Simplifying Material Selection for Engineers: A Technical Guide to Replique's Material Hub for Additive Manufacturing

In additive manufacturing, the selection of materials is crucial for achieving specific mechanical properties such as tensile strength and heat resistance. Replique's Material Hub offers a comprehensive database to aid engineers in making cost-effective and technically sound material choices.

The Role of Material Selection in Optimized Manufacturing

Additive Manufacturing (AM) offers the ability to create complex geometries with exceptional design freedom. Material selection is of central importance in AM to achieve desired mechanical properties like tensile strength, fatigue resistance, and heat deflection temperature, particularly in high-performance industries like aerospace, automotive, and medical devices, as it directly impacts the durability and overall performance of the final product. However, the process of balancing load-bearing capacities, thermal expansion, environmental stability, and cost efficiency poses a set of technical challenges that many engineers face. In this regard, the contract manufacturing platform Replique provides a solution with its Material Hub that simplifies material selection with a database rich in detailed performance data tailored for AM, enabling engineers to make informed choices efficiently.

The article provides a detailed approach for engineers to streamline material selection in AM, addressing the challenges of matching material properties to performance criteria and production constraints. It discusses how Replique's Material Hub integrates detailed material data and performance characteristics to provide engineers with a robust tool that optimizes decisions for mechanical strength, durability, environmental impact, and compliance with standards.

Engineering Challenges in Material Selection for Additive Manufacturing

Material Diversity and Performance Metrics

AM processes can utilize a wide range of materials, including polymers, metals, and composites, with unique mechanical, thermal, and chemical properties. Engineers must evaluate these materials in terms of specific performance metrics to ensure that these properties meet application requirements. For instance, polymers usually offer flexibility and chemical resistance, and metals provide superior tensile strength and thermal stability. Composites, on the other hand, can be tailored to achieve specific combinations of properties, such as high stiffness and low weight.

However, the microstructure and mechanical properties of parts manufactured by different AM techniques, such as Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM), can vary significantly from conventionally manufactured components, which necessitates a thorough analysis of material performance under these conditions.

Data Overload and Manual Selection Pitfalls

The sheer volume of material data available can be overwhelming for engineers. Filtering through technical datasheets, standards, and certifications to compare properties like Young's modulus, elongation at break, and thermal expansion coefficients is a time-consuming and error-prone process. This traditional, manual approach leaves engineers susceptible to pitfalls, such as inadvertently overlooking crucial data. For instance, high elongation at break may suggest resilience, but without considering factors like chemical resistance, the material may fail in specific environmental conditions.

Consequences of Material Mismatches

An improper material selection can lead to serious consequences, which can impact both product reliability and operational safety. For instance, structural integrity failures can lead to part deformations under stress. Similarly, inadequate thermal resistance can result in warping or degradation in high-temperature applications. These mismatches can lead to costly recalls or reengineering efforts, especially in industries where high precision is critical.

Leveraging Replique's Material Hub for Performance-Based Material Selection

Overview of the Material Hub Platform

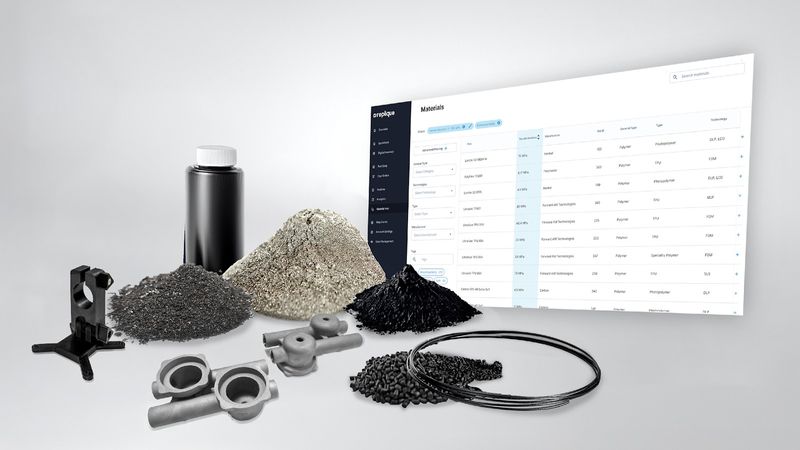

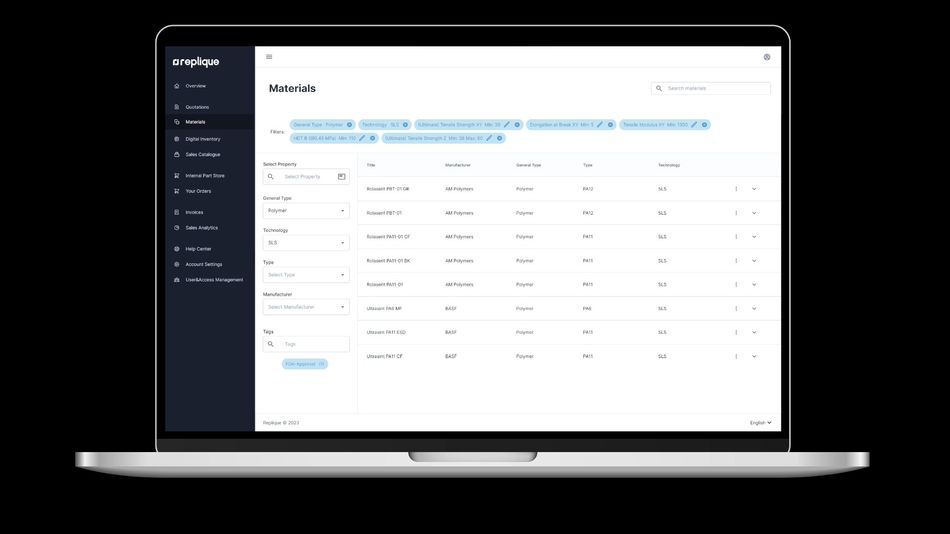

Engineers can address the challenges inherent in material selection for AM by turning to powerful tools like Replique's Material Hub. The contract manufacturer integrated these solutions to further democratize 3D printing, leveraging the extensive expertise gained from their vast network. Replique's Material Hub now provides access to an extensive database of over 500 materials from 30+ manufacturers in metals, polymers and composites, offering a comprehensive resource for engineers to search, filter, and compare materials specific to AM processes. The platform offers in-depth material descriptions, including stress-strain behavior, creep resistance data, and thermal expansion coefficients. This technical depth enables engineers to select materials suited to the specific performance demands of their designs. Once the right material is selected, the user can either order the part directly through Replique with the press of a button or contact the material provider for more information or to place a material order.

Advanced Filters for Engineers

The Material Hub provides advanced filtering capabilities to quickly identify suitable materials based on critical performance criteria. For instance, engineers can filter materials by mechanical properties such as Young's modulus, yield strength, and tensile strength or by thermal properties like thermal conductivity and coefficient of thermal expansion. Beyond these more common properties, the Material Hub also includes data on very specific properties like moisture uptake, comparative tracking index and industry-specific certifications such as railway flammability. These filters ensure that engineers can focus on materials that meet precise criteria without going through unnecessary data. For all property values, it is made transparent according to which test standards the data was obtained. After applying all the filters, engineers receive a list of materials tailored to their application needs. A simple comparison tool then helps them easily select the best fit.

Data-Driven Decision Making

Replique’s Material Hub eliminates much of the trial-and-error testing that engineers traditionally perform by providing a comprehensive set of data on fatigue life, impact resistance, and material aging under real-world conditions. This data helps engineers predict how materials will perform over time, particularly in demanding environments, reducing the guesswork traditionally associated with material selection. This data-centric approach accelerates development timelines, allowing engineers to achieve higher-quality outcomes with fewer resources.

Engineering Support from Replique

Replique not only offers the data platform it also provides direct support from technical consultants who assist engineers with material selection for complex applications. Their expert guidance is advantageous for engineers tackling unique and complex challenges, such as high-stress environments or extreme temperature resistance. Replique's technical consultants provide tailored advice that complements the Material Hub's resources and helps drive optimized material decisions.

Technical Benefits of Using Replique's Material Hub

Efficient Decision-Making

The Material Hub significantly reduces the time required to evaluate materials, which allows engineers to make decisions more quickly without compromising accuracy. For example, engineers working on high-stress applications like load-bearing components can specifically filter materials based on high tensile strength and fatigue resistance. Similarly, for heat dissipation components, materials with high thermal conductivity can be easily identified. This way, engineers can skip the traditional process of sourcing data from multiple sources, leading to substantial time savings.

Enhanced Product Integrity

Reliable, vetted material properties and performance data give engineers confidence that their designs will meet functional requirements without compromising safety or reliability. For instance, an engineer designing a custom prosthetic can use the Material Hub to select a material that meets both biocompatibility and fatigue resistance standards aligned with their unique design since, in medical device design, selecting biocompatible materials with appropriate mechanical properties is crucial to ensure long-term performance and patient safety. Similarly, in aerospace, where lightweight strength and temperature resilience are critical, engineers utilize the Material Hub to choose materials that optimize component performance and durability.

Increased R&D Efficiency

Research and Development cycles in AM usually involve iterative prototyping to validate material suitability, which can be time-consuming and costly. Replique's Material Hub can significantly accelerate the research and development process by reducing the time and cost associated with material qualification.

Moreover, by providing access to the latest materials and performance metrics, the Material Hub supports engineers in staying ahead of industry trends and exploring new materials that could enhance future designs.

Conclusion: Empowering Engineers with Comprehensive Material Insights

Replique's Material Hub provides engineers with a data-centric tool to tackle the complex task of material selection in additive manufacturing. The platform empowers engineers to make material choices by consolidating material performance data, integrating advanced filtering options, and offering expert support, which ultimately leads to improved product performance, reduced development time, and increased manufacturing efficiency.

Engineers looking to reduce material selection errors, optimize production efficiency, and innovate with confidence in their AM designs should check out Replique's Material Hub invaluable resource.

Reference

Choose the perfect material for your 3D printing application. Replique. Available at: https://replique.io/material-hub/ (Accessed on: November 13, 2024)