What is Metal 3D Printing?

Metal 3D Printing is an advanced manufacturing method that builds metal parts from a CAD file using a layer-by-layer technique known as additive manufacturing.

Introduction to Metal 3D Printing

To understand metal 3D Printing, we first must understand the difference between “what it’s made of” (the material) and “how to make it” (the technique). Metal refers to the category of materials that we use and 3D Printing – also known as Additive Manufacturing (AM) – refers to the category of material processing techniques that consolidate the metal materials, one layer at a time, from the bottom up. Software is used to slice a solid three-dimensional (3D) computer generated model into a set of layers for the 3D printer hardware. The first layer attaches directly to a dedicated build plate, the second layer fuses with the first layer, and so on. In metal 3D Printing, production builds can consist of thousands or tens of thousands of layers and can take days, weeks, or even months to complete.

The first step in the process is to attach the initial layer of metal to the build plate successfully. Subsequent layers are added one-at-a-time, until the 3D geometry is realized.

The particulars of exactly how the metal is attached to the build plate, and subsequently to previous layers of the build, is where things get interesting and processes differ from one another. Methods of realizing metal 3D geometries differ primarily in two dimensions: 1) by the feedstock delivery system used (the way new material is fed into the system), and 2) by the consolidation mechanism leveraged (the physics of how the new material is fused to the build plate and to previous layers).

Metal 3D Printing Processes

As the metal 3D Printing industry continues to grow in scale and complexity, especially in the automotive, maritime, medical, aerospace, and space industries, more and more R&D-grade and production-level solutions continue to be developed. This proliferation of technology is a potential boon for advanced manufacturers across the globe; however, not all metal 3D Printing processes are created equally. As mentioned, each process comes down to 1) how new material feeds into the 3D printer, and 2) how that material is consolidated into a 3D geometry. At the time of writing, there are several popular industrial solutions on the market, listed here in order of perceived popularity.

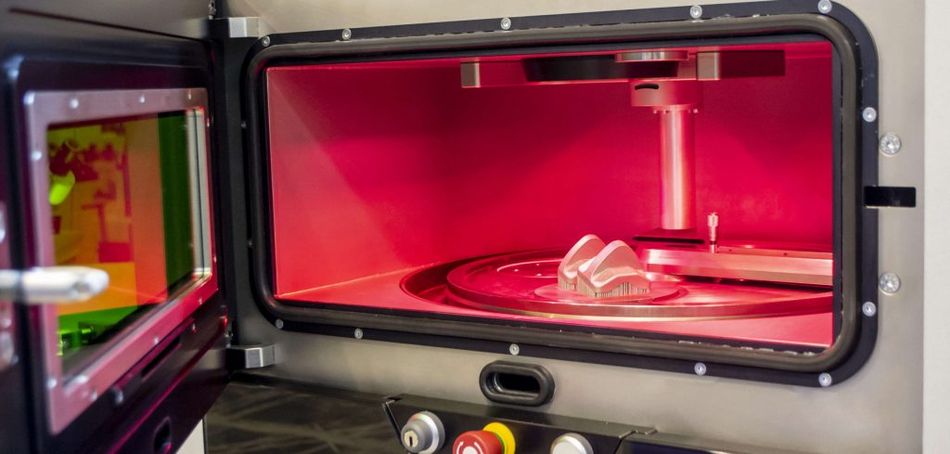

- Powder Bed Fusion (PBF)

- Feedstock: Metal Powder

- Consolidation Mechanism: High Temperature Laser or Electron Beam Melting

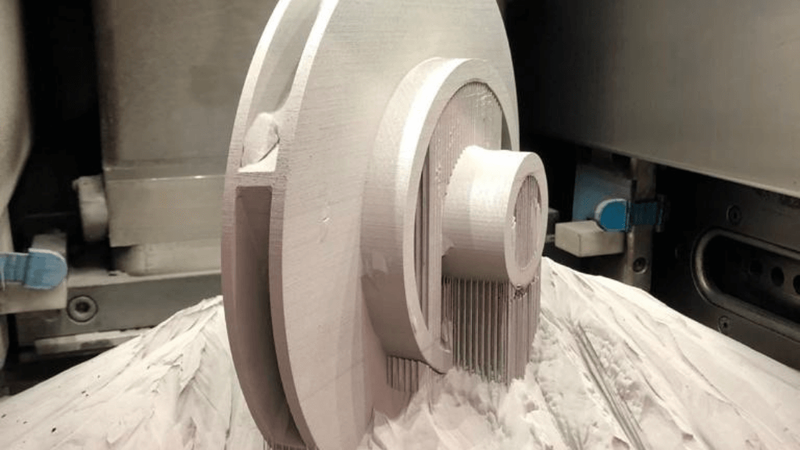

- Binder Jetting (BJ)

- Feedstock: Metal Powder and Chemical Binder

- Consolidation Mechanism: Chemical Binding and Heat Treating

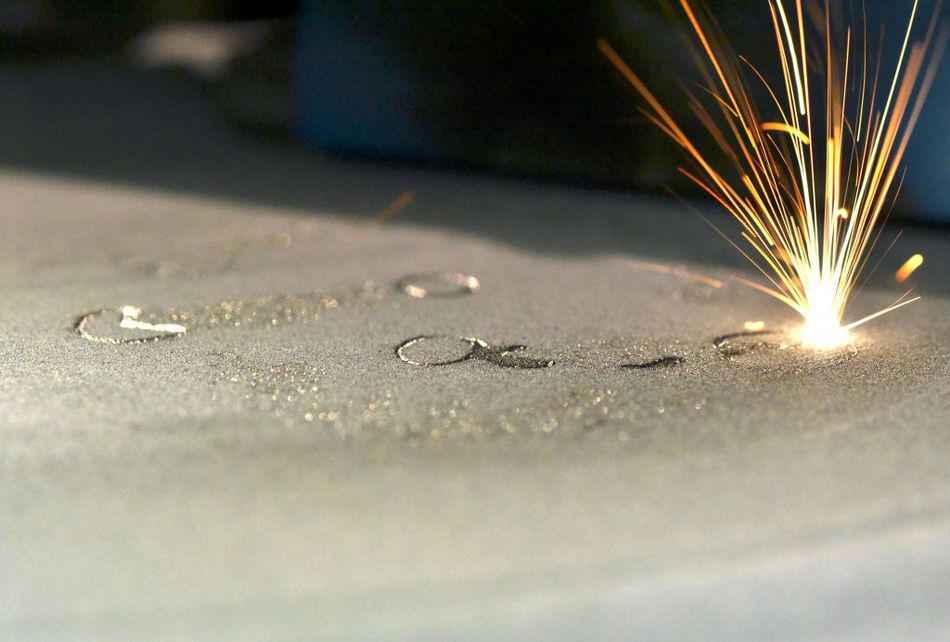

- Direct Energy Deposition (DED)

- Feedstock: Metal Powder or Wire/Filament

- Consolidation Mechanism: High Temperature Laser or Electron Beam Melting

- Bound Powder Extrusion (BPE)

- Feedstock: Metal Powder encapsulated in Polymer

- Consolidation: Low Temperature Conduction Melting, Polymer Removal, and Sintering

There are several industry-leading manufacturers that use each technology, and more competitors are entering these spaces all the time as the global metal 3D Printing ecosystem evolves and grows. We will dive further into the details of each process above in future articles in this series on Metal 3D Printing – stay tuned!