Prototyping, Custom Fabrication and Production

InDro Robotics expands with InDro Forge

InDro Robotics is excited to introduce InDro Forge, a cutting-edge prototyping and custom fabrication facility, situated in Ottawa. Formerly operated by Invest Ottawa as the Bayview Yards Prototyping Lab, InDro Forge is now under the operation of InDro Robotics. The facility is a ‘one stop shop’ for entrepreneurs and small to medium enterprises (SMEs) seeking the custom design and fabrication of prototypes.

What sets InDro Forge apart is its impressive array of state-of-the-art tools and machinery, all conveniently housed under one roof. From metal 3D printing to CNC machining, silicone and urethane casting, and more, InDro Forge offers a comprehensive suite of capabilities. The facility features a variety of tools for additive and subtractive manufacturing along with a team with the requisite expertise.

Several of the machines that distinguish InDro Forge are:

Maximum Part Size: 235 mm x 68 mm x 66 mm

Materials: Stainless Steel, Copper, Inconel, Tool Steels

Unique Advantages:

- When part geometries require large of amounts of waste in removing material through traditional processes, or are not possible through common subtractive machining, the Metal X shines. By 3D printing only the material needed and some support, the amount of material waste is limited and impossible geometries become available.

- Sometimes parts need to be metal due to their environments instead of the metals mechanical properties. When this is the case, the Metal X allows for low density parts similar to common FDM printing.

- To generate high quality finished parts there are a number of post or in-process finishing opportunities, these might include engraving part information prior to sintering or using traditional machine tools to improve the geometric accuracy of critical features after printing.

Maximum Material Size: 120” x 60” x 4”

Materials: Ferrous and Non-Ferrous Metals, Ceramics, Woods, Plastics

Unique Advantages:

- Because of its rapid and accurate cutting capabilities, it allows for low-cost 2D blanks of more complex parts to be made and then moved to other machinery such as the CNC Mill, Hydraulic Break for CNC Laser for finishing.

- The A-jet tilt-head function allows the head to maintain square edges regardless of material thickness or adding simple or continuously changing bevels to the edges of parts. A common example of this is adding hole chamfers directly into the part while cutting to reduce post-processing.

- Capable of working with materials anywhere from 1/8” Glass or Alumina Ceramic all the way up to 4” Steel, there are few materials which this machine can’t cut reliably and precisely.

BigRep One Large Format 3D Printer

Maximum Print Size: 105 cm^3

Materials: PLA, PETG, Hi-Temp, TPU

- When the part you need is bigger than your average 3D printer is capable of, but it doesn’t make sense to deal with the high start-up cost of injection moulding, vacuum forming or casting, the BigRep One is ready to deliver.

- It’s large format allows for the printing of large enclosure or similar complex structural components which are needed to validate fit, form or function of a design.

While the lab has traditionally excelled in the realm of rapid prototyping, it now extends its expertise to a broader scope. Inventors, startups and SMEs, can walk through the door with an idea, be it for proof of concept, Minimum Viable Products (MVPs), or functional models to showcase to potential investors.

Working with InDro Forge's skilled staff, clients receive a full-fledged industrial design that is then fabricated in any one (or combination) of a number of materials. The 3D printer alone can work with some 25 substances, including ABS and metal.

Check out 3D printers HERE

Rapid Prototyping and More

InDro Forge is an all-in-one- solution for companies that don’t have the equipment, time or expertise to carry out this highly specialised work.

With InDro Robotics at the helm, the synergy between InDro Forge and the Area X.O engineering team promises significant advances. InDro Forge will be able to draw on the expertise in aerial and ground robotics from our core R&D engineering hub, while InDro Robotics adds the design and fabrication capabilities of Forge to its portfolio of services. What’s more, InDro envisions expanding its offerings to include limited production runs and custom fabrication services.

“We see the value when people come to us with a napkin sketch and leave with a physical prototype they can show investors,” says InDro Forge’s Pablo Arzate, an industrial designer with special expertise in additive manufacturing.

Below: Advanced capabilities include a water jet machine, capable of slicing through several inches of steel.

The InDro Forge Advantage

InDro Forge is equipped with a wide array of additive and subtractive manufacturing capabilities, including:

- CNC machining

- Silicone and urethane casting

- Multi-element 3D printing (including metal)

- Electronics and Printed Circuit Board fabrication and analysis

View the full equipment list HERE.

The facility's machinery and capabilities are complemented by a team of highly skilled experts in industrial design and engineering, many of whom have years of experience in various fabrication processes.

For those seeking custom and complex fabrication, the InDro Forge advantage is clear. The facility caters to diverse needs, from one-off prototypes to comprehensive product development. It transforms rough ideas into refined, functional prototypes, bridging the gap between concept and product. InDro Forge's expertise is invaluable for those seeking to realize their innovative visions.

“If you don’t have these machines at your disposal, it’s definitely great to find a place with the expertise to help you out,” says O’Leary. “If you don’t have these capabilities, then we are here to help create the thing that you’re looking to create. We’re set up to help anybody who comes in with anything from an engineering project to a napkin drawing.”

InDro Forge offers services ranging from one-off prototypes to full product development.

