Chipping in on the SBC Supply Chain - predictions for the future.

Article #4 Electronics Innovation Series. Alternative SBC’s and customer-orientated manufacturing will ease supply chain conditions.

OKdo is a component supplier and electronics consulting company based in the UK. They are on a mission to inspire and enable customers to generate new ideas and turn them into commercial reality.

The state of the semiconductor sector

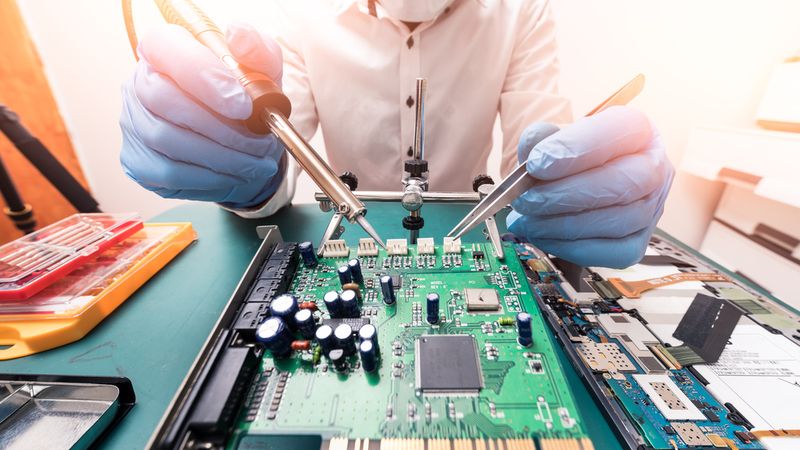

Semi-conductor chips are so important across all industries. They are the key component in electronic devices, inside everything from cars to appliances to factory equipment. For OKdo, all our products will contain these types of components as we specialise in hardware for computing power and connected devices.

Many of our component manufacturing suppliers and industry partners continue to be in allocation, which means there is no free stock currently and prices are higher than normal. We must give at least 12–18-month forward forecasts to those suppliers to get in the queue to receive stock, and for new purchases from the main silicon brands, we’re often quoted lead times far exceeding 12 months, extending well into 2023.

However, we are seeing some indications of change. It has been announced just this week the UK is officially in recession, with rising energy prices pushing inflation above 13%. The picture is similar in most countries around the world. Consumer demand is generally in decline, due to rising costs of living and record interest rates, increasing loan repayments. As consumer demand falls, we would expect ramifications across manufacturing demand for products which require semi-conductors, resulting in greater availability of components early in 2023.

What’s caused the supply constraints over the last 18 months?

The events of last 2 years have meant global supply chains have been hit extremely hard. At the start of the pandemic in 2020, we saw a huge demand increase for semi-conductors due to the global pandemic. This demand stemmed from increased demand for consumer electronics, home computing, and the automotive industry, which has been increasing electrifying.

Automotive production and manufacturing lines all over the world halted, not only because of the lack of supply of chips, but because of labour shortages due to the pandemic. Uncertainty in the market driven by geo-politics, extreme weather events, logistics capacity shortages only compounded the affect. It was evident quickly that semi-conductor suppliers could not cope with even a small increase in demand.

70% of the global foundries are concentrated across 2 or 3 locations and struggled to increase capacity and required huge billion-dollar investments to do so. This exposed a weakness in the supply chain and through years of optimisation of “just in time” manufacturing, no-one seemed to be prepared to handle extreme events. As demand outstripped supply, price’s increased, shortage queues grew and margin-driven customer allocations (with all previous commitments null and void) became the norm.

What do you think will be next – when will people start to see a change?

Over the last 12 months, we’ve seen global powers of USA and Europe put the semi-conductor supply chain issues at the top of the political agenda. Foundries have invested Billions on programs of increasing capacity and strengthening resilience in the supply chain by near-shoring new facilities in the US and others in Europe. This effort could easily be in vain, impacted by any number of geo-political issues emerging right now, so time will tell.

What can OKdo offer as a solution to customers who are struggling to find supply of SBCs or other connected devices, or who need a reliable manufacturing and design partner?

At OKdo, we offer the following key services to our customers and ecosystem partners to cover the whole product life cycle through to end-customer delivery:

- Design Stage: component selection and rapid PCB/PCBA prototype and EVT

- NPI/Proto/PVT/Ramp Up: agile manufacturing in global locations

- Mass Production: scale up volume in global locations, with cost optimisation by OKdo supply chain and procurement professionals and CMs

- Box Build/Kitting: to get the product customer ready, fully assembled or added value options to end-customers

- Global warehousing and distribution: via a network of RS Group warehouses and OKdo managed 3PLs we offer drop ship or local distribution services to the end-user as well as global inventory availability and fast delivery options.

We have a resilient supply chain and an agile design and manufacturing offer for our customers. Our internal supply chain expertise can help our partners navigate the enormous supply chain risks and challenges to the macro-economic climate today. Manufacturing today is entirely different from a few years ago, and we are ensuring we have coverage, capacity, and supply chain plans to manage uncertainty with our world-class team, and partners.

Our manufacturing partners have world-class procurement and sourcing teams, ensuring continuity of supply of components to keep our promises to our customers. We have invested in internal resources within OKdo in procurement and supply chain to work alongside our CMs to ensure we negotiate and procure critical components to minimise risk of supply chain disruption for our customers.

Our manufacturing services are based on the below 6 principles to benefit our ecosystem partners and to drive meaningful revenue growth for OKdo;

- Customer Orientated: The OKdo Technology, Manufacturing and Procurement Team are dedicated to our customers every step of their design to manufacture journey, fully equipped at a global and regional level for speed of execution and driving value

- The Right Choice of CMs: Global contract manufacturing (CM) partnerships offering regional/local manufacturing capability, with a strong account management team with a range of languages to suit OKdo and our customers

- ESG & Sustainability: Our CMs have sustainability and ESG at the heart of their values and supply chain; aligned to the OKdo ethos and ethics

- Living with Supply Chain Risk: Our CMs aid our endeavour for a flexible and agile supply chain, with global distribution options including direct to customer at a global and regional level and local buffer stocks

- Smart Procurement: Strategic component partnerships directly managed, with multiple procurement approaches from direct through to using Letters of Authority to CMs to purchase turnkey

- Equitable Relationships: Fair and balanced commercial frameworks for all parties based on trust and respect.

Is there any alternative SBCs we can offer our customers?

We know there has been a shortage of single board computers due to the semi-conductor market. However, we have been working on a solution to this.

We’re introducing a new product range called OKdo Rock which has been designed around component availability, with the customer in mind in terms of ability and capability and we’ve put in safeguards across the supply chain to ensure continuity of supply.

Rock is an advanced SBC designed to empower engineers, students, and developers all around the world to create digital making by providing open, free, versatile hardware. What’s more, the ROCK range of boards can be customised. The ability to depopulate SBCs without compromising their integrity brings huge financial and environmental benefits, allowing professional design engineers to leverage cutting-edge technology for developing high-volume end products that meet their exact needs and work towards reducing e-waste. This position it as an important play to our industrial customers.

Visit us on our website https://www.okdo.com/solutions to find out more.

Find Sarah Fawcett at linkedin.com/SarahFawcett.