLS) is a versatile and powerful additive manufacturing technology that has made significant strides in recent years. The process uses a high-power laser to fuse powdered materials layer by layer, enabling the creation of complex and detailed parts. SLS technology has numerous advantages, including design freedom, excellent material properties, and the ability to rapidly prototype and produce parts.

However, SLS printing is not without challenges and limitations. Post-processing, material limitations, and size constraints can affect the technology's applicability and effectiveness in certain scenarios. Despite these challenges, the technology has proven to be a valuable asset in various industries, such as aerospace, automotive, and medical sectors.

As SLS technology continues to evolve, it will likely become more accessible and user-friendly, with improvements in material selection, build volume, and post-processing techniques. It will further expand its range of applications and solidify its position as a key player in the world of additive manufacturing.

Frequently Asked Questions (FAQs)

What materials can be used in SLS printing?

SLS printing is compatible with a wide range of materials, including polymers, metals, and ceramics. Commonly used polymers include nylon (PA), polyamide 12 (PA12), and polypropylene (PP). Metals used in SLS include stainless steel, aluminum, and titanium. Ceramics, such as alumina and zirconia, can also be processed using SLS technology.

Can SLS printers create hollow parts or structures?

Yes, SLS printers can create hollow parts or structures, as they have the ability to print complex geometries without the need for support structures. This design freedom allows for the creation of lightweight and efficient parts, which can be especially beneficial in industries like aerospace and automotive.

How does SLS technology compare to other additive manufacturing methods, like SLA and DMLS?

SLS technology offers several advantages over other additive manufacturing methods like SLA and DMLS. Compared to SLA, which uses a liquid resin that is cured by a laser or light source, SLS offers improved mechanical properties and material options. While DMLS also uses a laser to fuse powdered materials, it is specifically designed for metal printing, whereas SLS can process a wider range of materials, including polymers and ceramics.

What are some common applications for SLS printing?

SLS printing is used in a variety of industries and applications, including aerospace, automotive, medical, and consumer products. Examples of SLS-printed parts include lightweight structures, complex geometries, and functional prototypes. SLS technology can also be used to create custom, patient-specific medical devices and implants.

References: