A deep dive into the carbon footprint of alternative fuel vehicles

Where your alternative fuel car is made as well as where and how it is driven significantly impacts its lifetime carbon emissions.

Together with Ansys, a developer of simulation software, we are creating a series of content about the technologies that make sustainable transportation possible.

Electric vehicles, hybrids, and hydrogen cars are greener alternatives to traditional vehicles powered by fossil fuels, but they still have an environmental impact. In this article, we take a closer look at their emissions examining their carbon footprint at the point of manufacturing as well as through their lifetime.

This article was based on a whitepaper by Tarun Tejpal, the Global Director for Transportation and Mobility at Ansys with significant editing and additions by Wevolver, science & technology journalist Sandrine Ceurstemont and journalist Mark Smith.

Electric vehicles

Overview

Electric cars are increasingly becoming a popular choice for drivers, where sales reached 2.1 million globally in 2019 with a 40% increase year on year1. Demand is rising dramatically2 which is being driven by several factors including consumers wanting to have less of an impact on the environment, financial incentives, and emission limits in major cities.

Manufacturing

While lauded as the simple answer to the escalating climate crisis, the green credentials of electric cars aren’t as straightforward as they may seem. Over the course of their entire lifecycle, they typically produce fewer emissions than cars that use fossil fuels, but the advantage varies in different stages of their lifetime. Polestar, Volvo’s electric vehicle spinoff, released a report3 outlining the carbon dioxide (CO2) emissions of its Polestar 2 vehicle and compared them to those of a conventional Volvo XC40 which has an internal combustion engine. Producing an electric car’s battery and other materials actually results in much higher CO2 emissions than the materials needed to manufacture the conventional vehicle. The electric Polestar 2 produced 24 tons compared to 14 tons for the Volvo XC40.

Another report4 found that 15 to 20 tons of carbon dioxide are emitted to produce a lithium-ion battery for an electric car with a 100 kWh capacity. Small electric cars such as the Nissan Leaf, which uses a battery with a capacity of 40 kWh or less, would therefore have far lower emissions. The energy mix used would however affect the calculation, where the report assumes that fossil fuels are used for 50 to 70 % of the energy.

Arguably the most high-profile manufacturer of alternative fuel vehicles is Tesla. Despite its reputation as a groundbreaking producer of electric vehicles, trying to ascertain the company’s impact on the environment has proven difficult. According to a study5 by asset-management company Arabesque, Tesla lags behind rivals such as Ford and General Motors in disclosing its precise carbon footprint and environmental targets. Elon Musk’s company continues to deploy green technology such as the solar panels which adorn the roof of the Gigafactory in Nevada6, but some observers believe its continued rapid expansion into China, coupled with the establishment of a new car plant in India itself, could lead to a rise in its overall carbon footprint7. This is because both countries still rely a great deal on fossil fuels such as coal, which will often be used as primary power sources to power up electric vehicles which are sold there.

Manufacturing emissions are set to decrease as renewable sources are increasingly used to generate the electricity needed. Battery production facilities are also becoming larger, which is making them more efficient when considering each battery produced and therefore helping to reduce their environmental impact.

The raw materials used to make electric car batteries also need to be considered since they have an environmental footprint. Lithium, cobalt, nickel, and manganese are the main metals typically used, where emissions from extraction during mining and reprocessing need to be cut back. According to the authors of a recent report8, more information is needed about this part of the process to help make it more sustainable. As batteries become higher-density, their nickel content is expected to increase while cobalt is being phased out due to issues with supply. Nickel could therefore become in high demand.

At the same time, recycling metals from used batteries can help reduce the need for raw materials. Although cobalt and nickel are widely recycled in Europe, lithium is lagging behind since it is expensive to repurpose and cheap to obtain as a raw material. Collecting used batteries can also be a barrier where better efforts are needed to retrieve them after use.

On the road

During their use, electric vehicles offer clear environmental benefits, particularly in regard to producing no exhaust. However, the scale of their impact depends on the source of energy used to charge the vehicle’s batteries. For the Polestar 2, emissions varied from 23 tons over the course of its life when it was using electricity sourced from a global energy mix - primary energy sources which could include both renewables and non-renewables - to 0.4 tons with the sole use of electricity sourced from wind. In comparison, the Volvo XC40 – which has a conventional engine - produced 41 tons.

As the demand for electric vehicles grows, it will be critical for renewable sources such as solar, wind and nuclear power to be adopted more widely for electricity production. Currently, worldwide electricity production is dominantly produced by coal, gas and hydro but the mix of energy sources varies widely from country to country which can have a significant impact on the lifetime carbon emissions of electric cars.

In Sweden and France, for example, where electricity is primarily generated from nuclear energy and renewables, the lifetime emissions of electric cars are about 70% lower than traditional cars9. In the UK, lifetime emissions are about 30% lower than for a conventional vehicle as less renewable energy sources are used. Despite discrepancies, there is generally an overall environmental benefit to driving an electric vehicle in most countries. Poland is an exception to this rule where coal is still the main source of electricity and so any environmental gains made by the use of EV’s become obsolete. As nations transition to using more renewable energy, the outlook should increasingly be more favorable for electric cars compared to traditional vehicles.

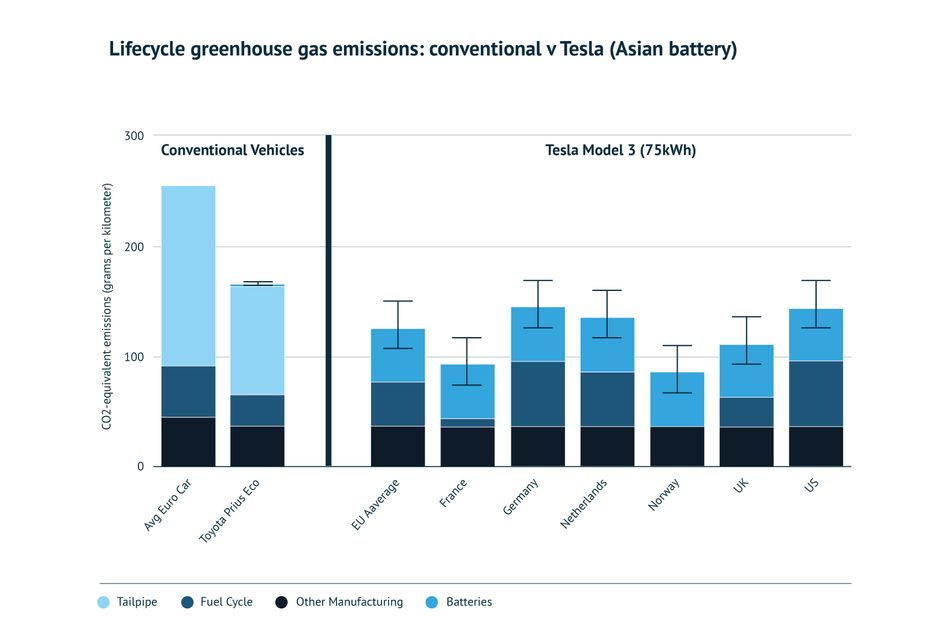

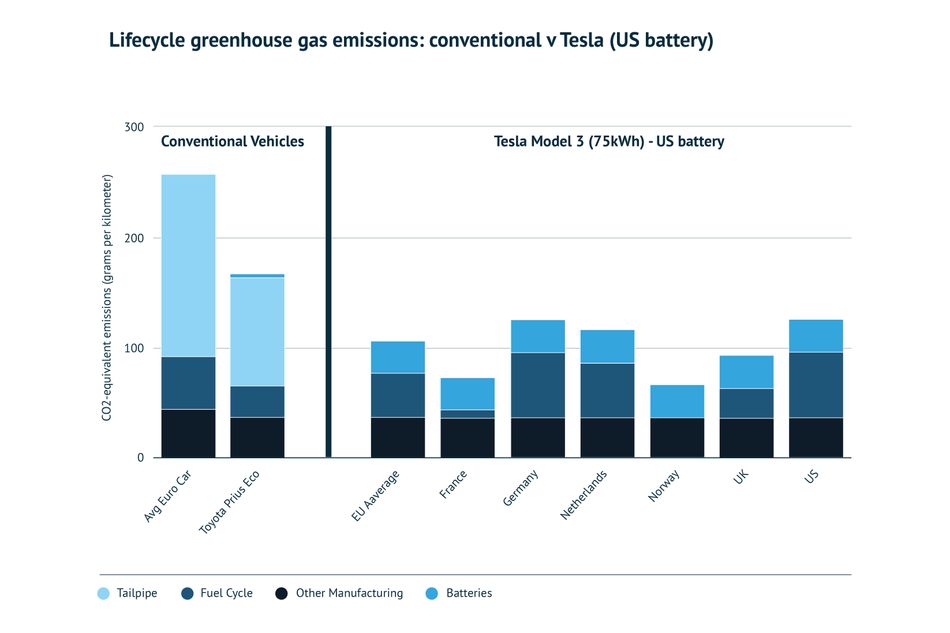

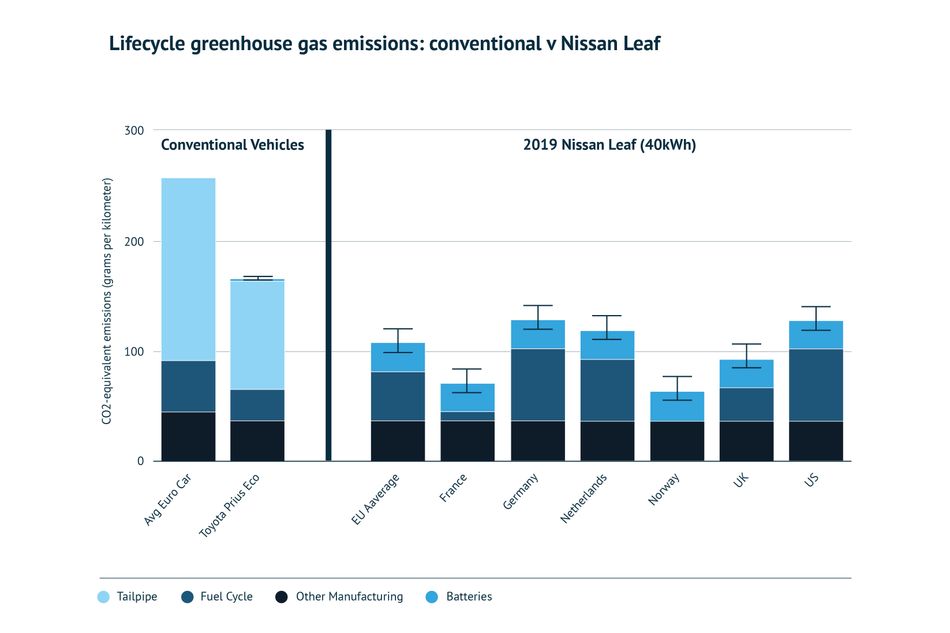

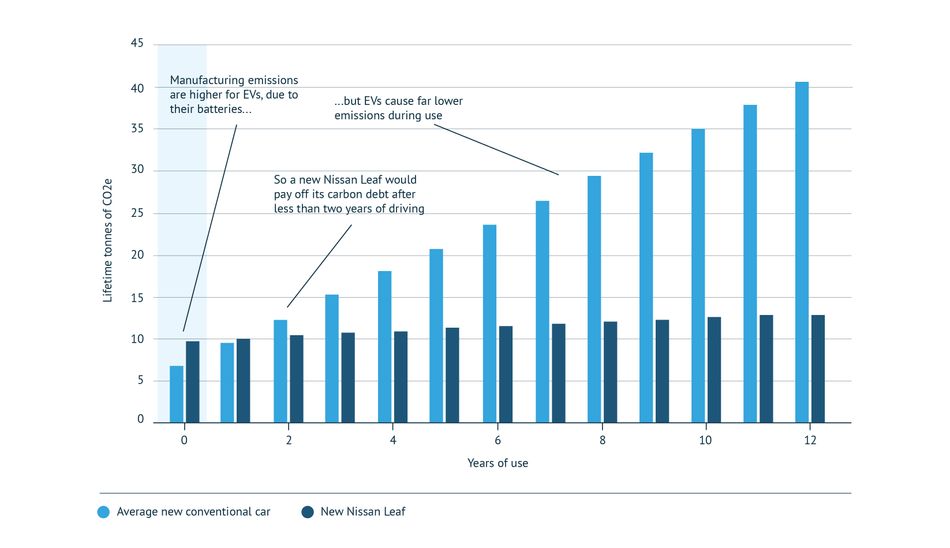

In the graph below, greenhouse gas emissions over a vehicle’s lifetime are shown, where a conventional vehicle is compared to the Nissan Leaf electric car. Emissions from battery production are shown in light blue, with error bars to account for uncertainties in data. The fuel cycle - which includes oil production, transport, refining, and electricity generation - is shown in mid blue, while other manufacturing emissions are shown in dark blue. Although a conventional vehicle has higher emissions overall, the impact that battery manufacturing has on an electric vehicle footprint is clear. Greener battery production must be increased in order to reduce the environmental impact of electric car manufacturing.

