Small Wind Turbines for sustainable livelihoods

Distributed generation has the potential to take electricity to the most remote locations of the planet. By establishing an off-grid windmill and a battery management system, it becomes possible to collect and utilise electrical power sustainability as and when required.

This article is a part of our University Technology Exposure Program. The program aims to recognize and reward innovation from engineering students and researchers across the globe.

The technology

Design and material

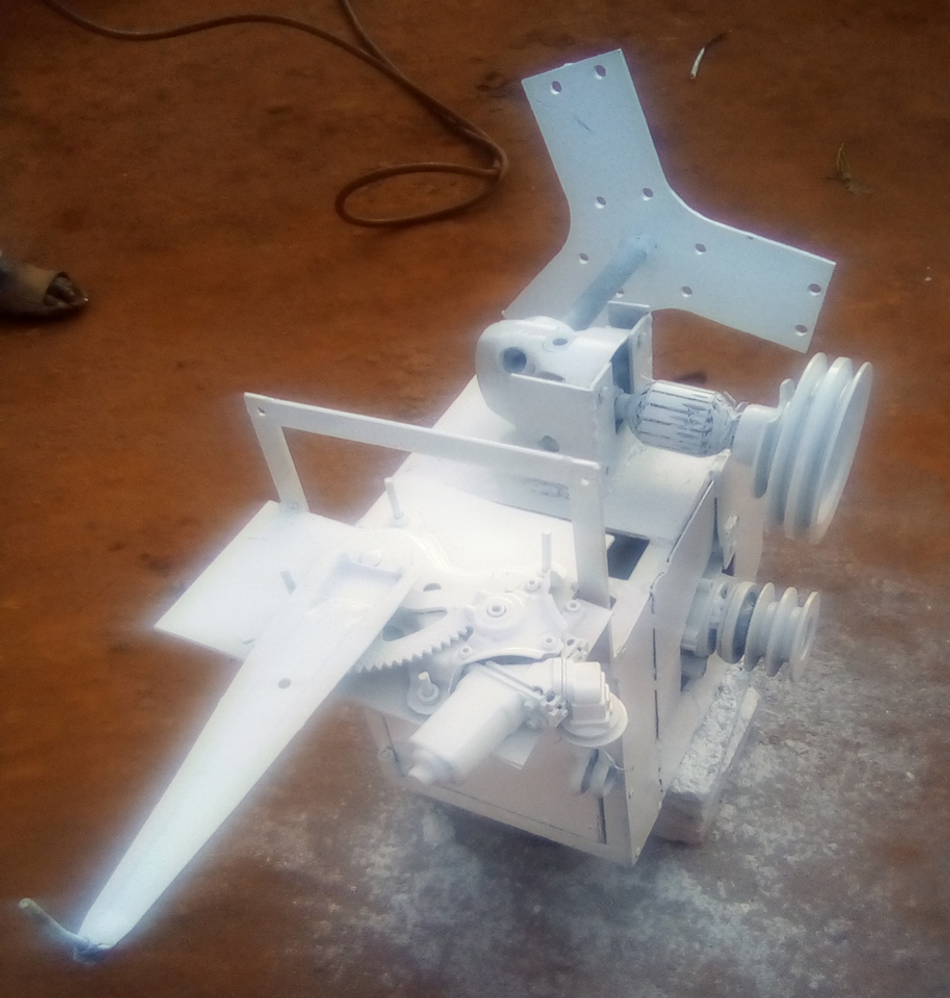

We built small wind turbines from locally available resources like timber, scrap metal, junk electronics, and other waste material. We have a variety of small wind turbines to match different needs. We created our own generators by salvaging damaged car starter motors, alternators, and diesel generators. From these, we made permanent magnet generators of up to 10 Kilowatts. We achieved this by creating our own coils and reconstructing the rotor to be a permanent magnet.

Here is a list of components used:

1. ArduinoLEDs

4. Relay Module

5. 12V DC motor

6. Wooden Blades

7. IR Sensor

8. Generator

9. Tower

10. Cables

Blade design

We then fabricated aerofoil blades from timber due to its wide availability and affordability. Using free airfoil designs from National Advisory Committee for Aeronautics (NACA) aerofoil database like NACA 4412, we designed the hub, shaft, and tower systems to hold the blades.

