Designing Medical Devices for Real-Life: An interview with Molex Printed Circuit Solutions

Article #5 of Improving Lives with Digital Healthcare Series: Intelligent software, wireless connectivity systems along with developments in flexible circuits have enabled electronic part manufacturers to provide OEMs the support required to implement better medical solutions.

This is the fifth article in an 8-part series featuring articles on Improving Lives with Digital Healthcare. The series focuses on electronic systems that enable innovation in the healthcare industry. This series is sponsored by Mouser Electronics. Through the sponsorship, Mouser Electronics shares its passion for technologies that enable smarter and connected applications.

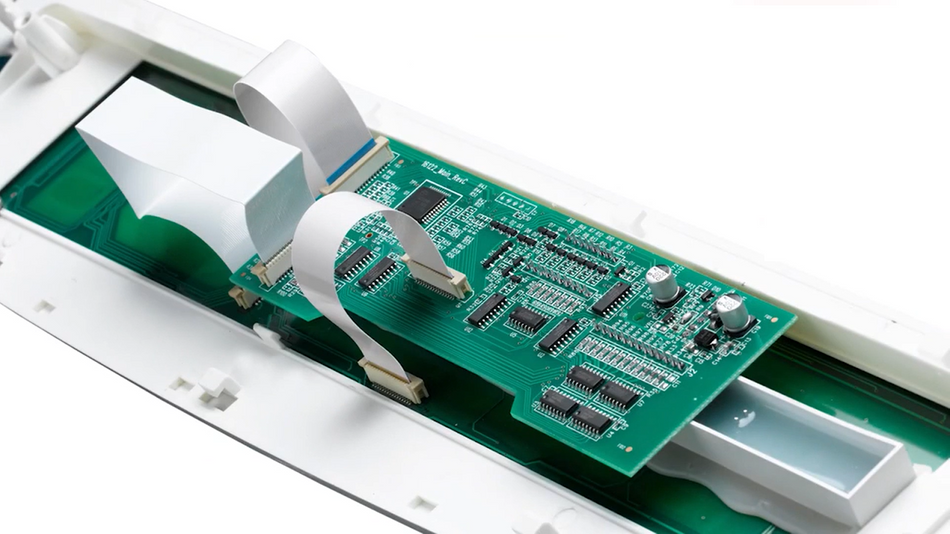

Printed Circuit Boards (PCBs) are traditionally made by depositing copper tracks on a rigid and non-conductive substrate. Their primary goal is to carry electricity from one point to another and provide mechanical support to the various electronic components placed over them.

Usage of flexible materials for making PCBs has resulted in the development of printed electronics, a field that finds its applications extensively in biomedical electronics and wearable devices. In this insightful and informative webchat, Mike Deppe, Vice President and General Manager at Molex’s Printed Circuit Business (PCS) business unit, discusses relevant trends and opportunities driving new solutions for medical wearables applications. The webchat was hosted in May 2021 by Glen Capek, Director of Multimedia Communications at Molex.

Glen Capek: Mike, please tell the audience a bit about the PCS team, and how printed circuits are used in medical devices and wearable technologies. What sparked the developments in flexible circuits?

Mike Deppe: The PCS team has been involved with medical wearables for well over 25 years. PCS originally started supporting its customers with user interface keypads. They also developed the control panels with flexible printed circuit assemblies as well. That has ultimately transformed our capabilities to be able to design and manufacture highly complicated electronics onto flexible circuitry that the patient can wear, that are used in wearable devices today.

Glen Capek: When you talk about medical wearables, you are talking about a piece of technology that the patient is wearing. Please tell us more about that.

Mike Deppe: Certainly. Consider the following example. There could be sensors or circuitry attached to the body to pick up different vital signs such as your heart rate, body temperature, oxygen levels, and such. It would be ideal if this circuitry could employ wireless monitoring. We can have different specific medical applications, such as monitoring the body’s temperature during surgery to help keep the patient stabilized.

Glen Capek: During the pandemic, we have witnessed first-hand the reality of people talking directly to their doctors over the computer and similar devices to avoid the necessity of visiting face-to-face. What are we doing in the telehealth space?

Mike Deppe: COVID-19 has had a tremendous impact in the medical space, especially concerning telehealth. This is because patients have found it extremely difficult to have live visits with their personal doctors and healthcare providers. To alleviate and mitigate this issue, PCS attempts to modify how we interact with healthcare providers.

