The Future of Spare Parts: How 3D Printing Upgrades the Right to Repair

The Right-to-Repair movement is making waves, pushing for greater access to spare parts and repair options. However. many companies are uncertain about how to meet this growing demand. One promising solution lies in the potential of 3D printing.

3D Printing and the Right to Repair

The consumer movement advocating for longer-lasting appliances has gained momentum in recent years. New regulations are granting consumers the right to have their devices fixed even after the warranty expires. This shift signifies a new era where repairability, sustainability, and consumer empowerment are valued. However, ensuring affordable replacement parts remains a key challenge. This article explores the Right-to-Repair movement and how 3D printing offers practical solutions that empower consumers while addressing economic concerns.

The Right-to-Repair Movement: Empowering Consumers

Frustration with the increasing difficulty of repairing modern appliances has fueled the Right-to-Repair movement. Manufacturers often design sleek devices with integrated systems, making even simple repairs challenging. Consumers are forced to either pay for expensive repairs from authorized service centers or replace the entire product. This financial burden and unnecessary waste have driven calls for legislative reforms to ensure the right to repair appliances.

These efforts have gained traction in various regions. Following existing regulations in the European Union, Right-to-Repair laws are gaining momentum in the United States. Four states have already passed legislation in 2023 mandating manufacturers to provide replacement parts for a specified duration. Additionally, 30 other states are considering similar bills across different industries and devices. With readily available replacement parts, consumers can extend the lifespan of their products, saving money and reducing their environmental impact.

Challenges for Manufacturers: Navigating Compliance

While the Right-to-Repair regulations benefit consumers, they present challenges for manufacturers. Companies must now manage spare parts inventory for extended periods, balancing compliance with business operations. Inventory costs, logistics, and obsolescence become pressing concerns, requiring innovative solutions to ensure regulatory compliance without sacrificing efficiency or profitability.

3D Printing: A Game-Changer in Manufacturing

Additive manufacturing, also known as 3D printing, offers a potential solution to this challenge. New legislation allows independent repairers to use second-hand or 3D-printed spare parts. This shift presents both opportunities and challenges for Original Equipment Manufacturers (OEMs). There is concern about potential revenue loss from independent suppliers selling 3D-printed parts. However, this also presents a unique chance for OEMs to revise their aftersales strategies and embrace innovative approaches.

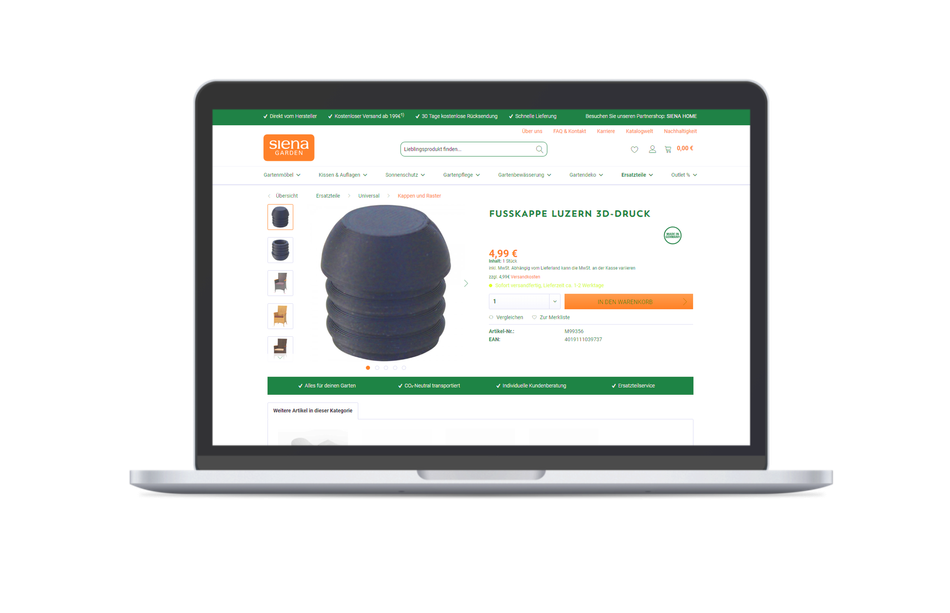

By leveraging 3D printing technologies themselves, companies can produce spare parts on-demand, eliminating the need for extensive inventory storage and reducing lead times. The flexibility of 3D printing allows for customization, enabling manufacturers to meet consumer demand with greater efficiency and responsiveness. By incorporating 3D printing into their operations, OEMs can not only meet the evolving demands of the market but also innovate and differentiate themselves in a competitive landscape.

3D Printing Platforms Redefining Spare Part Supply Chains

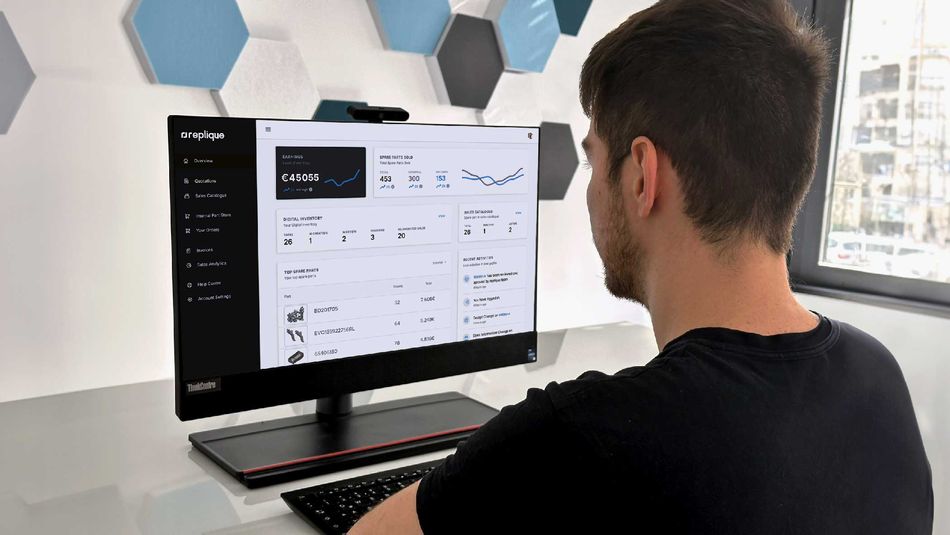

Integrating 3D printing might seem like a significant investment at first. However, platforms like Replique exist to make getting started easier and more accessible. These platforms allow companies to leverage the opportunities of 3D-printed spare parts without risks.

Central to Replique's approach is the concept of a digital inventory, which eliminates the need for companies to maintain costly physical inventories of spare parts. Businesses can leverage a digital platform to store part designs securely and produce them on-demand through a network of trusted 3D printing service bureaus. This offers access to a variety of 3D printing technologies and materials, and 3D printing expertise is not required. This enables a flexible and cost-effective solution for OEMs adapting to the changing landscape of consumer repair rights.