Augmenting human endurance with carbon fiber suits

Carbon fiber fashion aims to assist humans to endure extreme weather and activities.

The High-Temperature Carbon-Fiber 3D Printing Challenge invited engineers and designers to submit ideas on how to leverage cutting-edge materials from Mitsubishi Chemical Advanced Materials. Participants in the challenge were asked to incorporate the strength and properties of the KyronMax® carbon-fiber 3D printing filament with the flexibility and sustainability of 3D printing in their design.

We are composing a series of articles featuring the finalists and winners of the challenge.

In this article we showcase the work of Robin Kocher from Human Earth Industries an upcoming player in the micro-engineered suits domain.

Suits for the future

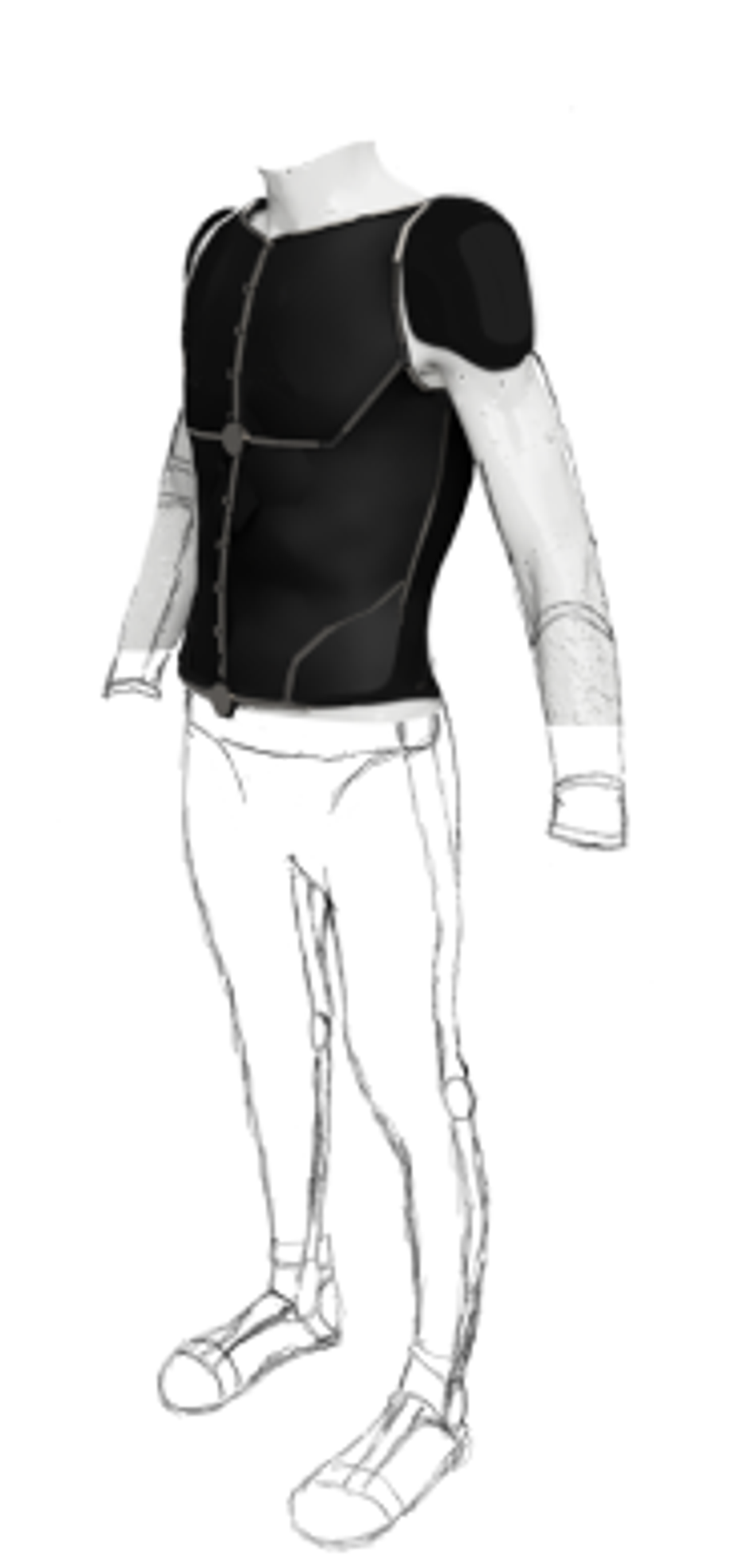

The specialized suits designed by Kocher, aims to protect against harsh weather conditions. The suits are primarily intended for providing support during disaster relief, extreme sports, and various outdoor activities. They have multiple layers which can be customized based on the activity.

"We visualize the company in two parts. The primary focus behind Human Earth Industries is facilitating a change in society, imparting a sense of awareness in people regarding the 17 sustainable development goals, and spreading the word of change. The second part is the engineering aspect of it, where we aim to revolutionize the fashion technology industry," said Kocher. The idea for developing the suits was first conceptualized when Robin was still a student. As a gaming enthusiast, he wondered how the advanced suits in video games would be like in the real world. "My interest in video games and science fiction helped me design the fabrics for the prototype. The ideas stemmed mainly from publicly available research," he added.

Sustainability is the top priority

The suit has a customizable design where one can alter various functionalities. It would be possible to insert a layer that can measure the heart rate, blood oxygen, and ambient conditions. Additionally, another layer with a pathfinder module and smart ventilation (heating and cooling), primarily geared towards disaster relief activities would also be incorporated. "The material that we use for the suits are not particularly environmentally friendly. I want to make products that can be used for a long time and the suits are designed to last a lifetime. I want people to pass on the suits to the next generations. This is one of my approaches to sustainability. The components would be made from bio-compostable products in the future," said Kocher.