Despite the significant impact of manufacturing, the emissions of electric cars quickly level off. It is estimated that the high cost of battery production is paid off after about 2 years of use when a car is charged using a mix of energy sources, dropping to 1.5 years when renewables are solely used10.

Plug-in hybrid vehicles

Overview

Similarly, global demand for plug-in hybrid vehicles (PHEVs) is also growing. They are often the go-to choice for people who aren’t ready to transition to a fully electric car for several reasons such as their high price, a lack of charging infrastructure, and range anxiety.

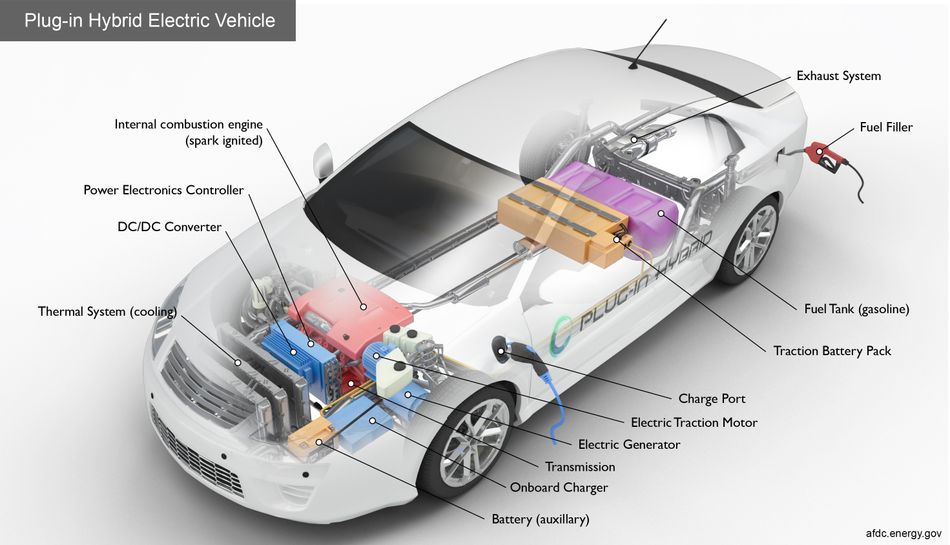

PHEVs use batteries to power an electric motor combined with another fuel, such as petrol, to power an internal combustion engine (ICE). The hybrid will then runs on electric power until the battery is almost drained, and then the ICE takes over. Since plug-in hybrids can also function using fuel, they are able to bridge some of these concerns by providing more flexibility while also providing some environmental benefits.

Manufacturing

During production, hybrids are less polluting than electric cars. Overall CO2 emissions are about 1.4 tonnes lower than those emitted when an electric car is built11, which is largely down to their lower capacity battery. In the future, construction emissions from these two types of cars could be more similar as the battery production process is improved and greener sources of energy are used to produce electricity.

On the road

A hybrid’s impact on the climate largely depends on how it is used. If the battery is always charged and the car is only required for short trips, then emissions should be minimal. On the other hand, if the battery is often low, the internal combustion engine will be used most of the time. As a result, emissions can be even higher than conventional cars since the engines of plug-in hybrids have a low power output for their weight.

