High Reliability Connectors in Space

Delivering the performance demanded by today’s space missions requires the ultimate in high-reliability connectors.

In the world of high reliability connectors, those destined for spaceflight face the toughest conditions. Missions can last years and travel huge distances with no chance for repairs. Connectors need to provide secure communications, even in the harsh environments found outside the atmosphere.

The exploration of space is very much in the news. One of the largest programs in recent space history is the Artemis program. This program will see humanity return to the Moon, and its launch vehicle is the Space Launch System. Completing its first successful mission in December 2022, the SLS forms the largest component of the program. However, the latest steps in our return to the Moon are not the only exciting initiatives in space.

The James Webb Space Telescope (JWST) was launched late in 2021. It is still sending us detailed images of galaxies born in the earliest days of the universe. The information that JWST has gathered is providing new insights into how stars and galaxies are formed. Its advanced capabilities will pave the way for some truly remarkable discoveries in the future. In addition to scientific missions, the last few years have also seen the beginning of an entirely new industry. Some of the richest people on Earth have offered tempting visions of commercial space tourism.

These high-profile events, while they capture the imagination of the public, represent just a small part of the picture. The exploration and exploitation of space is an everyday activity. There were more than 220 space launches in 2023 alone [1], carrying science missions and satellites into orbit and beyond.

The Toughest Environment

Even though spaceflight has become more common, the conditions in which these systems must perform are unlike any other. Space represents possibly the single most demanding environment known to engineering. Any equipment used in spaceflight is exposed to a whole range of extremes, from high and low temperatures and harsh radiation to the rigours of launch [2] and the vacuum of space.

The lack of atmosphere is especially unforgiving. On Earth, our atmosphere serves as a protective blanket that provides pressure, thermal insulation, and safety from harmful radiation. In space, this protection is stripped away, exposing equipment to potential damage.

Without the atmosphere to protect it, an object in space receives the full force of the sun’s radiation. When equipment is bombarded by direct sunlight, its temperature can quickly become dangerously high. In contrast, the parts of a spacecraft that remain in shadow are very cold. These extremes of temperature need to be considered when selecting the materials to be used aboard space vehicles. There are other sources of radiation, including galactic cosmic rays which are highly ionizing. These can harm delicate instruments or sophisticated electronic circuits.

