A spectrum of spikes allows this novel electronic skin to sense touch like we do

Using a highly-scalable approach to creating dense sensor networks, yet requiring only a pair of address lines, these researchers have taken inspiration from the human somatosensory system for a rapid-response sensitive sense of electronic touch.

Two prototype position-encoded spike spectrum (PESS) sensors, one showing its ability to flex and confirm to non-linear surfaces, have been proven experimentally.

This article was discussed in our Next Byte podcast.

The full article will continue below.

Electronic skin, which weaves technology into a flexible and stretchable substrate designed to mimic human skin, offers potential for everything from highly-dexterous robotics to sensory-feedback prosthetics, health monitoring, medical implants, haptics, and more. Current implementations, however, often suffer from high power draw and slow response times.

A new approach, based on what a team of researchers at the Pohang University of Science and Technology (POSTECH) and the Ulsan National Institute of Science and Technology (UNIST) has termed position-encoded spike spectrum (PESS), could change that — offering a high-resolution, high-sensitivity artificial tactile system which manages to also be easy to manufacture at scale.

Spiking sensors

The concept is borrowed from biology: The human somatosensory system offers event-driven spike generation, with parallel processing allowing sensations to be felt without delay. While rival approaches aimed at mimicking the same process electronically exist, they center around analog-to-digital converters (ADCs) which limit their resolution and add bulk.

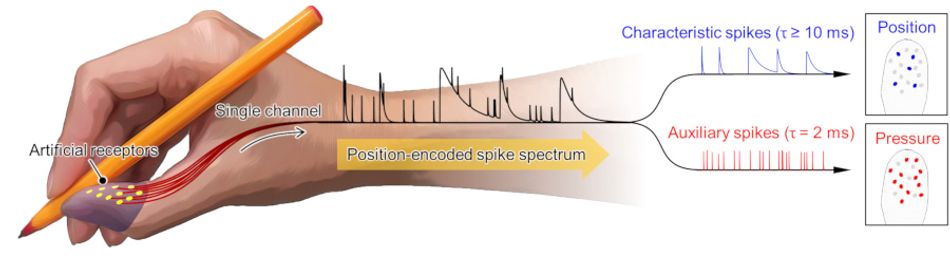

What first author Taeyeong Kim and colleagues have developed, by contrast, is a sensory system offering much the same capabilities as the human sense of touch. A mixed ion-electron conductor (MIEC) hosts artificial receptors designed with varying ion relaxation times — turning touch into a spectrum of spike signals, rather than a single reading.

This spike spectrum is key to the responsiveness of the system itself: The relaxation time of each spike can be decoded in real time, its creators claim, to identify exactly where and how the skin is being touched. The overall delay was measured at of 2ms for the auxiliary spikes, which carry pressure information, and 10ms for the characteristic spikes, which offer position.

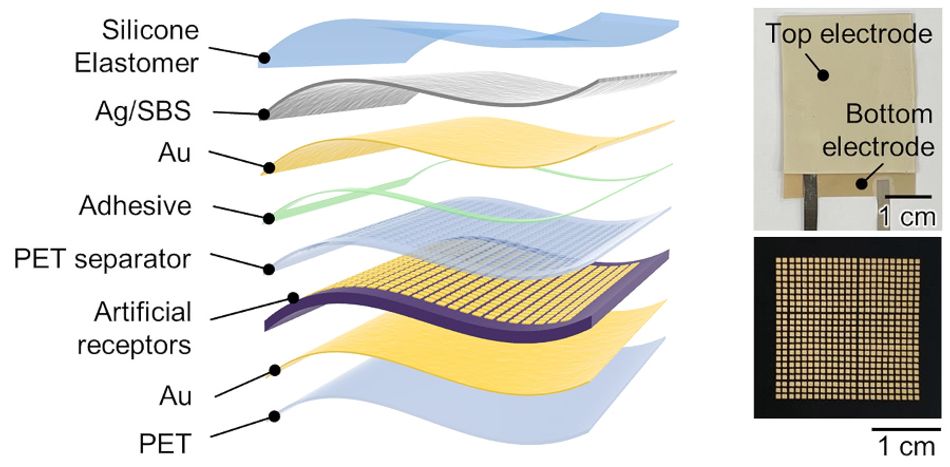

At the same time, the sensor system is surprisingly simple. The prototype was produced using a combination of the MIEC film and PEDOT:PSS as a conducting polymer, applied via spray coating through a patterned stencil mask — each hole in the mask corresponding to an individual receptor. Layers of silver and gold act as electrodes in the system.

Touchable proof

To prove the concept, the team created a compact prototype measuring 2×2cm (around 0.8×0.8") and featuring an impressive 529 individual receptors. Despite this, it required only two signal addressing lines — a major advantage, its creators claim, over alternatives which rely on time-division multiple access (TMDA) addressing, and a closer analog to the highly-parallel human somatosensory system.

As the prototype was touched, the resulting spikes were analyzed by a decoding algorithm in just 2ms. The algorithm, in turn, offers inferred tactile information based on analysis of the characteristic and auxiliary spikes: Position, size, rough shape, and even pressure down to 1.5kPa, all reported with high accuracy.

In further testing, the team showcased the skin’s ability to detect two-dimensional movement, in the form of sensing letters drawn on its surface, and of providing real-time feedback when applied to a robot arm. In these tests, the robot arm was given the task of grasping a metal sphere, rotating, allowing the ball to fall to the bottom of the grip, then shaking it repeatedly — detecting slippage through the PESS system and tightening its grip instantly in order to prevent the ball from being dropped.

Further work

There’s the potential for improvement, too. The team suggests that the application of “machine learning-based decoding” could allow the PESS system to determine more complicated shapes than is possible using the existing algorithm, while experimental results suggest the possibility of extending the system to omni-directional tactile perception.

“Converting the external stimuli into spike signals and processing them is a groundbreaking idea that mimics how the human nervous system processes information,” says Sung-Phil Kim, UNIST professor and co-corresponding author of the paper detailing the breakthrough.

“If a new AI model is developed using this spike information encoding method, robot tactile intelligence can be further developed and effectively applied to next-generation semiconductor technologies such as neuromorphic chips.”

A sensor variant which integrates four separate sensing systems into a single device, meanwhile, boosts the stationary spatial resolution to 80 receptors per square centimeter (80/cm2) and for dynamic sensing to 132/cm2 — a figure which the team suggests could be increased still further with improvements to measurement equipment and the sensor’s stencil layer.

One issue standing in the way of production use, however, is in creating a PEDOT:PSS layer of reliable and repeatable thickness. “Unfortunately,” the team admits, “delicate thickness control of the PEDOT:PSS coating on the target positions for the characteristic receptors was not achieved yet in this study.”

The team’s work has been published in the journal Science Robotics under closed-access terms.

Reference

Taeyeong Kim, Jaehun Kim, Insang You, Joosung Oh, Sung-Phil Kim, and Unyong Jeong: Dynamic tactility by position-encoded spike spectrum, Science Robotics Vol. 7 Iss. 63. DOI 10.1126/scirobotics.abl5761.