ABS vs PETG: A Comprehensive Comparison for 3D Printing Materials

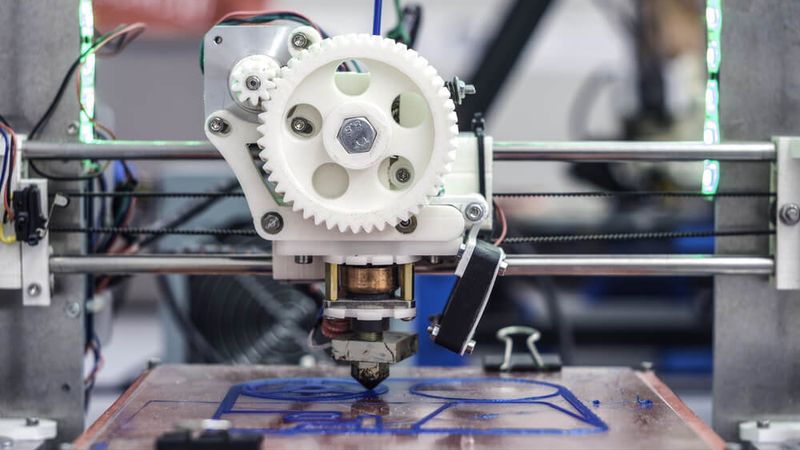

ABS and PETG are, along with PLA, some of the most affordable and widely used 3D printing filaments for extrusion-style printing. This article discusses the key differences between the two thermoplastic materials.

3D printing has revolutionized the manufacturing industry, allowing for rapid prototyping and production of complex designs. A crucial aspect of FDM/FFF 3D printing is selecting the appropriate thermoplastic material for a specific project. Two popular materials for 3D printing are ABS (Acrylonitrile Butadiene Styrene) and PETG (Polyethylene Terephthalate Glycol). Both materials have unique properties that make them suitable for different applications.

This article will provide an in-depth comparison of ABS and PETG, discussing their properties, printability, environmental impact, and cost. By understanding the differences between these materials, you can make an informed decision when choosing a material for your 3D printing project.

Overview of ABS

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic polymer commonly used in 3D printing due to its versatile properties. It is composed of three monomers: acrylonitrile, butadiene, and styrene, which contribute to its unique characteristics.

Properties of ABS

ABS is known for its strength, toughness, and impact resistance.[1] It has a tensile strength of 42 MPa and a flexural modulus of 2.4 GPa, making it a suitable material for applications requiring durability. Additionally, ABS has a relatively high glass transition temperature of approximately 105°C, which means it can withstand higher temperatures without deforming.

Common Applications of ABS in 3D Printing

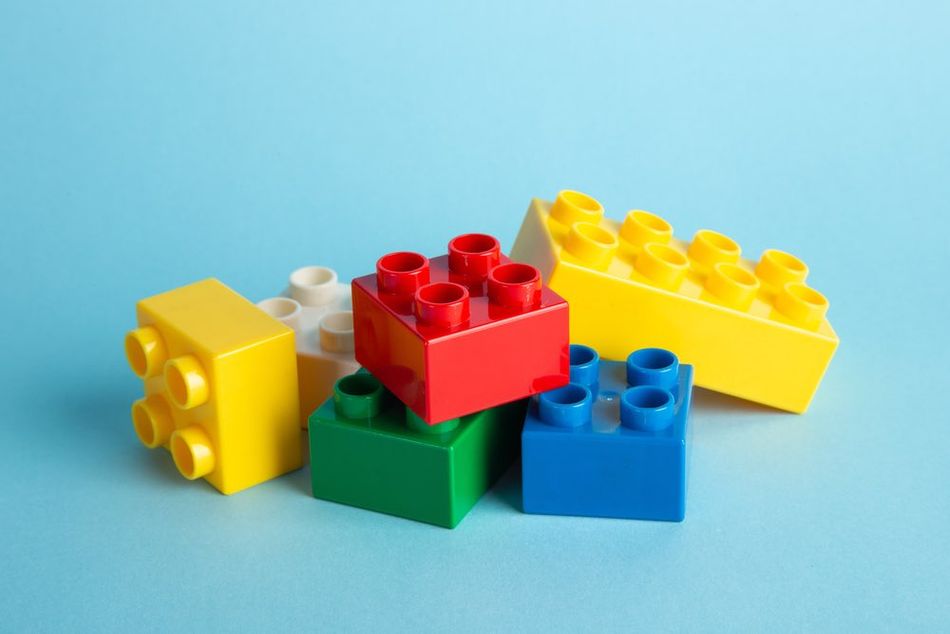

ABS is widely used in various industries, including automotive, consumer goods, and electronics. In 3D printing, ABS is often chosen for functional parts, enclosures, and prototypes that require strength and durability. Some examples of ABS applications in 3D printing include:

Automotive components, such as dashboard panels and interior trim

Electronic enclosures for devices like smartphones and laptops

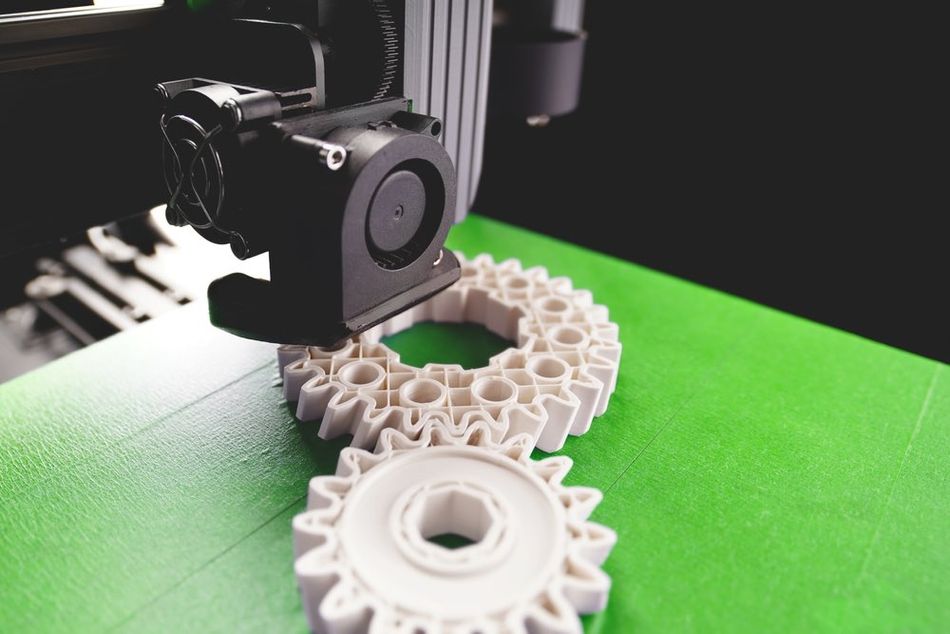

Mechanical parts, such as gears and brackets

Advantages and Disadvantages of Using ABS

ABS offers several advantages for 3D printing, including:

High strength and durability, making it suitable for functional parts

Good temperature resistance, allowing it to be used in applications exposed to heat

Ease of post-processing, as ABS can be sanded, painted, and glued easily

However, ABS also has some disadvantages:

It is prone to warping and shrinkage during the printing process, which can lead to dimensional inaccuracies

ABS emits unpleasant and potentially harmful fumes during printing, requiring proper ventilation

It is not biodegradable and can have a negative environmental impact if not properly recycled

Overview of PETG

PETG (Polyethylene Terephthalate Glycol) is another popular thermoplastic material used in 3D printing. It is a modified version of PET (Polyethylene Terephthalate) with the addition of glycol, which enhances its properties and makes it more suitable for 3D printing applications.

Properties of PETG

PETG is known for its excellent combination of strength, flexibility, and impact resistance. It has a tensile strength of 50 MPa and a flexural modulus of 2.0 GPa, making it stronger than ABS in some aspects. PETG also has a lower glass transition temperature of around 80°C, which means it is less prone to warping and shrinkage during the printing process.

One of the key advantages of PETG is its excellent layer adhesion, which results in strong and durable prints. Additionally, PETG is resistant to chemicals and UV light, making it suitable for outdoor use.

Common Applications of PETG in 3D Printing

PETG is used in a wide range of industries, including medical, food packaging, and automotive. In 3D printing, PETG is often chosen for its combination of strength, flexibility, and ease of printing. Some examples of PETG applications in 3D printing include:

Medical devices and equipment, such as surgical guides and prosthetics

Food-safe containers and packaging

Outdoor signage and fixtures that require UV resistance

Advantages and Disadvantages of Using PETG

PETG offers several advantages for 3D printing, including:

Excellent layer adhesion, resulting in strong and durable prints

Good chemical resistance and resistance to UV radiation, making it suitable for outdoor applications

Lower warping and shrinkage compared to ABS, leading to more accurate prints

Generally considered food-safe and can be used for food-related applications

However, PETG also has some disadvantages:

It is more prone to stringing and oozing during the printing process, which can affect the print quality[2]

PETG prints are more difficult to post-process, as the material is less responsive to sanding and painting

It has a lower glass transition temperature than ABS, making it less suitable for high-temperature applications

Material Properties Comparison

Strength and Durability

ABS has a tensile strength of 42 MPa and a flexural modulus of 2.4 GPa, making it a strong and rigid material. Its high glass transition temperature of approximately 105°C allows it to withstand higher temperatures without deforming. This makes ABS suitable for applications that require strength and rigidity, such as automotive components and mechanical parts.

PETG has a tensile strength of 50 MPa and a flexural modulus of 2.0 GPa, which indicates that it is stronger than ABS in some aspects. Additionally, PETG has excellent layer adhesion, resulting in prints that are strong and durable. However, PETG has a lower glass transition temperature of around 80°C, making it less suitable for high-temperature applications compared to ABS.

In summary, ABS is generally more rigid and temperature-resistant, while PETG offers better layer adhesion, durability, and overall strength.

Recommended reading: How Strong Are 3D Printed Parts? A Comprehensive Analysis

Flexibility and Impact Resistance

ABS is known for its toughness and impact resistance, which can be attributed to the presence of butadiene in its composition. This property makes ABS suitable for applications where parts are subjected to mechanical stress or impact, such as gears, brackets, and automotive components. However, ABS is relatively more rigid than PETG, which can limit its use in applications requiring flexibility.

PETG, on the other hand, offers a unique combination of strength and flexibility. Its impact resistance is superior to that of ABS, making it an excellent choice for parts that need to withstand impact or stress without breaking. PETG's flexibility also allows it to be used in applications where some degree of bending or deformation is required, such as snap-fit joints or flexible enclosures.

Temperature Resistance

ABS has a relatively high glass transition temperature of approximately 105°C. This means that ABS parts can maintain their shape and mechanical properties at higher temperatures compared to PETG. This property makes ABS suitable for applications where parts are exposed to elevated temperatures, such as automotive components, electronic enclosures, and mechanical parts that operate in high-temperature environments.

PETG has a slightly lower glass transition temperature of around 80°C. While this temperature is still suitable for many applications, it is lower than that of ABS, making PETG less resistant to high temperatures. This can limit PETG's use in applications where parts are subjected to high temperatures or in environments with significant temperature fluctuations.

Printability and Ease of Use

Print Settings

ABS and PETG require slightly different slicer settings in order to achieve the best results. Most slicers like Cura or Simplify3D will have preset profiles for both materials, typically with parameters set to roughly the following values.

ABS | PETG | |

Bed temperature | 95-110 °C | 75-90 °C |

Extruder temperature | 220-250 °C | 230-250 °C |

Part Cooling Fan | No | Yes |

Print Speed | 60 mm/s | 60 mm/s |

Print Temperature and Bed Adhesion

ABS prints well on a Kapton tape build surface

ABS prints well on a Kapton tape build surface

Print temperature and bed adhesion are critical factors that affect the success of a 3D print. ABS and PETG have different printing requirements, which can influence their ease of use and printability.

ABS typically requires a higher print temperature, ranging from 220°C to 250°C, depending on the specific filament brand and printer settings. A heated print bed is also necessary when printing with ABS, with bed temperatures usually set between 95°C and 110°C. This helps to minimize warping and improve bed adhesion.

To further enhance bed adhesion, various methods can be employed, such as using a build surface like Kapton tape, BuildTak, or PEI sheets. Additionally, applying adhesion aids like glue stick, hairspray, or ABS slurry (a mixture of ABS and acetone) can help secure the print to the bed and prevent warping.

PETG has a similar print temperature to ABS, typically ranging from 230°C to 250°C but the material is less prone to warping and shrinkage. A heated bed is also recommended for PETG, with bed temperatures set between 75°C and 90°C.

To improve bed adhesion for PETG prints, using a build surface like blue painter's tape, PEI sheets, or glass with a thin layer of glue stick can be effective. It is important to note that PETG can adhere strongly to certain surfaces, so care should be taken to avoid damaging the build plate during print removal.

Warping and Layer Adhesion

ABS is prone to warping due to its high glass transition temperature and the significant shrinkage that occurs as it cools. Warping can lead to poor bed adhesion, resulting in prints detaching from the build plate or exhibiting uneven surfaces. To minimize warping, it is essential to use a heated bed, apply adhesion aids, and maintain a stable printing environment with minimal temperature fluctuations.

Layer adhesion in ABS prints can be affected by various factors, such as print temperature, cooling, and extrusion settings. Ensuring proper layer adhesion is crucial for the strength and durability of the final print. To improve layer adhesion, users may need to fine-tune their printer settings, such as increasing the print temperature or reducing the cooling fan speed.

PETG is less prone to warping compared to ABS, thanks to its lower glass transition temperature and reduced shrinkage during cooling. This makes PETG generally easier to print and results in more dimensionally accurate parts. However, PETG can still experience some warping, so it is essential to use a heated bed and appropriate build surface to ensure good bed adhesion.

One of the key advantages of PETG is its excellent layer adhesion. PETG prints tend to have strong and durable layer bonds, resulting in parts that can withstand stress and impact without delamination.

Post-Processing Techniques

ABS is known for its ease of post-processing, as it can be sanded, painted, and glued easily. Sanding ABS prints can help remove layer lines and achieve a smooth surface finish. When painting ABS parts, it is essential to use a primer specifically designed for plastics to ensure proper adhesion of the paint. Additionally, ABS can be glued using various adhesives, such as cyanoacrylate (super glue) or plastic cement.

Another popular post-processing technique for ABS is acetone vapor smoothing. This process involves exposing the ABS print to acetone vapor, which dissolves the surface layer and results in a smooth, glossy finish. This technique can improve the appearance of the print and, according to some researchers, can even enhance its strength by sealing layer lines and reducing stress concentrations.[3]

PETG prints can be more challenging to post-process compared to ABS. While PETG can be sanded, it is generally more resistant to abrasion, making the sanding process more time-consuming and less effective in removing layer lines. Painting PETG prints can also be more difficult, as the material is less receptive to paint adhesion. Using a primer specifically designed for plastics and lightly sanding the surface can help improve paint adhesion.

Gluing PETG parts can be achieved using adhesives like cyanoacrylate (super glue) or two-part epoxy. However, PETG does not respond well to solvent-based adhesives, as it is more chemically resistant than ABS. Unlike ABS, PETG cannot be smoothed using acetone vapor, as it is not soluble in acetone. Alternative smoothing techniques for PETG are limited, and achieving a smooth, glossy finish may require more manual effort, such as sanding and polishing.

Recommended reading: Smoothing PLA 3D prints with sandpaper, solvents, and more

Environmental and Health Considerations

Biodegradability and Recycling

ABS is a petroleum-based plastic and is not biodegradable. This means that ABS waste can persist in the environment for an extended period, contributing to plastic pollution. However, ABS can be recycled, and many recycling facilities accept ABS waste. It is essential to properly dispose of ABS waste by recycling it whenever possible to minimize its environmental impact.

One potential solution to reduce the environmental impact of ABS is to use recycled ABS filaments, which are made from post-consumer or post-industrial waste. These filaments can offer similar print quality and mechanical properties as virgin ABS while reducing the overall environmental footprint.

PETG is also a petroleum-based plastic and is not biodegradable. However, PETG has a higher recycling rate compared to ABS, as it is widely accepted by recycling facilities due to its use in food packaging and other consumer products. PETG can be recycled into new products, reducing its environmental impact.

Similar to ABS, recycled PETG filaments are available, which are made from post-consumer or post-industrial waste. These filaments can provide an eco-friendlier alternative to virgin PETG while maintaining comparable print quality and mechanical properties.

Recommended reading: PLA Recycling: Can PLA 3D Printer Filament be Recycled?

Fumes and Ventilation

Fumes emitted during the 3D printing process can have health implications, making proper ventilation and safety precautions essential when using ABS and PETG. Both materials produce different types and levels of fumes, which can affect their suitability for various environments and users.

When heated, ABS releases volatile organic compounds (VOCs) and styrene, a potentially harmful chemical. Prolonged exposure to styrene fumes can cause irritation to the eyes, nose, and throat, as well as headaches and dizziness. In extreme cases, chronic exposure to styrene has been linked to more severe health issues.

To minimize the risk associated with ABS fumes, it is crucial to use proper ventilation when printing with ABS. This can include using an enclosed printer with a built-in filtration system or ensuring adequate airflow in the printing area by using an exhaust fan or opening windows. Additionally, wearing a respirator with an activated carbon filter can help protect users from inhaling harmful fumes.

PETG is generally considered to produce fewer harmful fumes compared to ABS. While PETG does emit some VOCs during the printing process, it does not release styrene. This makes PETG a safer option in terms of fume emissions, especially for users who are sensitive to styrene or have limited ventilation options.

