Your Guide to Using and Maintaining 3D Printer Air Filters

In this article, we look at the importance of using a 3D printer air filter to remove potentially harmful fumes from the print environment, as well as the different kinds of filter available and how to ensure proper maintenance.

Safety precautions like 3D printer enclosures can enhance the efficiency of air filters.

3D printer air filters help to maintain the cleanliness and safety of the environment by removing particulate matter and potentially harmful fumes emitted during the 3D printing process. So whether you’re a beginner hobbyist or a professional user, understanding how to use and maintain 3D printer air filters is essential to ensuring a healthy workspace, as well as to achieving optimal printer performance. This guide provides in-depth knowledge about 3D printer air filters, covering the importance of using them with FDM 3D printing, how to choose the right one for your setup, and finally how to maintain the 3D printer air filter for long-term efficiency.

The Need for Air Filters in 3D Printing

In the FDM 3D printing process, thermoplastic filaments are heated to their melting point and extruded through a nozzle to build parts layer by layer. Because the process uses heat to melt the thermoplastic materials, the process can produce microscopic particles and volatile organic compounds (VOCs) during operation. The ultrafine particles, measuring up to 1 μm, can become airborne and potentially pose health risks if inhaled by users over extended periods.[1] Similarly, VOCs, depending on their specific composition, can have varying degrees of harmful effects on health, from mild irritation to more serious long-term impacts.

Research indicates that certain types of 3D printing filaments, such as Acrylonitrile Butadiene Styrene (ABS), are more prone to produce harmful particulates and VOCs compared to other materials like Polylactic Acid (PLA).[2] This is because when ABS is heated up in the 3D printing process it releases styrene, a VOC known to be harmful to humans. It is therefore generally recommended to print in a well ventilated space and to use 3D printer air filters, which remove volatile organic compounds and other matter from the air and mitigate health risks.

Moreover, airborne particles and VOCs can accumulate on the surface of the 3D printer and its surrounding area, leading to potential contamination of printed objects and components of the 3D printer itself. Therefore, air filtration is crucial not just for human safety but also for maintaining the integrity of the 3D printing process.

Recommended reading: PLA vs. ABS and More - Choosing the Right Filament

Ultrafine particles

The first health risk posed by FDM 3D printing is due to the generation of ultrafine particulate matter (PM). Less than a micron in size, these particles can have a significant impact on air quality and human health. They are tiny enough to be inhaled deeply into the respiratory tract, posing potential health risks. Studies show that prolonged exposure to high concentrations of these particles in the air can lead to short and long-term respiratory and cardiovascular issues.[3]

These particles are particularly concerning because of their ability to remain suspended in the air for extended periods. They can be transported by air currents and spread over larger areas, affecting more than just the immediate vicinity of the 3D printer. Due to their small size, these particles can easily evade the body's natural filtration mechanisms, such as nose hairs and the mucous lining of the respiratory tract, and reach the lungs and even the bloodstream.

The role of a 3D printer air filter is to effectively capture these microparticles, thereby reducing their concentration in the air. High-efficiency particulate air (HEPA) filters, for instance, can remove 99.97% of particles as small as 0.3 microns in diameter.[4] Hence, the use of a suitable air filter can significantly mitigate the impact of microparticles generated during 3D printing.

Volatile Organic Compounds (VOCs)

The potential chemical hazards in 3D printing arise primarily from the volatile organic compounds (VOCs) released during the printing process. Different types of filaments emit different VOCs when heated. For example, ABS filaments can emit styrene when printed, which is a hazardous substance known to have wide ranging health impacts when breathed in at high levels, including tiredness, slower reflexes and responses, difficulty concentrating, vision problems, and more.[5]

Styrene is classified as a Group 2B carcinogen by the International Agency for Research on Cancer (IARC), which means it is possibly carcinogenic to humans.[6] Chronic exposure to styrene can result in irritation of the skin, eyes, and the respiratory tract. It may also lead to gastrointestinal effects and impact the central nervous system, causing symptoms like headache, fatigue, and weakness.

Other filaments such as nylon can produce caprolactam when heated, Caprolactam is a VOC and irritant, exposure to which can lead to irritation of the eyes, skin, and respiratory tract. The National Institute for Occupational Safety and Health (NIOSH) has set a recommended exposure limit for caprolactam at an average of 1 milligram per cubic meter (1 mg/m³) over a 10-hour workday.[7] PETG, another common filament, can also generate potentially hazardous compounds.

