Battery chemistries for construction EVs

Image credit: Volvo

NMC and LFP lithium-ion batteries find favor in different regions as OEMs move to electrify larger excavators and loaders.

This article was first published on

www.sae.orgFREE REPORT: Reducing Human Driver Error and Setting Realistic Expectations with Advanced Driver Assistance Systems

Thousands die or are injured each year in automobile crashes. Bringing automated driving systems technologies into the advanced driver assist systems (ADAS) and connected vehicle space will help humans drive more safely and better prepare us for automated vehicles (AVs).

Learn more about ADAS and ADS implementation with the goal of reaching zero deaths and serious injuries by downloading this FREE report from SAE International (valued at $50).

Electric vehicles in the construction industry

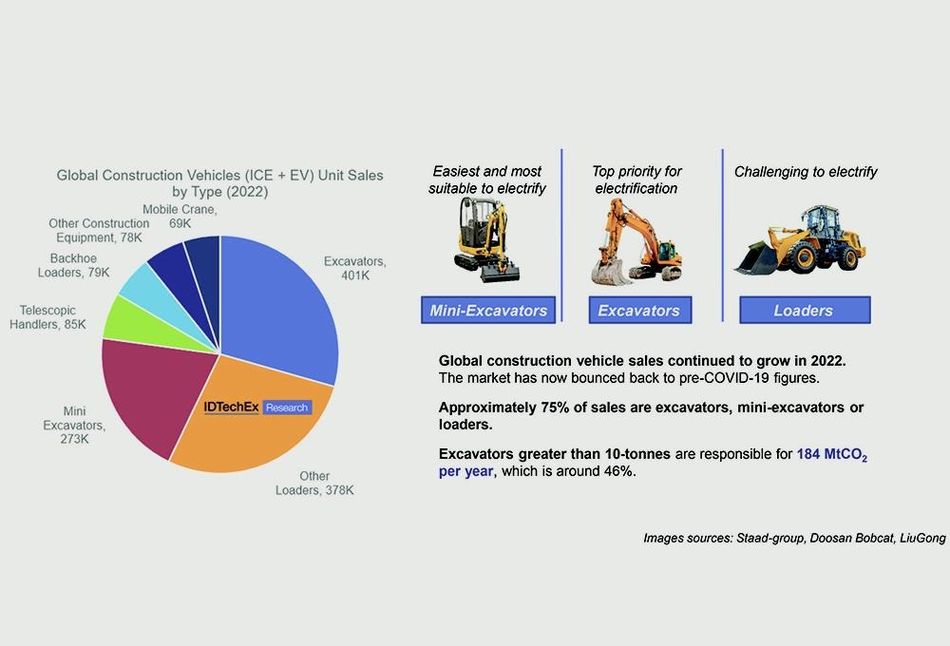

The success of electric vehicles in the construction industry will largely be determined by battery prices being low enough that the total cost of ownership is cheaper than diesel alternatives. IDTechEx’s new report, “Electric Vehicles in Construction 2023-2043,” shows that there is a battery price tipping point, under which it will be cheaper over the vehicle lifetime to operate an EV. Selecting the right chemistry will be imperative for getting a low enough vehicle price. So why is a clear dichotomy seen between the batteries being deployed in China compared to Europe?

Electric vehicles in construction are an emerging market. IDTechEx has built a database of more than 100 example makes and models across seven different construction-vehicle categories: mini excavators, excavators (>6 tonnes), compact loaders, backhoe loaders, wheel loaders, telehandlers, and mobile cranes. However, with lots of vehicles yet to be released, only 49 database entries have confirmed chemistry information.

Europe and China have more established markets for electric construction vehicles, which makes it possible to draw some conclusions about battery-chemistry trends from OEMs in these regions. What is obvious at this early stage is that Europe heavily favors NMC (nickel manganese cobalt) lithium-ion batteries, while China has chiefly chosen LFP (lithium iron phosphate) batteries.

Battery requirements in construction vehicles

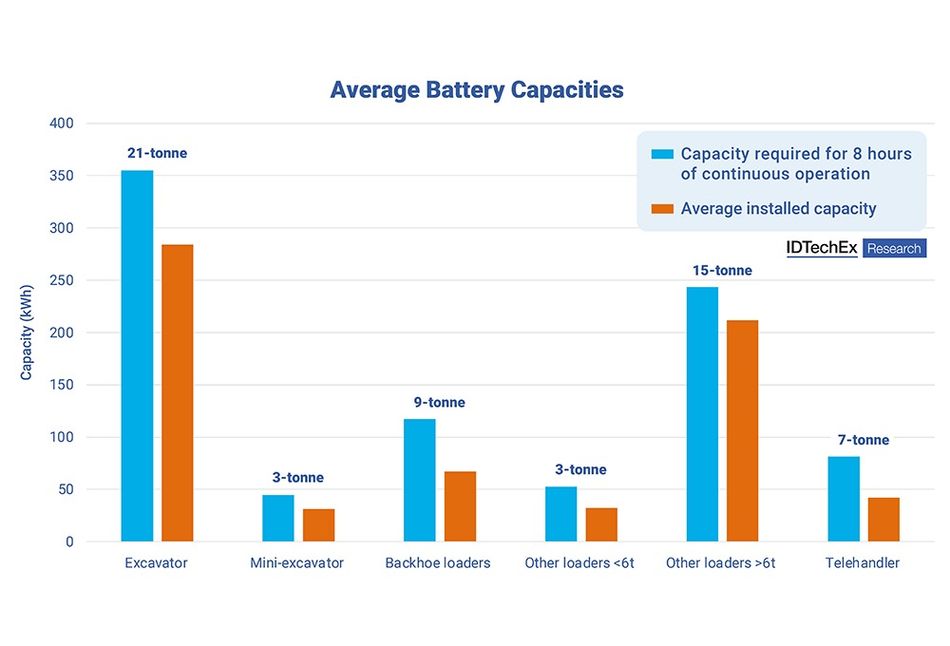

So, why would one select NMC, LFP or even lead acid? A battery that electrifies construction equipment needs to have huge capacity and low cost. Some of these machines are extremely large and usually require concrete counterbalances to handle the massive loads they encounter. What this means for electrification is that battery weight isn’t much of an issue.