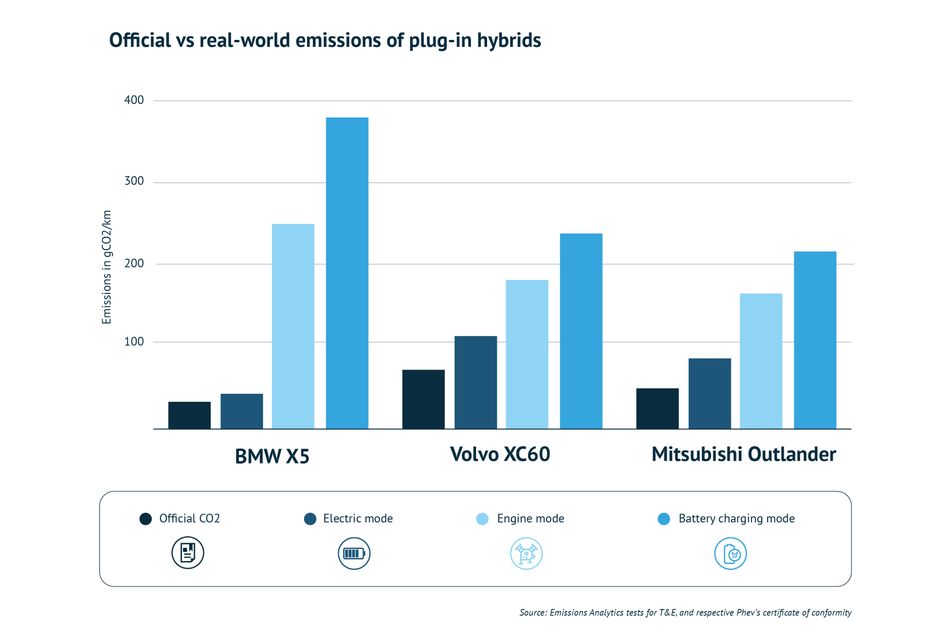

A recent report10 has shown that real-world CO2 emissions of hybrids are over two and a half more than what is predicted in laboratory tests. The main reasons are that people often don’t charge their cars fully, meaning they have to rely on the ICE partway into a journey, and the car does not actually drive using only the battery and electric motor even when in zero-emission mode. The ICE may also be needed if the heating or air conditioner are turned on, if windows need to be defogged or if electric motors can’t provide the amount of power needed, for example.

Consequently, the emissions of plug-in hybrids during usage are typically much closer to those of a traditional fossil-fuel-powered vehicle than an electric one. A hybrid produced in 2020 is expected to emit about 28 tonnes of CO2 over the course of its lifetime on the road compared to about 39 tonnes for a conventional car with an internal combustion engine10. An electric car model from 2020, however, will emit in the ballpark of 3.8 tonnes of CO2.

Hydrogen fuel cell cars

Overview

Hydrogen fuel cell cars are also touted as an attractive option when it comes to sustainability. In these types of vehicles, the power is generated by chemical reactions between hydrogen and oxygen rather than being stored in a battery which has to be powered up by an external source. At its most basic level, the technology combines hydrogen and oxygen to produce water and electricity, with the water vapor and warm air being its only waste products, which are then expelled via the car’s exhaust.

They also have a higher driving range than electric vehicles, where they can typically cover over 300 miles on a tank of gas compared to just over 100 miles on a battery charge for an electric car. Refueling is also quick, where a car’s tank can be topped up in about 3 to 5 minutes. However, there are also disadvantages. Hydrogen cars are far less energy-efficient than electric vehicles, as only up to 35% of the energy produced is transferred to the wheels of the car compared to between 70% and 80% for electric vehicles. That means that two to three times more energy is needed to power them.

This matters because producing the hydrogen cells to power these vehicles can still leave a carbon footprint. The cells need electricity to be converted to hydrogen. The gas then has to be compressed, chilled, and transported.

Production and manufacturing

Hydrogen production is also typically not sustainable. Steam methane reformation, for example, which is used to produce over 95% of hydrogen11, requires fossil fuels where natural gas reacts with steam. The process uses methane to react with steam under pressure to produce hydrogen, carbon monoxide, and a small amount of carbon dioxide.

A study conducted in the US12 found that to produce one kilogram of hydrogen gas, about 9 kilograms of CO2 were typically emitted. Hydrogen can also be obtained from water using a more environmentally friendly process called electrolysis but it’s less economical and therefore not attractive for commercial production.

New innovations could change that though. An Israeli start-up called H2Pro has developed a two-step process for electrolysis13 that could greatly reduce production costs. It should also increase the energy efficiency of the hydrogen produced by 20% to 25%14.