Moreover, some filaments can contain additives like plasticizers, flame retardants, and pigments, which can potentially release additional VOCs or hazardous substances when heated. Given these potential chemical hazards, an effective 3D printer air filter system–specifically an activated carbon filter—is useful because it can trap the VOCs released in the 3D printing process.

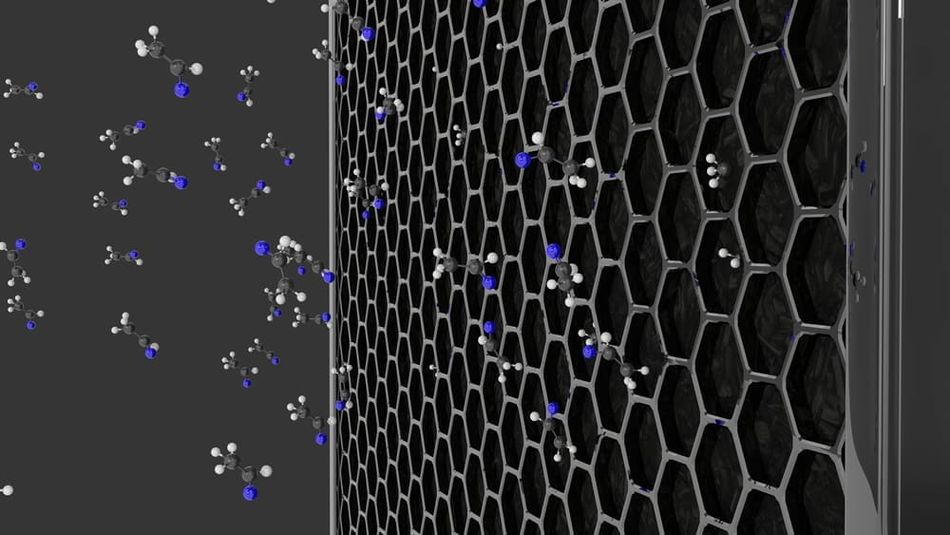

Air filters can intercept and remove particles and VOCs from the air.

Air filters can intercept and remove particles and VOCs from the air.

How a 3D Printer Air Filter Works

3D printer air filters function by intercepting and removing harmful airborne particulates and gases emitted during the printing process. This is generally achieved through a combination of mechanical filtration and adsorption mechanisms.

Mechanical filtration involves physically trapping particulates in a dense network of fibers, which make up the filter media. Adsorption works on a molecular level, where gas molecules are attracted to and held on the surface of adsorbent materials, such as activated carbon.

The efficiency of an air filter in a 3D printer largely depends on its design and the materials used. Typically, a 3D printer air filter will have a multi-stage filtration system, with each stage designed to address specific pollutants. The first stage usually involves a pre-filter that captures larger dust particles, followed by a more refined filter such as a HEPA filter for smaller particles, and finally an activated carbon filter for adsorbing gases and VOCs.

Air drawn into the filtration system by an extractor fan first encounters the pre-filter, which traps larger particles and prevents them from clogging the subsequent filters. The air then passes through the HEPA filter, which can remove ultrafine particles. Finally, the air passes through the activated carbon filter, where gases and VOCs are adsorbed.

Recommended reading: 3D Printer Ventilation: A Comprehensive Guide

Filter Types and Their Functions

In the context of 3D printer air filters, there are two main types of filters: particulate filters and gas filters. Particulate filters, such as HEPA filters, are designed to remove airborne particles, while gas filters, such as activated carbon filters, are meant to adsorb gases and VOCs.

HEPA (High Efficiency Particulate Air) Filters: These are designed to capture small particles from the air. As per the U.S. Department of Energy (DOE) standards, a HEPA filter must remove at least 99.97% of airborne particles with a size of 0.3 microns. The mechanism through which HEPA filters work can be divided into three categories: interception, impaction, and diffusion. Particles larger than 0.4 microns are primarily captured through interception and impaction, while smaller particles are captured through diffusion.

Activated Carbon Filters: These filters are used to adsorb gases and VOCs that cannot be removed from the air by HEPA filters. The filter uses a large surface area of activated carbon (often, the activated carbon is porous to increase surface area), which adsorbs a wide range of gases. The adsorption process occurs when gas molecules are attracted to the carbon's surface and held there, effectively removing them from the environment.

