The making of micro-precision nozzle plates: 3D Printing, Laser Cutting, Micro Milling, Micro Punching, and Electroforming compared

Micro-fabricated nozzle plates are used in various industries, such as inkjet printing, medical devices, and flow control. Manufacturing these nozzle plates requires precision and accuracy to achieve the desired performance. Several production technologies can be used to manufacture micro-fabricated metal nozzle plates, such as 3D printing, Laser Cutting, Micro Milling, Micro Punching, and Electroforming. In this article, we will introduce these production technologies, and illustrate how to find your preferred process for the production of micro-fabricated nozzle plates based on key features such as precision, customization, scalability, and material compatibility.

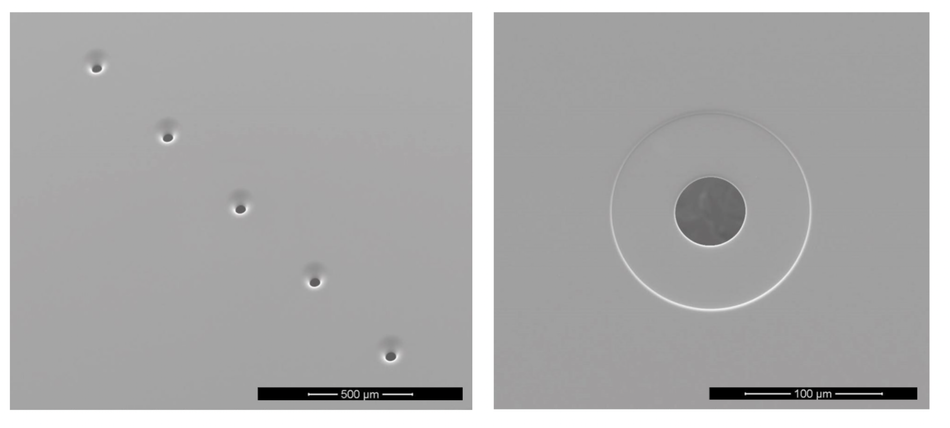

electroformed micro nozzle

3D printing is a well-known Additive Manufacturing technique, it can create three-dimensional objects by depositing materials layer by layer. Processes such as SLA (stereolithography) and DLP (digital light processing) are in particular known for high precision and resolution. While it is compatible with various materials, including polymers, metals, and ceramics, and commonly used in rapid prototyping as it enables fast design iterations, it may not achieve the same level of precision as other techniques such as Electroforming and lacks the capacity for high volume production runs.

-> Learn more about the comparison of Electroforming and 3D Printing

Laser Cutting uses focused laser beams to cut through materials, creating precise patterns and shapes. With Laser Cutting, intricate patterns with tight tolerances can be achieved. Although there are other advantages such as high precision and a wide range of compatible materials, it also has some limitations, such as HAZ (heat affected zones) which is thermal damage from the laser process.

-> Learn more about the comparison of Electroforming and Laser Cutting

Micro Milling is a Subtractive Manufacturing process that involves the removal of material using rotating cutting tools with very small diameters. This technique works with various materials, such as metals, ceramics, and polymers, and can achieve tight tolerances and smooth surface finishes. On the other hand, due to its vibration/rotating feature, an additional process for stabilization might be required when high precision cannot be compromised.

-> Learn more about the comparison of Electroforming and Micro Milling

Micro punching uses robust ‘masters’ to punch holes in (mostly metal) substrates. As nozzle specifications have ever tighter tolerances, fewer masters can be used in parallel to reduce the variation. This slows down the production process while increasing the price.

Electroforming is an additive manufacturing method that combines lithography with highly controlled electrodeposition which is highly suitable to create metal parts with micro holes of any shape. The lithography allows for small feature sizes with tight tolerances while electrodeposition grows a large number of parts in parallel without local damage or deformations. By combining several lithography and electrodeposition steps Electroforming can also integrate micro nozzles with channels, distance holders, or filtration structures.

When comparing 3D printing, Laser Cutting, Micro Milling, and Electroforming, many factors come into play. The choice of technology for producing micro-fabricated nozzle plates depends on the specific requirements of the application and the desired characteristics of the final product. Here we compare 4 key factors: Precision, Customization, Scalability, and Material capability.

