Utilizing 3D Printing To Create Pet Prosthetics

A New Jersey-based product development studio has paired with an algorithm developer and one of the nation’s leading animal orthotists to optimize the process of creating full-limb pet prosthetics.

With the increased accessibility and democratization of technologies that allow for rapid design iteration and customization, such as 3D printing, more and more innovative groups are taking the initiative to reevaluate how the use of this technology can improve upon existing systems. One of these groups is DiveDesign, who is working to use 3D printing to optimize the process of creating custom full limb pet prosthetics. In this article, we share their story: from the partnerships they’ve created, through the research and development that went into their new process, to the lives they’ve changed along the way.

Identifying An Opportunity

DiveDesign is the creation of Adam Hecht and Alex Tholl, who started their product development studio while still in college. While they mainly offer their services such as design research and strategy, concept development, prototyping, engineering, and brand development, their shared interest in technology has expanded their business and outlook towards finding opportunities for leveraging technology to improve upon existing systems used to design products.

The team discovered one of these opportunities through their introduction to Derrick Campana of Bionic Pets, a leading provider of animal orthotics and prosthetics. Campana has been creating animal orthotic and prosthetic devices since 2005, and has provided custom braces and prosthetics for thousands of animals throughout his career. From speaking with Campana, Hecht and Tholl learned of the frustrations involved with the current process of creating full limb prosthetic devices for dogs, which had the ability to become a large portion of Bionic Pet’s business.

Traditionally, to create a full limb prosthetic (when the dog is missing an entire front leg), a negative mold is created of the patient using 3M ACE style bandages that is hardened using Plaster of Paris. Then, plastic sheets are heated and bent around the negative mold. Afterwards, it is trimmed and finished, and the foam and leg hardware components are attached.

Although Campana has refined the process of creating full limb prosthetics, there were still many areas for improvement. While creating a brace takes little less than 2 hours, the process of creating a full limb prosthetic can usually take up to 15-20 (depending on the size of the prosthetic), and oftentimes does not account for adjustments after test fitting.

Hecht and Tholl realized that there was an opportunity to improve upon this process. Leaning on their experience with 3D printing and scanning, they partnered with Campana to create a new method for creating full limb pet prosthetics.

Designing A New Process

Hecht and Tholl began with the idea that by 3D scanning the negative mold and using the scan to create a 3D-printable customized prosthetic model, the need for heating, bending and finishing the plastic sheets would be eliminated, saving hours of manual labor.

In addition to saved time, there were other advantages to this new approach: by incorporating digital tools into the process, it was now easier to modify the prosthetic after test fitting if needed. Through 3D printing the prosthetic, there would be more options for materiality, which would allow the prosthetic to be optimized for comfort, breathability, and flexibility.

Another goal for the new process was to allow the workload to be distributed within a team, which was not an option with the existing process. “For example,” Tholl explained, “(in the past) if Derrick was too busy one week, no body jackets got made because he’s the only one who can make them. With the new process, we wanted to be able to train a team to support the process.”

With this in mind, the team began testing their new approach. They started by 3D scanning the Plaster of Paris molds and manipulating the scans with preexisting CAD tools. It was after preparing multiple prosthetic models for printing with these tools that they realized the extensive amount of manual digital labor that it required. “We knew that creating a digital tool to perform the same actions with minimal user input was the key to a sustainable model.” stated Hecht.

This realization led them to partnering with Chris Landau of Landau Design + Technology to create an algorithm specifically for generating prosthetic models from 3D scans to aid them in their process. Through this algorithm, it was possible to generate finalized 3D printable models of the prosthetics in a fraction of the time. It also allowed for further customization of each prosthetic through changing mount positions, thicknesses, and more.

Research & Development

With considerations towards cost, processing and printing time, and comfort, Hecht and Tholl designed and printed countless iterations of the prosthetics and worked with Landau to fine-tune the features of the algorithm. “To be honest, the first design was us making sure we could even print something that could fit a large dog and be comfortable. Derrick at Bionic Pets sat with us for many hours going over the importances of support placement, sizing, flexibility, strength.” Tholl recalled. “Not only did we want the new design to be faster to make, we also wanted it to be a better product for the dog.” Hecht added.