For the best air filtration while 3D printing, it’s advisable to use both types of filter or a dual-filter system, to ensure that all ultrafine particles and gases are being removed from the air you breathe.

Air Flow and 3D Printer Enclosures

The efficiency of a 3D printer air filter system is strongly influenced by its air flow characteristics, which essentially determine how much air is processed by the filter within a given time. This is often quantified by the system's Clean Air Delivery Rate (CADR), which indicates the volume of clean air that an air purifier can deliver per unit of time.

An air filter's efficiency is also dictated by its ability to remove pollutants from the air. In this respect, the Minimum Efficiency Reporting Value (MERV) is often used as a benchmark. The MERV scale ranges from 1 to 20, with higher numbers indicating a greater ability to filter smaller particles.[8] For instance, a HEPA filter, which can remove 99.97% of particles as small as 0.3 micrometers, is typically rated between 17 and 20 on the MERV scale.

Air flow and filter efficiency are intertwined in determining the performance of an air filter system. High air flow can dilute the concentration of pollutants, but if the filter efficiency is low, pollutants will remain in the air. Conversely, a high-efficiency filter may not be effective if the air flow is not sufficient enough to bring the pollutants to the filter.

In the context of 3D printing, air flow is particularly important due to the localized nature of particle and gas emission. Effective air flow is essential for quickly guiding the pollutants to the filtration system as they are emitted and before they can be breathed in. 3D printer enclosures with built-in air filters can therefore be more effective at containing the pollutants and enhancing the quality of air compared to an open-air 3D printer.

To ensure optimal air flow, the air filter should be placed close to the 3D printer fume source, ideally within the printer enclosure. Furthermore, the enclosure should be designed to facilitate air movement towards the filter, preferably creating a laminar flow condition that helps minimize particle dispersion.

In terms of efficiency, both particulate and gas filter elements need to be tailored for the specific pollutants generated by 3D printing. As mentioned before, a combination of HEPA and activated carbon filters is often employed to deal with particles and gases respectively. The filtration efficiency can be further enhanced by optimizing the filter design and materials based on specific requirements, such as particle size distribution and gas composition.

Choosing a 3D Printer Air Filter

Choosing the right 3D printer air filter is important as it directly influences the quality of air in your printing environment and, by extension, your health. The choice should be based on several factors, such as the 3D printer, 3D printing frequency, the type of filament used, the size of the room, whether there is good ventilation, as well as your budget.

Cost vs. Efficiency

In the world of air filtration systems, the cost and efficiency of the filters often go hand in hand. Higher efficiency filters, such as those with a high MERV rating or True HEPA filters, tend to be more expensive than simpler filters with lower MERV ratings. These filters can remove smaller particles and more types of pollutants, resulting in cleaner air. However, they also tend to have a higher resistance to air flow and require more powerful (and often more expensive) fans.

When choosing a filter, it's important to balance the need for clean air against the cost of the filter. If you are printing occasionally with PLA filament in a well-ventilated room, a lower-cost filter might suffice. However, if you print frequently, especially with filaments that emit more harmful particles or gases, such as ABS, investing in a high-efficiency filter system that can trap VOCs might be more beneficial in the long run, despite the higher initial cost.

This balance between cost and efficiency is not a straightforward decision and depends on the specifics of your situation. Therefore, it's essential to understand your requirements thoroughly and conduct research before making a purchase. This might involve reading product specifications, checking MERV ratings or CADR values, and even consulting experts or users with similar printing conditions. It's also advisable to consider the long-term operational cost, including the electricity consumption of the system and the replacement frequency of the filter elements.

Compatibility with Your 3D Printer

Another thing to consider when choosing an air filter is its compatibility with your 3D printer. Not every air filter is designed to be used with all types of printers. For instance, some air filtration systems are specifically designed for certain printer brands or models, offering direct attachment points or fittings that match these printers. If you own one of these printers, these specific systems can provide a neat, integrated solution.

On the other hand, there are more generic filtration systems that are designed to work with a broad range of 3D printers. These systems might not offer as seamless a fit as the model-specific systems, but they offer the advantage of flexibility, especially if you own multiple different printers. Often, these systems work by enclosing the entire printing area or by attaching to the output of the printer's built-in fan.