Braking and safety algorithm:

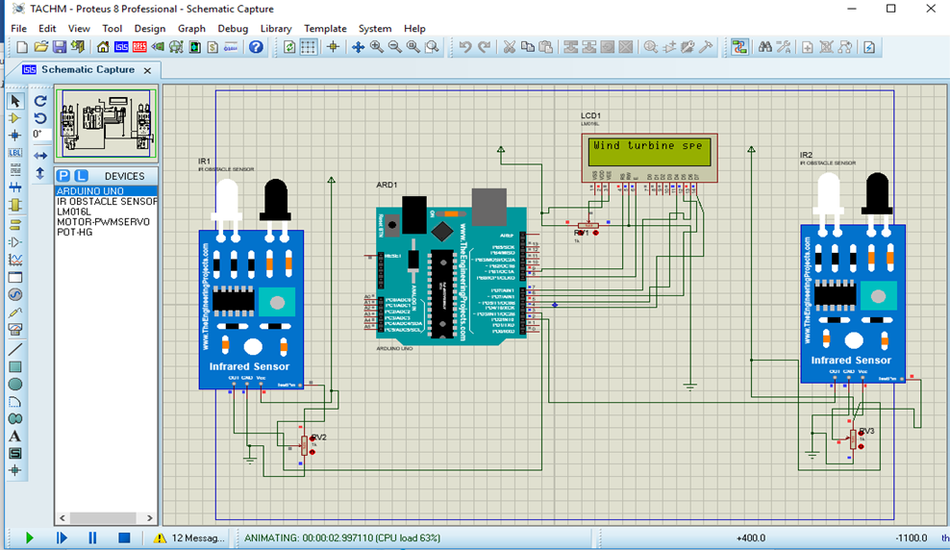

In order to make the wind turbines smart, we used Arduino Uno based on an AVR ATMega32 microcontroller and an Infrared (IR) sensor. The IR sensor measures the speed in Rotations Per Minute (RPM) of the blades and interfaces with Arduino. We have designed an algorithm to guarantee safety. Fig. 2 shows a circuit simulation of the RPMcounter in Proteus.

If the speed goes above the maximum safe limit, Arduino interacts with a 12V DC motor on the wind turbine tail vane to move the turbine blade out of the wind. It does this by activating a 5V DC single-channel relay module to switch on the DC motor.

The wind interacts with the wind turbine blades as a prime mover and rotates the generator which produces electricity. The IR sensors and relay module are connected to Arduino. As mentioned before, the IR sensor measures the speed of the blades and when the speed is within safety limits specified, a green LED indicating safety turns on.

A 12V DC motor is placed to control the tail vane. If the speed of the blades goes beyond safety limits, the microcontroller triggers the relay connected to the DC motor and switches it on. As a consequence, the windmill is rotated in a direction perpendicular to the wind flow to break the operation.

Component reengineeringGenerator reengineering:

We used a 2.5 Horsepower (HP) petrol generator to make our wind turbine, but since it was a 2 pole machine, we needed a speed of 3,000 RPM to generate power at a frequency of 60Hz, which is too high for most places. Hence, we switched to a permanent setup by using magnets from a car starter motor on the rotor. It produced power at the required frequency at a speed of just 900 RPM.

Gearing

In order to make the small wind turbine still useful even in low-speed areas, we used gears to multiply the speed.

Using angle grinder gearing plus 2 pulleys with a 2:1 ratio, we achieved speed multiplication of about 6 times, thus the wind turbine required to rotate slowly to achieve the desired 50Hz frequency.

Applications of prototype

Education

Can power a primary school block

Can be scaled to power projectors and other equipment required teaching

Healthcare

Can light rural health centres that are challenged with maternity cases

Can be scaled to power health equipment required in rural settings

Housing

Basic lighting of rural houses

Powering small cooking and heating appliances to replace fuelwood, charcoal and other environmentally unfriendly forms of energies

Lighting a small trading centre with a barbershop, saloon etc

Agriculture

Can be used for powering water pumping and irrigation systems

Small businesses.

Businesses like saloons and barbershops in rural areas can use small wind turbines and therefore improve their livelihoods and low-income levels, again reducing severe consequences of unemployment and poverty

Technicalities specifications

Technical attribute | Specification |

Rated power output | Different sizes Range from 2Kw for now to as low as 30 Watts |

Height of turbine | Maximum of 10 meters for now. |

Level of technology/automation | Arduino based monitoring. Software for remote monitoring |

Maximum speed | 4,000 RPM for a 2 KW design. |

Faults and maintenance | Easy to fix, easy to dismantle. |

Conclusion

Generating power where it is going to be used can cut down the costs of electricity transmission by a great margin. It also makes electricity available to remote locations where supply lines haven’t reached yet. A hybrid model of grid-connected and off-grid renewable systems can work together to balance sustainability and availability.

About the University Technology Exposure Program 2022

Wevolver, in partnership with Mouser Electronics and Ansys , is excited to announce the launch of the University Technology Exposure Program 2022. The program aims to recognize and reward innovation from engineering students and researchers across the globe. Learn more about the program here.