Diversifying functionalities with carbon-fiber

The early-stage startup wants to engineer their specialized suits for various operations. For instance, Robin has deep-dived into the topic and has identified the risks involved for horseback riders.

He is developing a prototype of a safety vest with a carbon fiber layer that protects the riders from potentially severe falls. This vest can also be purposed for other activities such as skiing and motorbiking.

MCAM’s Growth Garage challenge pushed design ideation

When we asked Robin, what the most challenging criteria of the submission was, he said: "The criteria pertaining to the technical requirements was quite impressive, especially when we had to work with high-temperature requirements. When we started designing the product, we had to make sure that it satisfied the sustainability as well the high temperature criterion. It helped me visualize the incorporation of the carbon fiber layer in the specialized suits. The challenge was quite an enjoyable experience for me."

Kocher is impressed by Mitsubishi Chemical’s focus on sustainability and conscientious practices. It was also one of the reasons that compelled him to enter the challenge. "As a self-financed startup, it is always nice to receive support from organizations that can help us take our product to the next level, in terms of design, manufacturing and product upgrades. I would love to take part in the new challenges and create an awareness of thriving in the industry by consciously contributing back to the environment and society," he said.

Follow Growth Garage's LinkedIn page for more interesting stories about 3D printing entrepreneurs in various fields.

The Composite Engineering Challenge

We are inviting innovators, entrepreneurs, and early adopters at universities, (pre-) startups, and scaleups that need fiber-reinforced composites to realize their prototype, part, product, or application.

We welcome projects, programs, and companies in the field of new mobility (EV, e-motor, battery casing, etc.), autonomous (delivery) vehicles, people movers, robotics, aerospace, space, bicycles, UAV, AAV, bionics (wheelchairs, exoskeletons, prosthetics), alternative energy (production, storage, transport), self-sensing or self-healing, sport & leisure, alternative (low carbon footprint) fibers and more!

The winning entry will be rewarded with a partnership with Growth Garage, Business Incubator of the MCG Advanced Materials Division.

This partnership package is valued at $25,000 and will be tailored to the winning team’s needs according to their current business and product development stage.

READ MORE ABOUT THE CHALLENGE HERE.

Key Dates

|