One critical aspect to look at is the capacity of the filtration system compared to the size and emission characteristics of your printer. For instance, a large, commercial-grade 3D printer might require a high-capacity air filter system capable of handling a high volume of air. Likewise, if you are printing materials known to emit more harmful particulates or gases, such as ABS, you might need a filter designed to remove these specific pollutants effectively.

Lastly, check whether the system requires any modifications to your printer. Some systems might require you to install additional hardware or even modify the printer's casing or firmware. Be sure to evaluate your comfort level with these tasks and whether they might affect the warranty or operation of your printer. As always, check the specifications, consult user reviews or experts, and ensure that the filter system meets your specific needs before making a decision.

Maintaining a 3D Printer Air Filter

Ensuring proper maintenance of your 3D printer air filter is vital to ensuring its long-term effectiveness and performance. With proper care, the air filter can perform its role of capturing potentially hazardous ultrafine particles and VOCs, maintaining a safer printing environment.

One of the primary maintenance tasks involves regular monitoring the filter. This means checking for any visible signs of wear or damage, such as tears or deformities, and inspecting the filter's color. Over time, a filter can become darkened or discolored due to captured particles, a clear sign that it may be nearing the end of its service life. The pressure drop across the filter can also be a key indicator of its health. A higher pressure drop can mean the filter is getting clogged and needs replacement. Some advanced filtration systems come with built-in sensors that notify the user when it's time to change the filter.

Changing the Filter

The frequency of filter replacement depends on several factors, including how often you use your printer, the types of materials you print with, and the type of air filter you are using. Air filter and purifier manufacturers will usually provide a guideline on filter lifespan, typically gauged by hours of use, which can be a helpful metric for decided when to change your 3D printer’s filter.

Similarly, it's important to consult the manufacturer's instructions to ensure proper handling when swapping out an air filter. Fortunately, most air filters are easy to replace and require little to no tools. They often have a housing that can be easily opened or disassembled, allowing for the removal of the old filter and installation of a new one. It's crucial to remember that a used filter can be filled with potentially harmful particles captured during its service, so it's advisable to handle it carefully, preferably with gloves, and dispose of it in a way that reduces the risk of spreading these particles.

Replacement filters can often be purchased directly from the filtration system manufacturer, ensuring they fit and function correctly. Some filters are also reusable and can be cleaned, but the efficiency of such filters might degrade with each cleaning cycle, and they still eventually need to be replaced. The cleaning process, which we’ll dive into in the next section, usually involves using compressed air or a special cleaning solution, as specified by the manufacturer. However, note that not all filters are cleanable, and attempting to clean a non-cleanable filter can damage it and reduce its effectiveness.

Cleaning and Care

Besides replacing the filter itself, other components of the air filtration system also require care and attention to ensure optimal functionality. These components include the housing, fan system, and electronic sensors, if applicable.

Dirt and dust can accumulate on the surface of the housing, which can indirectly impact the efficiency of the system. To maintain the housing, it is advisable to wipe the exterior with a damp cloth periodically. While doing so, it's crucial to avoid any contact with the filter media to prevent any accidental damage.

The fan system, which draws air through the filter, can also accumulate dust over time. This accumulation can lead to reduced airflow, thereby negatively impacting the overall performance of the filtration system. To clean the fan system, start by disconnecting the power supply to ensure safety. Then use a can of compressed air to gently blow away dust and debris from the fan blades and housing. It's important not to use water or cleaning solutions as they can damage the electronic components.

In advanced air filtration systems, electronic sensors monitor the status of the filter and provide alerts when it's time for a change. These sensors require occasional dusting to maintain their accuracy. Compressed air can be used to remove dust from these sensors. However, it's vital to avoid direct contact to prevent damage.

Finally, always ensure the air filter is completely dry before reinstalling it into the printer after cleaning. This is important as moisture can cause growth of mold and bacteria, which could compromise the quality of air. It could also lead to corrosion of metal components. It's also recommended to allow the filter and other components to air dry in a clean environment, away from direct sunlight to prevent any UV damage.

Through regular cleaning and care, you can prolong the service life of your 3D printer air filtration system and maintain an optimal printing environment. Remember, each 3D printer air filter may come with specific maintenance instructions provided by the manufacturer. Always refer to these guidelines to ensure you're correctly caring for your specific model.