However, it is still essential to maintain proper ventilation when printing with PETG to minimize the risk associated with VOC exposure. Using an enclosed printer with a filtration system or ensuring adequate airflow in the printing area can help maintain a safe printing environment.

Cost and Availability

ABS is a widely available 3D printing material, and it can be found in various colors and brands. The cost of ABS filaments can vary depending on the manufacturer, quality, and quantity. On average, ABS filaments are priced between $15 and $30 per kilogram. It is important to note that cheaper filaments may have inconsistent quality, which can affect the print results.

PETG is also widely available and comes in a variety of colors and brands. The cost of PETG filaments is generally slightly higher than ABS, with prices ranging from $20 to $40 per kilogram. The higher cost can be attributed to PETG's unique properties, such as its excellent layer adhesion and reduced warping.

Sourcing High-Quality Filaments at a Reasonable Price

To find high-quality filaments at a reasonable price, consider the following tips:

Research and compare different filament brands and read reviews from other users to determine the best options for your specific needs.

Purchase filaments in bulk or during sales to take advantage of discounts and lower the overall cost.

Experiment with different filament brands and types to find the best balance between cost and performance for your specific projects.

In conclusion, ABS is generally more affordable than PETG, but PETG offers unique properties that may justify the slightly higher cost for certain applications. The choice between ABS and PETG will depend on the specific requirements of the project, as well as the user's budget and preferences.

Conclusion

Choosing the right material for a 3D printing project is crucial for achieving the desired results. ABS and PETG are both popular materials with unique properties and advantages. ABS is known for its strength, rigidity, and temperature resistance, making it suitable for functional parts and high-temperature applications. PETG offers a combination of strength, flexibility, and excellent layer adhesion, making it ideal for parts that require impact resistance and durability. The choice between ABS and PETG will depend on the specific requirements of the project, such as strength, flexibility, temperature resistance, and environmental considerations.

Frequently Asked Questions (FAQs)

Can I mix ABS and PETG in a single print?

Mixing ABS and PETG in a single print is generally not recommended, as the materials have different printing temperatures and properties, which can lead to poor layer adhesion and compatibility issues. However, some advanced printers with dual extruders may be able to print with both materials simultaneously, provided that the user carefully adjusts the settings to ensure proper layer adhesion.

How do I store ABS and PETG filaments?

Both ABS and PETG filaments should be stored in a cool, dry place away from direct sunlight as they are both fairly hygroscopic. It is recommended to use airtight containers with desiccant packs to prevent moisture absorption, as moisture can negatively affect the print quality and performance of the filaments.

Are there any alternatives to ABS and PETG for 3D printing?

There are many alternative materials available for 3D printing, each with its unique properties and applications. Some popular alternatives include PLA (Polylactic Acid), which is a biodegradable and eco-friendly material; Nylon, which offers excellent strength and flexibility; and TPU (Thermoplastic Polyurethane), which is a flexible and highly elastic material. The choice of material will depend on the specific requirements of the project and the capabilities of the 3D printer.

References

[1] Selvamani SK, Samykano M, Subramaniam SR, Ngui WK, Kadirgama K, Kanagaraj G, Idris MS. 3D printing: Overview of ABS evolvement. InAIP Conference Proceedings 2019 Jan 11 (Vol. 2059, No. 1). AIP Publishing.

[2] Holcomb G, Caldona EB, Cheng X, Advincula RC. On the optimized 3D printing and post-processing of PETG materials. MRS communications. 2022 Jun;12(3):381-7.

[3] Gao H, Kaweesa DV, Moore J, Meisel NA. Investigating the impact of acetone vapor smoothing on the strength and elongation of printed ABS parts. Jom. 2017 Mar;69:580-5.

Table of Contents

Overview of ABSProperties of ABSCommon Applications of ABS in 3D PrintingAdvantages and Disadvantages of Using ABSOverview of PETGProperties of PETGCommon Applications of PETG in 3D PrintingAdvantages and Disadvantages of Using PETGMaterial Properties ComparisonStrength and DurabilityFlexibility and Impact ResistanceTemperature ResistancePrintability and Ease of UsePrint SettingsPrint Temperature and Bed AdhesionABS prints well on a Kapton tape build surfaceWarping and Layer AdhesionPost-Processing TechniquesEnvironmental and Health ConsiderationsBiodegradability and RecyclingFumes and VentilationCost and AvailabilitySourcing High-Quality Filaments at a Reasonable PriceConclusionFrequently Asked Questions (FAQs)Can I mix ABS and PETG in a single print?How do I store ABS and PETG filaments?Are there any alternatives to ABS and PETG for 3D printing?References