Metamaterials - explanation and applications

The dimensioning of materials to suit our needs has soared in the last decade through the use of composites. There are other materials though, human made and industrially manufactured, that showed up later and are gaining a solid inertia of their own.

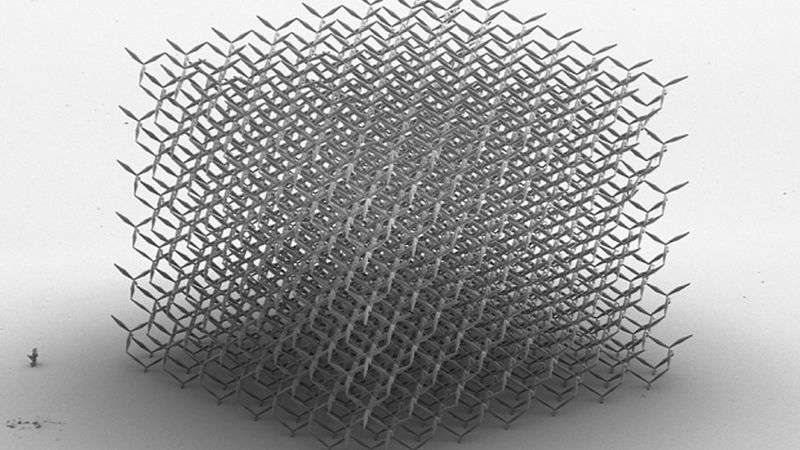

A pentamode metamaterial (size is approx 300µm) captured by SEM. Image courtesy of Tiemo.bueckmann, from Wikimedia Commons

This article was first published on

www.engineeringclicks.comThe dimensioning of materials to suit our needs has soared in the last decade through the use of composites. There are other materials though, human made and industrially manufactured, that showed up later and are gaining a solid inertia of their own. Amongst the most researched, Metamaterials (or MMS) stand out as ones which have almost developed their own science and multidisciplinary requirements to approach them. They are unique in many ways and we will now take a look at metamaterials in more detail.

Tailor-made materials

Metamaterials are tailored in a specific fashion so as to provide effective properties, otherwise impossible to find in natural materials. The main construction of them starts not with atoms or plies, but with unit cells created on the nanoscale and periodically arranged in a three dimensional space. The unit cells are made of small metallic resonators, commonly known as metametals. Their configurations, dimensions and gap are dimensioned to give the required features, mainly the electromagnetic ones that can interact with specific external electromagnetic waves and either absorb them, bend them or avert them.

In classic materials, the resonant magnetic permeability is an inherent property derived from dielectric response, itself dependent on the structure of the atoms. It is either taken in its original form or one adjusted to a small extent – but none of them can go above a few THz (terahertz). In the case of metamaterials, the construction allows desirable wavelengths of a wide range, otherwise not found in nature. This means that not only you can dimension the metamaterial to avoid any specific resonance phenomenon, but you can also manipulate electromagnetic waves. This is very useful in an array of different scenarios!

Metamaterials applications

Metamaterials have several practical areas: from providing protection from earthquakes to remote aerospace sensor detection, not to mention the famous invisibility cloaking (see the video at the bottom of this article). They are also candidates in the advancement of superlenses and smart solar power management systems and, currently, they are used in antennae transmission and semiconductors. One specific area attracting significant research at the moment is metamaterials which are able to provide a negative index of refraction for specific wavelengths.

Research

While many institutes, labs and networks have been teaming up to advance research, it is still predominately at the numerical phase, with prototyping proving pretty tricky. The manufacturing process is either too expensive or not realistic. Unfortunately, creating more than a unit cell and getting to a macroscopic scale will be long and flawed under the current technology.

Interestingly, some labs have managed to use the power of 3D printing to create a prototype by tweaking with the material (usually a plastic), while others have been able to use electron-beam lithography. However, given the process of building metamaterials, one logical and established pathway to manufacturing would be through nanotechnology and down scaling the devices where metamaterials are used. Currently, self-assembly and hybrid chemistry for metamaterials are under investigation by the European Commission.

Looking to the future

As usual, new and promising technology is exciting and the prospects of uncovering new uses is helping to push new boundaries. While the production of metamaterials is now well documented and the process well within current technological boundaries, one of the key issues not yet covered in great detail is the characterisation of the metamaterials and the other effective properties that will come into play. After all, metamaterials are called upon mostly for their electromagnetic characteristics, but given their crucial role, other features, mostly mechanic or thermal, should be taken into consideration. This will require a whole new set of technics when it comes to characterisation but thankfully there is a growing appetite amongst the engineering fraternity towards this area.