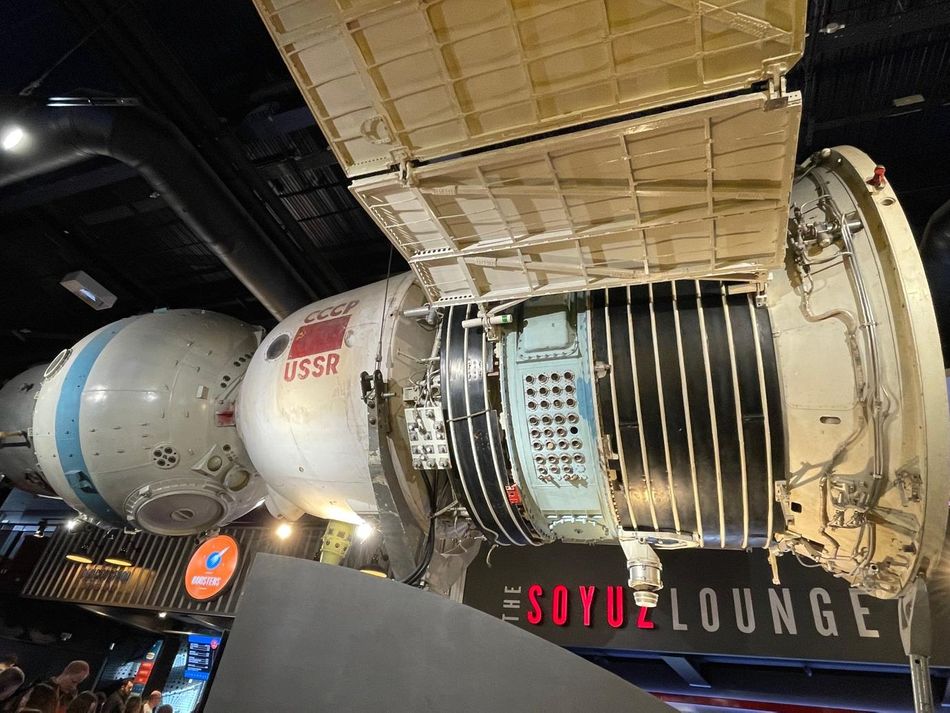

Image credit: Author

The Dangers of Outgassing

The lack of atmospheric pressure also causes materials to behave in unique ways. Outgassing [3] is a process in which a gas that has become trapped inside another material is released. This is a common problem when plastic is exposed to a vacuum during spaceflight, but it is not limited to plastics alone. Some metals are also prone to sublimation in vacuum conditions, including zinc and cadmium, both of which are commonly used in conventional equipment design.

In both cases, the gas that is released can cause damage. It may condense onto cold surfaces such as the optics and sensors of scientific equipment. This can degrade or even negate their effectiveness and put the entire mission at risk. Components also need to be mechanically robust as the launching satellites, probes and spacecraft into orbit exposes them to acceleration and vibration that can cause damage that might be undiscovered for months or years. Plastic components need to be manufactured of materials that exhibit high stability, even in vacuum conditions.

To provide solutions for these demanding conditions, connectors designed for spaceflight connectors are amongst the most advanced in the industry. Manufactured to stringent standards and tested to prove their performance even in the vacuum of space, they are the very definition of high reliability connectors.

Maximizing Endurance

If the spaceflight environment is not tough enough, there is one additional aspect that contributes to the challenges of designing for spaceflight, and that is endurance. Missions to space, whether they are intended for commercial purposes or scientific, can last for years. If a piece of equipment fails, it is impossible to gain access to fix the problem. In these circumstances, designers and engineers depend on the reliability of each of the components that make up the equipment, no matter how small.

Endurance also plays a key role in power planning. A long-range probe operates on a very strict power budget, and a component that introduces unwanted electrical resistance will risk jeopardizing the mission. The electrical contacts used in space-rated connectors will be made from the finest materials and manufactured to the closest tolerances. Contacts will be plated with gold to a thickness rarely seen in even the most demanding applications back on Earth. Gold plating ensures that the contact resistance is kept as low as possible to reduce power loss.

Contacts with a low electrical resistance are important for other reasons. Despite the sophistication of the instruments mounted to space probes, the measurements being taken can be tiny. When scientists are looking for minute fluctuations within magnetic fields or are trying to isolate a radiation signature from the noise of interplanetary space, unwanted electrical resistance can prevent a critical signal from being collected.

This is also the reason that manufacturers go to the trouble of reducing the magnetic signature of the components themselves to prevent interference with precision scientific experiments. Connectors designed for spaceflight applications use materials that provide the best possible performance. In just one example, the key feature of the D-subminiature connector is the trapezoidal shell that provides protection to the contacts and ensures correct mating. Traditional D-subs use shells made of steel, but versions destined for spaceflight use brass to minimize their magnetic signature.

The shell also provides protection against electromagnetic interference (EMI) [4]. In the vacuum of space, unprotected by a blanket of atmosphere, equipment is exposed to solar radiation which can interfere with scientific observations or even damage sensitive instruments. The shells of many spaceflight connectors are gold plated in the same way as the electrical contacts to provide the best possible protection against EMI.

Image credit: Glenair

Conclusion

Connectors play an often-overlooked role in spaceflight applications. Space vehicles are typically manufactured from sub-assemblies which are brought together before launch. Connectors provide the vital interface between each system, during both the extensive testing regime before launch and the demanding conditions found in space. Spaceflight connectors are designed to some of the highest standards in the interconnection industry and, as a result, represent some of the most capable products available today.

References

- https://www.spaceworks.aero/recap-of-all-global-launches-for-2023/

- https://blogs.nasa.gov/Rocketology/2016/02/25/think-youre-stressed-try-being-a-rocket/

- https://blog.samtec.com/post/what-is-outgassing-and-how-is-it-tested/

- https://www.techtarget.com/searchmobilecomputing/definition/electromagnetic-interference