Power density also is not a priority. Unlike electric cars, construction vehicles do not tend to have large power-demand spikes and are more likely to operate at a steady rate for a long time. As an example, some early Tesla Model S EVs had a 60kWh battery and a 210kW motor power, meaning its battery must be able to deliver a peak of 3.5C (power divided by capacity), typical for road cars and why they tend to favor power-dense chemistries like NMC.

By contrast, the Volvo L25 electric compact loader has a battery capacity of 40kWh and a maximum motor power of 36kW, so the battery is only required to discharge at a maximum of 0.9C, well below road-car expectations.

The same is true when considering the larger machines. The XCMG XE270E is a 27-tonne excavator with a battery capacity of 525kWh, but its motor is a paltry 140kW (~0.27C). In fact, research in the IDTechEx report shows that the vast majority of electric construction vehicles have a peak discharge requirement of less than 1C, with one-quarter of vehicles requiring less than 0.25C peak discharge.

A low peak discharge requirement can be fulfilled by lead-acid batteries, which is likely why it was explored in the early days of construction electrification. The European examples that used lead acid were mainly from the mid-2010s, when lithium-ion technologies were still scaling and were much more expensive than lead acid. However, these vehicles were seriously limited, with low endurance and slow recharge times. Lead acid was replaced with lithium-ion once the newer technology became more financially viable.

Both NMC and LFP offer the required performance for construction, coping with the peak discharge requirements and having high enough volumetric and gravimetric densities to fit in the machines. Speaking broadly, NMC tends to be a higher-performance battery than LFP, with better energy and power densities but coming at a premium. It would make sense then for the industry to select LFP. It offers all the needed performance while helping minimize the cost premium of building an electric vehicle – the number one priority for electric construction vehicles. So why does the European market mostly use NMC?

Choosing between NMC and LFP

The best explanation for why NMC dominates in Europe while LFP has taken off in China is a case of availability. Thus far, most of the construction-EV development in Europe has used battery-pack suppliers such as Northvolt, Forsee and Volta, and most of their products use NMC.

IDTechEx’s research finds that more than 75% of the offerings from European and North American pack manufacturers use NMC. These companies have been supplying a range of industries, including heavy-duty road vehicles such as buses and trucks. These vehicles require high peak power to deal with acceleration events, hills, etc. and are better suited to NMC. But with battery pricing being a key factor in the success of electric construction vehicles, increased LFP uptake is likely in the future.

Meanwhile, China already has a good supply of LFP solutions. As the country’s vehicle fleet has shifted to more electric vehicles, the domestic auto industry needed a more affordable solution that offered acceptable energy density (for an acceptable vehicle range). China’s electric construction industry has been able to build large batteries relatively quickly and deploy some huge machines, such as the already-referenced XCMG XE270E. By contrast, European and North American EV markets have focused on maximizing vehicle range, normally opting for the more expensive NMC chemistry, anticipating that their consumers will be more comfortable with the additional cost.

Unfortunately, there is not much data concerning which battery chemistries North American or APAC-based OEMs favor. This is mostly because OEMs in these regions are not as far along in their electrification journeys. North America is a prime example. Caterpillar and John Deere have made a recent push with electric construction vehicles showcased at Bauma 2022, CES 2023 and CONEXPO 2023. However, these machines are still some years away from production, and battery chemistries are yet to be confirmed. An educated guess, however, would suggest that Caterpillar likely will use NMC for reasons similar to those driving decisions at European OEMs.

Is sodium-ion a future candidate?

Another possible contender for the construction industry is sodium-ion, an emerging chemistry that does not have an established market yet. The key thing to know is that sodium-based solutions can be produced at lower costs than lithium ones, but they will not offer the same performance capabilities. In this respect, the batteries have the same trade-offs as LFP batteries.

The issue is that sodium-ion is not yet a scaled solution, so it is more expensive than both LFP and NMC while having worse performance. Sodium, therefore, does not make sense in the construction industry for the time being. However, if it can be scaled and then deliver the promised price reduction, sodium-ion could be a prime match for the needs of this nuanced market.

The construction EV industry is still nascent, with few vehicles in series production. However, if recent activity and announcements are to be believed, the number of machines available in the next few years is going to explode. In IDTechEx’s report, a 10-year CAGR of 37% is forecasted, with the electric construction machine industry growing to a value of US$150 billion in 2043. All this growth will give rise to significant battery demand. Whether the solution ends up being NMC, LFP or perhaps even Na-ion, the evolution of this industry is underway and accelerating fast.

Dr. James Jeffs, senior technology analyst at IDTechEx, wrote this research summary submitted to SAE Media. The "Electric Vehicles in Construction 2023-2043” report, including downloadable sample pages, can be accessed at www.IDTechEx.com/EVConstruction.