Online manufacturer supplies machined parts for prototypes resulting in significant time and cost savings

Festo relies on parts from Online Manufacturer FACTUREE to develop functional prototypes

This article was first published on

www.facturee.dePneumatic and electrical control and drive technology play an important role in factory and process automation. In this field, Festo, the world’s leading automation technology manufacturer, supplies the market with products, systems, and services aimed at a wide range of requirements. To ensure efficient development activities including the development of new series, Festo relies on machined parts supplied by online manufacturer FACTUREE (www.facturee.de) for its functional prototypes. FACTUREE offers a wide range of manufacturing services, short provisioning times, and on-time delivery, enabling Festo to offer a flexible, high-quality response to the latest customer and market requirements.

Festo SE & Co. KG is a group of companies specializing in control and automation technology. The independent family-owned multinational company supplies pneumatic and electrical automation technology to 300,000 customers in over 35 industries. Festo is a global leader in both automation technology and technical training.

Components for functional prototypes required on short notice

Festo regularly launches new products on the market. These innovations are subjected to preliminary analyses and extensive functional tests, using new components that are required on short notice. In order to prevent delays to its development processes and to protect its own resources, Festo sources machined components from FACTUREE – The Online Manufacturer.

Bodo Neef, Development Engineer at Festo, explains: “In the past, we often experienced bottlenecks when procuring prototype parts, which is why we decided to hand over production of the machined parts to FACTUREE.”

FACTUREE is a brand of cwmk GmbH, which has an extensive production network in the fields of CNC machining and surface technology. Advantages include a comprehensive system of partners, manufacturing technologies, and surface treatments, resulting in potential for savings, increased efficiency, and more reliable delivery, as unrestricted capacities and short supply times are guaranteed.

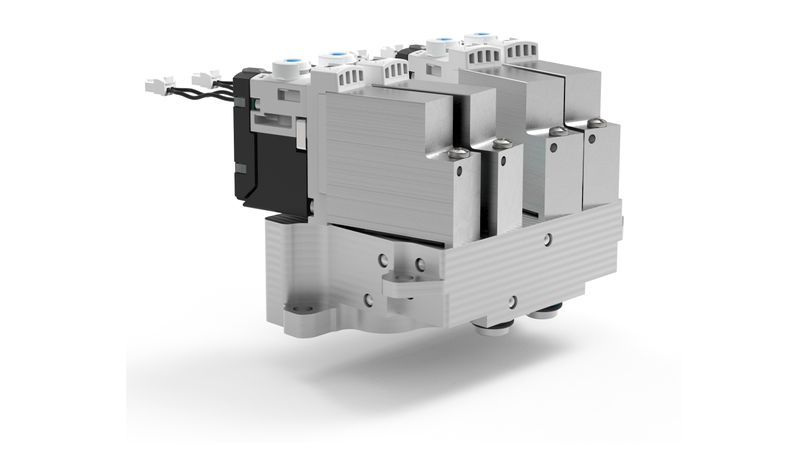

Among other assignments, Festo entrusted Berlin-based company FACTUREE with the manufacture of machined parts, including various designs of valve blocks, for the preliminary testing of a new positioner. The project also included the complete mechanical processing of special parts.

Axel Müller, a member of Festo’s positioner development team, says: “The components’ requirements involve very complex contours and superior surface quality. FACTUREE was the best fit of all evaluated providers. The wide range of production techniques as well as the guaranteed fast delivery time and the straightforward quotation process were decisive criteria. Some suppliers offer a similar portfolio, but could not deliver as quickly".

Online Manufacturing supports simple and fast procurement

The procurement process was very simple: 3D and 2D files created in-house by Festo were used by FACTUREE as production templates. The quote was prepared quickly. Festo was able to upload the prepared files and select the desired production method and material on the FACTUREE website. The components supplied by FACTUREE met all specifications and desired properties.

As a long-standing FACTUREE customer, Festo intends to continue its relationship with the component supplier and to adapt it to future requirements as needed.

“FACTUREE takes on the task of manufacturing complex components for special applications for us, freeing up valuable resources needed for other activities. Its reliable procurement process allows us to remain operational at all times, while thanks to its extensive network of manufacturing partners, FACTUREE is always able to offer us unrestricted capacity. The very reasonable quote was also a positive factor,” concludes Axel Müller.