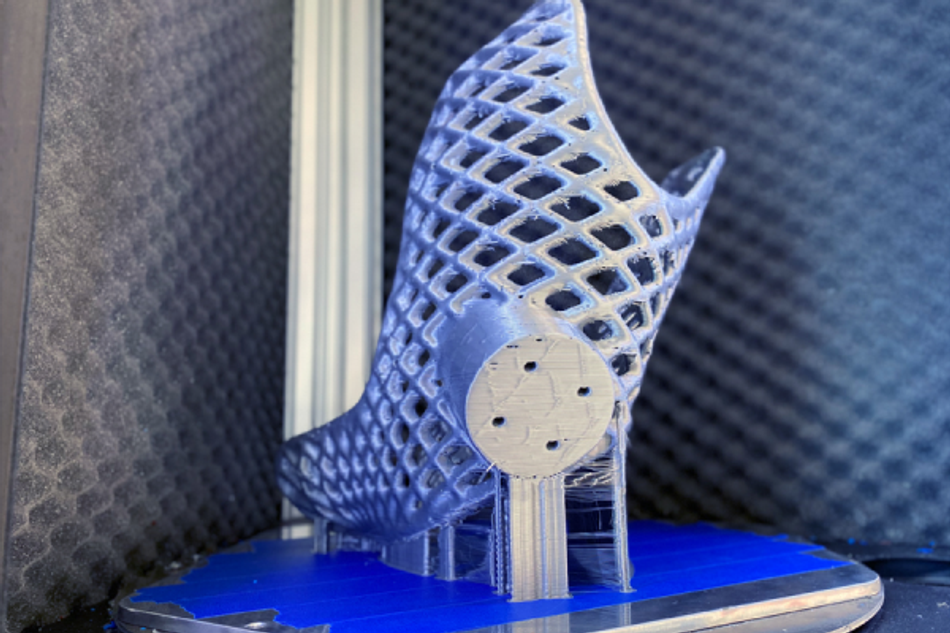

The largest challenge throughout development came with finding a material to print the prosthetics with. “We tried at least 10 different materials before landing on TPU,” Tholl stated. TPU, or thermoplastic polyurethane, is a plastic known for its elasticity and high abrasion resistance. “With this material we found the perfect combination of flex for comfort, and strength for support. It also enabled us to print a heavily ventilated pattern that enabled more breathability, unlike other materials that would have required being printed solid.”

Other characteristics of TPU that made it a good choice for printing the prosthetics were its microbial resistance, water resistance, and ability to be applied on or near the skin, which were important considerations when planning for the prolonged attachment to the patient.

As with any thorough design development, it was important to validate that the product would function as intended for the end user, and meet all the necessary comfort and safety requirements. However, this user validation was unlike any DiveDesign had tackled in the past. “It was tough because we had so many criteria to meet that would allow Derrick to approve our methods. Most importantly, we wanted to make sure that the fit was right. We were also looking to ensure that it moved with the dog and did not restrict them, was breathable and wouldn’t cause discomfort, and it could withstand the expected wear and tear.” explained Tholl.

Fortunately, there were pet families who were willing to participate in the initial testing under Campana’s supervision. This allowed DiveDesign to be confident that the prosthetics they were sending out to future patients were up to Campana’s standards.

One of these families were the owners of a dog named Hope, who volunteered to test one of the finalized prosthetics made through the new process. “Hope’s family really helped us to make sure what we were creating functioned in the way that it needed to, and Derrick was present digitally to watch and make sure his standards were being exceeded.” Hecht explained.

Through families like Hope’s, the team was able to conduct invaluable testing that allowed them to confirm that their process produced a viable alternative to traditional prosthetics, as well as better understand the unique challenges that came with every patient.

Creating The Prosthetics

Once the process had been tested and verified,the recurring orders for full limb prosthetics that Bionic Pets was receiving could be fulfilled using the new 3D printing-centric process. To date, the team has completed over 30 orders for prosthetics, with more coming in every day. As they are fine-tuning the process, the partnership between DiveDesign, Campana, and Landau has remained crucial. The prosthetics are being closely monitored by Campana, and the algorithm is continuing to be developed under the guidance of Landau.

While this endeavour has been a large undertaking for the team, the joy of seeing their prosthetics being used to change the lives of pets and their families has made it well worth it. “Seeing (the pets’) progress as they learn to move with the prosthetic..seeing them run for the first time, it’s great to see.” Hecht said. “It’s like an indescribable feeling. Never in a million years did we ever think we’d be developing animal prosthetics using 3D printing.” Tholl added.

Looking To The Future

As production of the prosthetics continues, the team is keeping their mind on expanding their operations. With the assistance of 3D printing service centers such as gCreate in Brooklyn, NY, they are working to keep up with the large influx of orders they are receiving each month.

For Hecht and Tholl, this project has inspired them to continue finding ways to use the technology they have available to them to solve problems and help others. “We are excited to see where we will go from here, and what further applications for 3D printing we will find in the future.” said Tholl.

You can learn more about this project through DiveDesign’s website, and by following DiveDesign and Bionic Pets on Instagram. You can also learn more about the story of two of their patients, Turbo Roo & Thor, on Campana’s new show The Wizard of Paws on BYUtv.

References: