Techgest Unlocks Industry 4.0 for Manufacturers with Smart ERP Integration

By utilizing the Arduino Portenta Machine Control, Techgest helped manufacturing clients improve real-time monitoring, energy efficiency, and production optimization – all without vendor lock-in or costly retrofits.

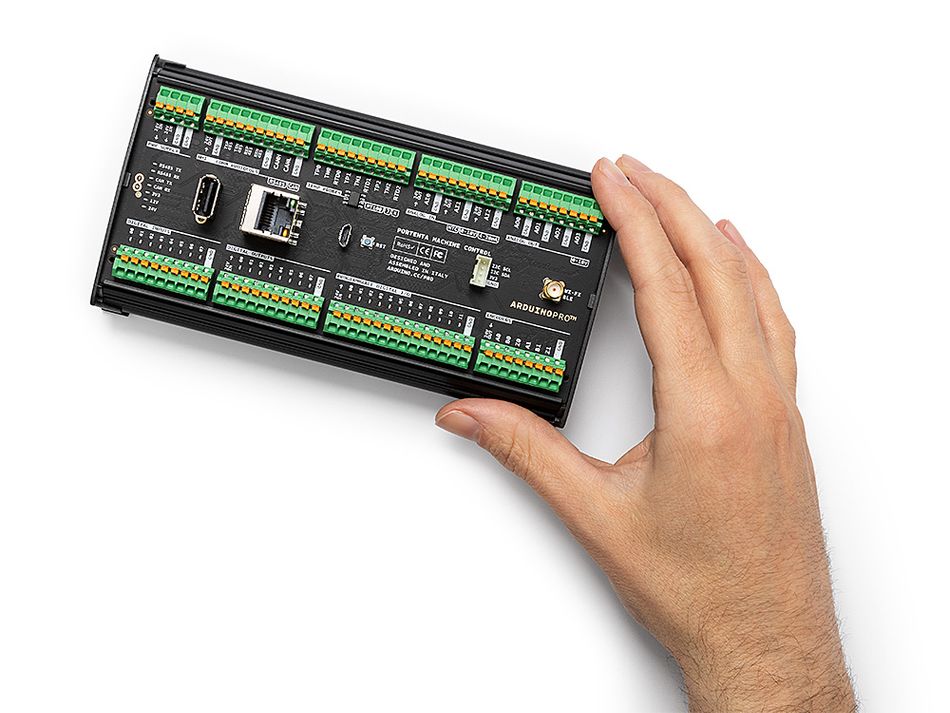

The Arduino Portenta Machine Control brings Industry 4.0 within reach for any manufacturer.

The Challenge: Simplifying Data Integration in Complex Manufacturing Environments

Techgest is a leader in ERP integration and software development, delivering custom solutions to a wide range of clients – from mechanical manufacturing to fashion. One consistent challenge they noticed across all industries is managing the massive volumes of data generated by industrial operations. Therefore, the company set out to develop an affordable, highly adaptable IO device that could facilitate seamless data integration with their TechTree MES platform, while also enabling real-time monitoring and efficiency improvements.

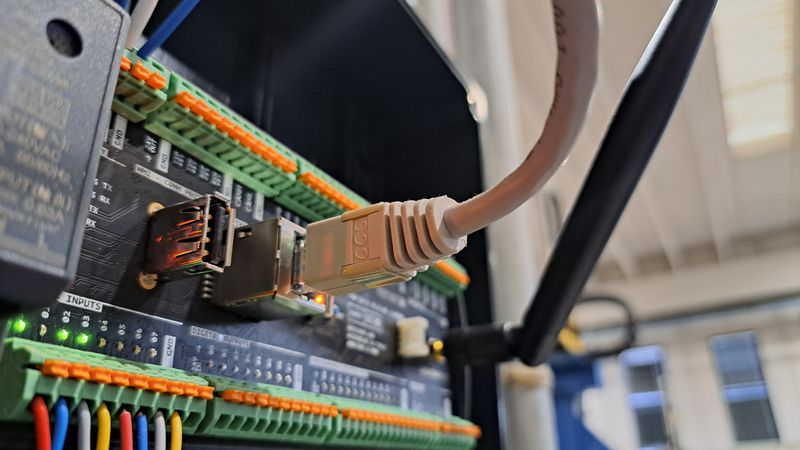

The result is TechIO, a device that can be implemented quickly and works across a range of equipment, independent of third-party platforms, to enable seamless integration of production data with their proprietary MES and WMS platform.

A Flexible, Open-Source Solution for Data Acquisition

To meet these goals, Techgest turned to the Arduino Portenta Machine Control. This powerful, open-source control unit provided the flexibility needed to develop a custom IO device with full API support, allowing clients to integrate even legacy production machines into TechTree. Its customizability and cost-effectiveness enabled Techgest to implement TechIO swiftly, keeping costs under control while avoiding the limitations of vendor-specific solutions.

According to Stefano Girardi, CEO of Techgest, “We evaluated various standard IO interfaces but found them lacking in terms of power and customization. We needed a solution that would allow us to build our own system exactly as imagined, without vendor lock-in.”

Benefits of TechIO for Manufacturers

TechIO enables manufacturers to leverage the real-time capabilities of the TechTree platform. Clients can now monitor production processes in real time, improve energy management, and enhance quality control KPIs, all without expensive retrofitting. One customer shared that the cost savings from energy efficiency alone helped them justify an investment of approximately €1 million in just 18 months, making TechIO a smart solution for boosting both operational and financial efficiency.

Curious to find out more? Read the full case study on the Arduino website.