Precision: Electroforming offers the highest precision and accuracy, down to the sub-micron level, making it ideal for intricate structures and fine features. Laser cutting and Micro Milling offer good precision but may not achieve the same level of detail as Electroforming. 3D printing provides moderate precision, depending on the specific technology used (SLM, EBM, etc.).

Customization: Electroforming allows for a high degree of customization, enabling the creation of complex geometries tailored to specific applications and the integration of additional functionalities such as channels into a single part. Laser cutting and Micro Milling also offer customization capabilities, but their potential may be limited by the complexity of the desired design. 3D printing provides the greatest design freedom, allowing for the creation of complex geometries and internal structures that may be challenging or impossible to achieve with other methods.

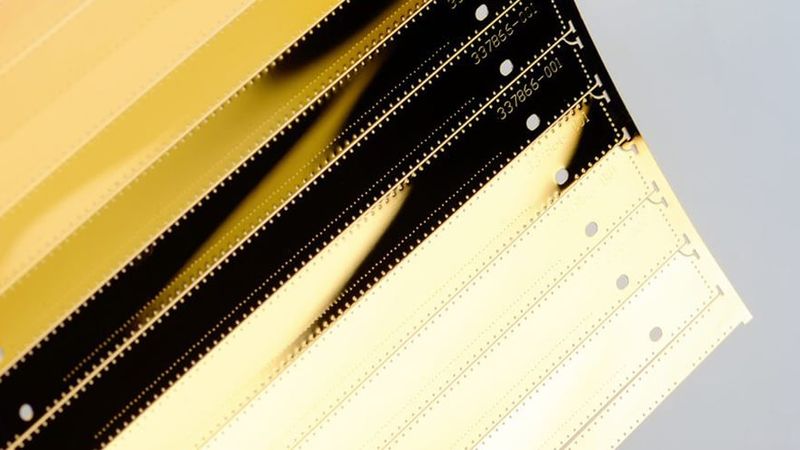

Scalability: Electroforming is well-suited for large-scale production due to its high repeatability and consistency across multiple production runs. Laser cutting offers a moderate level of scalability, depending on the specific setup and materials used. Micro Milling and 3D printing are better suited for small-scale production or rapid prototyping, as their efficiency may decrease in larger-scale applications.

Material Compatibility: Electroforming is focused explicitly on metal deposition, making it suitable for producing metal nozzle plates. Laser cutting and Micro Milling are also adaptable to a wide range of materials, such as metals, plastics, and ceramics. 3D printing can work with different materials depending on the specific technology, with metal 3D printing techniques like SLM and EBM being particularly relevant for nozzle plates.

In conclusion, Laser cutting, and Micro Milling provide normal precision and flexibility for applications not driven by extreme accuracy, while 3D printing offers unparalleled design freedom and material efficiency but is not comparable in precision. Electroforming excels in precision, customization, and scalability, making it particularly suitable for high-resolution and large-scale applications.

Electroforming: Additive Manufacturing atom by atom

Electroforming is an advanced Additive Manufacturing technology specialized for producing high-precision metal parts. Its uniqueness is that you can grow metal parts atom by atom, providing extreme accuracy and high aspect ratios. This process involves the use of an electric current to deposit layers of metal onto a substrate or mold, resulting in a highly accurate and precise reproduction of the original shape.

There are several key benefits that make Electroforming particularly well-suited for the production of micro-nozzle plates. Micro-nozzle plates require a high degree of accuracy and precision to function properly, and the Electroforming process can achieve this level of precision with a high degree of consistency. In addition, the Electroforming process is able to produce complex shapes with a high level of detail, which is critical in the production of micro-nozzle plates. These plates typically include a large number of very small nozzles, which require a high degree of accuracy and precision in order to function properly. Finally, Electroforming is a highly efficient and cost-effective manufacturing process, which is important in producing micro-nozzle plates. These plates are typically used in high-volume applications, where the ability to produce large quantities of parts quickly and efficiently is critical.