Recommended reading: How Does a 3D Printer Work?

Troubleshooting Common Air Filter Issues

Different issues can occur when using a 3D printer air filter, fortunately there’s a solution for the most common complications. Here are a few common problems and their corresponding solutions.

Reduced air flow: This is one of the most common problems. When reduced air flow occurs, the extraction of harmful emissions from the printer is not as efficient, potentially leading to hazardous conditions. The problem is often caused by a clogged filter and can be prevented with regular maintenance. Once the filter is clogged, it should be replaced. It's important to note that even a small amount of accumulation on the filter can reduce airflow substantially, as the pore size of these filters can be as small as 0.3 microns.

Noise: Another common issue is unusual noise coming from the air filter system. This noise can be caused by the fan or the motor. Dust and debris in the fan can disrupt its balance, leading to noise. The problem can usually be resolved by cleaning the fan using compressed air. If the noise persists after cleaning, it might be due to motor issues, which may require professional servicing.

False sensor alarms: False alarms from the electronic sensor indicating a filter change is another issue users might encounter. This could be due to dust accumulation on the sensor, leading to false readings. Cleaning the sensor with compressed air should resolve the issue. If the false alarms continue, it may be a sign of a faulty sensor which might need replacement.

Installation errors: There are also issues related to the installation of the filter. If the air filter doesn't fit properly in the designated slot, it might not function properly. In such cases, it's necessary to buy a filter with the correct dimensions as specified by the 3D printer manufacturer. Misalignment during installation can also lead to improper fit. It's crucial to follow the manufacturer's installation instructions to prevent such issues.

In all these instances, a good understanding of your 3D printer's specifications and the air filtration system will be beneficial. Always refer to the manual provided by the manufacturer, as it contains specific guidelines and troubleshooting steps for your particular model.

Advanced Topics in 3D Printer Air Filtration

Emerging advancements in 3D printer air filtration are improving the safety and efficiency of 3D printing operations. They are transforming traditional air filtration systems with innovative concepts and technologies.

Smart air filtration systems are an example of such advancements. These systems are integrated with sensors to monitor the air quality in real time. These sensors can detect the concentration of volatile organic compounds (VOCs) and ultrafine particles (UFPs), both of which are common emissions during 3D printing. Data from these sensors is used to adjust the filtration system's operation dynamically. For instance, if a higher concentration of VOCs is detected, the system can increase the fan speed to improve extraction, thereby ensuring a safer working environment.

High efficiency particulate air (HEPA) filters have been a standard in many applications for their efficiency, which can capture 99.97% of particles of 0.3 micron diameter. However, research is underway to develop Ultra Low Penetration Air (ULPA) filters for 3D printer applications. ULPA filters have an even higher efficiency, capturing 99.999% of particles of 0.12 microns.[9] Though ULPA filters have a higher pressure drop and are more expensive than HEPA filters, their superior performance might be necessary for certain high-precision or high-risk 3D printing applications. In other words, more for industrial usage rather than at-home 3D printing.

Finally, the idea of self-cleaning filters is gaining attention. These filters use various mechanisms such as electrostatic precipitation, photocatalysis, or ultrasonic waves to dislodge accumulated particles and clean the filter surface. Self-cleaning filters can potentially reduce the frequency of filter replacement and lower the maintenance effort. This technology is not currently linked to 3D printer air filters, but is more associated with industrial environments.

Conclusion

A combination of 3D printer air filtration and proper ventilation is critical to maintaining a safe and efficient 3D printing environment. It requires careful selection of air filters, regular maintenance, and the ability to troubleshoot common issues. Emerging advancements promise to enhance these processes, providing even better air filtration performance. By integrating these considerations and practices, operators can ensure that their 3D printing operations are both safe and effective.

FAQs

Q: What is the purpose of an air filter in a 3D printer?

A: An air filter in a 3D printer helps to reduce the concentration of potentially harmful particles and gases in the air. During the printing process, certain materials, such as ABS plastic, emit volatile organic compounds (VOCs) and ultrafine particles (UFPs) that can be harmful if inhaled.

Q: How often should I change the air filter in my 3D printer?

A: The frequency of changing the air filter in your 3D printer depends on the type of filter, the frequency and duration of your printing operations, and the types of materials you use. For example, a typical HEPA filter used in a moderate frequency operation may need to be replaced every six to twelve months.