“Some of our other clients come to us where they have an early prototype that they’ve cobbled together. It tells them that their idea is possible but it’s not a product yet,” says Joel Koscielski. “So we’ll help them turn that into a more refined version of itself. We might do one of those, we might do five – even 25.”

Projects can be big – or small.

“Sometimes it’s just that extra bit of capacity – they themselves have never had to make a sheet metal box that looks good,” adds Koscielski.

When asked about their favorite machines, team members at InDro Forge had compelling insights:

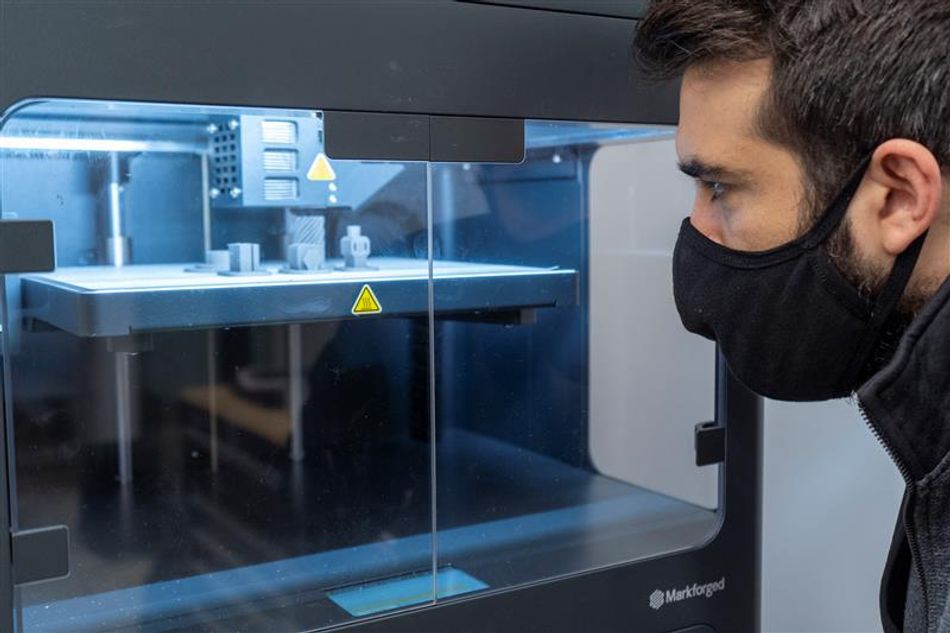

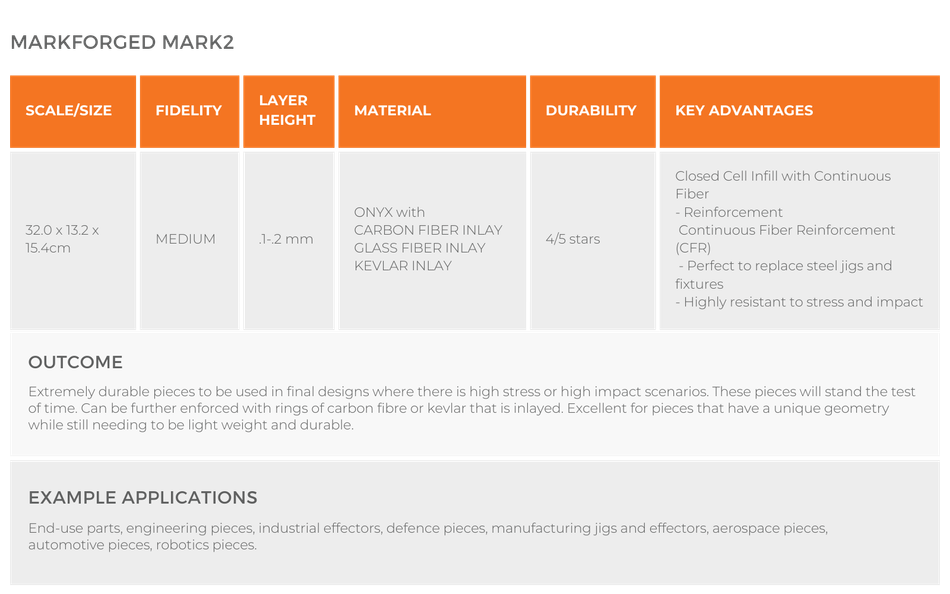

Pablo Arzate highlighted the Markforged II, praising its precision and versatility in 3D printing, especially its ability to fabricate parts with carbon fiber and nylon, opening up a world of possibilities for product development and rapid prototyping. The Markforged II specs:

Tom O’Leary's favorite machine is the water jet, capable of cutting through various materials with precision, akin to a "calligraphy pen with immense pressure," making it a versatile tool for shaping materials. The water jet specs:

Joel Koscielski also lauded the Markforged Mark II 3D Printer for its use of carbon fiber-reinforced nylon composite material, a true workhorse of innovation that produces high-quality, functional parts suitable for sales and demonstration purposes.

InDro Robotics considers the operation of InDro Forge a significant milestone. With a strong vision for the future, the company aims to serve a broad spectrum of clients, both large and small. In the words of CEO Philip Reece, "This is really just such a logical fit for InDro Robotics. Whether it's working with new clients or assisting our own, InDro Forge has all the right stuff – including the right people."

For more information on InDro Forge and its comprehensive capabilities, please visit www.indrorobotics.com/indroforge/.