We capture more patient data by relying more heavily on medical wearables or other related devices. The patient and the doctor may exchange this data, and each can better monitor the patient’s conditions. This applies whether they are vital signs or other information that may lead to better preventative maintenance. Connected healthcare allows the patient to provide that data to their healthcare provider in an ongoing and continuous manner. This ultimately helps everyone involved make better decisions while doing all this remotely.

Glen Capek: What are some trends that we are seeing in this part of the industry?

Mike Deppe: There are several trends identified around patient comfort. Patient comfort may include ensuring that the typically bulky and rigid electronics are designed to be more comfortably applied to the patient. Lowering mass, increasing flexibility, extending battery life, and, reducing power consumption, are some essential criteria.

The healthcare sector is also seeing noticeable changes in patient compliance. Patient compliance describes the degree to which a patient correctly follows medical advice. It most commonly refers to medication or drug compliance, but it can also apply to other situations such as medical device use, self-care, self-directed exercises, or therapy sessions. It is desired by all that patients or healthcare users follow the adherence guidance provided by the medical professionals. This is to ensure that the patient is receiving the highest quality care possible. Connected healthcare solutions help healthcare professionals track and observe precisely how well their patients are complying and following the medical recommendations.

Finally, another trend in the industry is related to software integration. Medical devices have traditionally been mechanical hardware. However, with more and more electronics being incorporated and added to these devices, it requires more software integration.

Glen Capek: How is Molex PCS responding to some of these mega software trends?

Mike Deppe: Molex PCS is in a position to provide both the hardware and the software. With our internal mechanical engineering and electrical engineering teams, Molex PCS can offer a great advantage to our customers by integrating and supporting both the hardware and software elements across the board. It’s the team that we have within PCS that differentiates and makes the difference.

To fully support our customers’ needs from a design aspect, our processing capabilities, and our global manufacturing footprint, which allows us to deliver competitive solutions. Having all those facets co-located within one business unit to support our customers’ custom and modified medical needs will enable us to separate and differentiate within the market.

Glen Capek: Okay, so we’ve talked a lot about medical uses for PCS products. Where else are they used?

Mike Deppe: Molex PCS products can be applied in various markets, apart from the medical sector. These additional markets also include applications within the automotive, home appliance, industrial, and commercial space. Molex PCS realizes many different opportunities, such as supporting user interfaces, control panels, and flexible printed circuit assemblies (FPCAs).

Electronic solutions from Molex are available on Mouser Electronics official website. To access trending articles, white papers, videos, case studies, podcasts, and more about electronics and connectivity, visit Mouser-Molex content hub.

Conclusion

To sum it up, the key trends in medical technology and healthcare are all based on increasing patient comfort, compliance, and making the treatment more effective. Improved applications of printed circuits, wireless communication, sensing, and electronic systems in general, will give rise to developments in medical devices, making them smaller, accurate, comfortable, and affordable.

This article is based on an interview initially published by Mouser and Molex in an e-magazine. It has been substantially edited by the Wevolver team and Electrical Engineer Ravi Y Rao. It's the fifth article from the Improving Lives with Digital Healthcare Series. Future articles will introduce readers to some more interesting applications of electronics in healthcare.

Introductory article covered the fundamentals of biomedical instruments and the ways in which digitizing them is transforming healthcare.

Article 1 explored the design challenges in Consumer and Medical wearables. It showcased how technologies once limited to hospitals are now made available to everyone for monitoring personal health.

Article 2 was focused on the present state of robotic surgery. It explained how advancements in robotics and communication, combined with the expertise of surgeons, enable customized treatments for patients.

Article 3 presents an overview of how new sensing, communication, and energy systems, engineered for the healthcare sector can be used to transform cardiovascular disease treatment procedures.

Article 4 examined Brain-Computer Interfaces and how they help in enhancing human vision, motor recovery for disabled limbs, and more.

Article 5 featured an informative webchat between Mike Depp, and Glen Capek from Molex, as they discussed trends in flexible electronics driving new solutions for medical wearables applications.

Article 6 discussed how immersive digital technologies like Augmented Reality (AR) and Virtual Reality (VR) make medical learning more engaging through lifelike experiences.

Final article was a roundup of the entire series that tried to give readers a snapshot of the potential of medical technologies in the present times.

About the sponsor: Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1,100 manufacturer brands. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.

References

[1] Noncommunicable Diseases Fact Sheet, World Health Organization, 13 April 2021, [Online], Available from: https://www.who.int/news-room/fact-sheets/detail/noncommunicable-diseases

[2] Designing Medical Wearables for Real-Life, Molex Electronics Solutions - YouTube, 21 May 2021, [Online], Available from: https://www.youtube.com/watch?v=3kxdlWuoda8&ab_channel=MolexElectronicSolutions