Q: Can I use my 3D printer without an air filter?

A: While it's possible to use a 3D printer without an air filter, it's not recommended, especially when printing with materials such as ABS, which emit harmful particles and gases. Without proper 3D printer ventilation or filtration, these emissions can lead to poor indoor air quality, which may cause negative health issues.

Q: Can I make my own 3D printer air filtration system?

A: While it’s not advisable to build an air filter yourself, you can improve the air quality in your 3D printing environment by building a DIY enclosure. By installing a filter into the DIY 3D printer enclosure, you can further improve the air quality and lessen any risks associated with inhaling ultrafine particles and VOCs.

Q: What is a HEPA filter and why is it used in 3D printers?

A: HEPA stands for High Efficiency Particulate Air. It is a type of air filter that can trap 99.97% of particles that are 0.3 microns in diameter. HEPA filters are used in 3D printers because they are very efficient at capturing ultrafine particles (UFPs), which are commonly emitted during 3D printing.

Q: What are some signs that my 3D printer air filter needs to be replaced?

A: Signs that your 3D printer air filter needs to be replaced may include a noticeable increase in odors during printing, visible dust or debris accumulation on the filter, or decreased printer performance. In some cases, your 3D printer might also display a warning or error message indicating that the filter needs to be replaced.

Q: Does SLA 3D printing generate harmful emissions?

A: Stereolithography (SLA), also known as resin printing, does generate potentially harmful particles and VOCs. This means that an air filter or purifier is recommended when using a resin 3D printer. Users should also take safety precautions when handling liquid resin (such as gloves and goggles), since the material is considered toxic.

References

[1] EPA Researchers Continue to Study the Emissions of 3D Printers [Internet]. U.S. Environment Protection Agency. June 15, 2021. Available from: https://www.epa.gov/sciencematters/epa-researchers-continue-study-emissions-3d-printers

[2] Dosimetric and Toxicological Analysis of 3D Printer Emitted Particles [Internet]. Chemical Insights. December 2022. Available from: https://chemicalinsights.org/wp-content/uploads/2022/12/Chemical-Insights_3D-Toxicity-Report_final.pdf

[3] Schraufnagel DE. The health effects of ultrafine particles. Experimental & molecular medicine. 2020 Mar;52(3):311-7. Available from: https://www.nature.com/articles/s12276-020-0403-3

[4] What is a HEPA filter? [Internet]. U.S. Environmental Protection Agency. 2023. Available from: https://www.epa.gov/indoor-air-quality-iaq/what-hepa-filter

[5] Styrene [Internet]. CDC, 2023.

[6] Styrene ToxFAQs™ [Internet]. Agency for Toxic Substances and Disease Registry. June 2012. Available from: https://www.atsdr.cdc.gov/toxfaqs/tfacts53.pdf

[7] CAPROLACTAM [Internet]. United States Department of Labor OSHA. January 2021. Available from: https://www.osha.gov/chemicaldata/34

[8] What is a MERV rating? [Internet]. U.S. Environmental Protection Agency. 2023. Available from: https://www.epa.gov/indoor-air-quality-iaq/what-merv-rating

[9] HEPA Filters and ULPA Filters Information [Internet]. GlobalSpec. 2023. Available from: https://www.globalspec.com/learnmore/manufacturing_process_equipment/filtration_separation_products/hepa_filters_ulpa_filters

Table of Contents

The Need for Air Filters in 3D PrintingUltrafine particlesVolatile Organic Compounds (VOCs)Air filters can intercept and remove particles and VOCs from the air.How a 3D Printer Air Filter WorksFilter Types and Their FunctionsAir Flow and 3D Printer EnclosuresChoosing a 3D Printer Air FilterCost vs. EfficiencyCompatibility with Your 3D PrinterMaintaining a 3D Printer Air FilterChanging the FilterCleaning and CareTroubleshooting Common Air Filter IssuesAdvanced Topics in 3D Printer Air FiltrationConclusionFAQsQ: What is the purpose of an air filter in a 3D printer? Q: How often should I change the air filter in my 3D printer? Q: Can I use my 3D printer without an air filter? Q: Can I make my own 3D printer air filtration system?Q: What is a HEPA filter and why is it used in 3D printers? Q: What are some signs that my 3D printer air filter needs to be replaced? Q: Does SLA 3D printing generate harmful emissions?References