On the road

Hydrogen fuel cell vehicles do not produce harmful emissions, only water vapor, and warm air. This means they could be well-suited for long-distance transportation, where zero emissions during use can help with decarbonization when carrying heavy goods over vast distances. Being able to refuel quickly and not carry a heavy battery is also beneficial for long trips. Although manufacturers such as Hyundai and Toyota have introduced hydrogen-powered trucks for commercial routes, the drawback has been a lack of fueling stations. Europe and Japan, for example, have much denser hydrogen infrastructure compared to the US where the high implementation cost has been a barrier. However, since commercial fleets typically travel on set routes and wouldn’t need to fuel up often, it would be feasible to set up stations about 500 miles apart along highways for long-haul use.

Overview

The three types of vehicles all vying to take the place of ICE vehicles all have very different strengths and weaknesses. With major companies like Tesla behind them, EVs are touted as the long-term replacement for ICE vehicles. While like-for-like they have a reduced direct impact on the environment and are cheaper to run compared to the latter, they still suffer from a comparative lack of range.

Sitting somewhere between EV and ICE, hybrid vehicles combine electricity with a traditional combustion engine. This makes them more environmentally friendly than ICE vehicles, while also offsetting some of the practical, mileage concerns of EVs. But by their very nature, they still rely at least partly on fossil fuels, arguably making them only a partial solution to the current environmental predicament.

Still very much the new technology on the block, hydrogen vehicles do not give off any emissions at all, save for some water vapor and warm air, but are not as efficient as the other two types of vehicles. They also lack the wider fueling infrastructure of the alternatives too, even in the US.

The fly in the ointment for all three though, is that by and large, all rely on primary fuel sources which can be fossil fuels, whether it is the hydrogen cell production process or the process of producing the electricity used to charge EV and hybrid batteries. The carbon footprint of all three is potentially greater still when factors such as battery and vehicle production, as well as manufacturing and transportation of parts, are considered.

Simulation use in vehicle design key to reaching decarbonization

Alternative fuel vehicles have a significant carbon footprint resulting from manufacturing processes or hydrogen production and charging when they are in use for electric vehicles and hybrids. However, they are still far greener than conventional vehicles. As more countries switch to renewable energy sources to generate electricity, the environmental impact of electric and hybrid vehicles will continue to decrease.

As described in our foundation article of the series, the fastest way to decarbonize the transport industry is through shifts in the design and manufacture of vehicles with increased use of simulation technology to iterate faster and expedite innovation. Increased use of generative design and additive manufacturing, better battery technology, and more efficient modes of generating electricity can all be achieved with the increased use of simulation.

About the sponsor: Ansys

Ansys provides engineering simulation software used to predict how product designs will behave in real-world environments. Founded in 1970, Ansys employs more than 4,400 professionals, many of whom are expert M.S. and Ph.D.-level engineers in finite element analysis, computational fluid dynamics, electronics, semiconductors, embedded software, and design optimization.

References

- International Energy Agency – Global EV Outlook, 2020

- Bloomberg NEF – Electric Vehicle Outlook, 2019

- Autocar – Analysis: Polestar lifts the lid on lifetime EV emissions, 28 September 2020

- Swedish Environmental Research Institute – Lithium-Ion Vehicle Battery Production, 2019

- Forbes – How green is Tesla really? 13 May 2021

- Teslarati – Tesla Gigafactory Nevada ramps installation of new rooftop solar panels, October 15 2020

- Bloomberg – China and India will raise Tesla carbon emissions, February 17 2021

- BBC – Electric car emissions myth ‘busted’, 23 March 2020

- The International Council of Clean Transportation – Effects of battery manufacturing on electric vehicle life-cycle greenhouse gas emissions, February 2018

- C40 Knowledge Hub – How to drive electric vehicle uptake in your city, March 2019

- C40 Knowledge Hub – How to build an electric vehicle city: deploying charging infrastructure, March 2019

- Nature Scientific Reports – CO2 Mitigation Potential of Plug-In Hybrid Electric Vehicles larger than expected

- Transport & Environment – UK briefing: The plug-in hybrid con, September 2020

- Forbes – Estimating the Carbon Footprint of Hydrogen Production, June 2020

Graphs adapted from: Factcheck: How electric vehicles help to tackle climate change, May 13 2019.