Subterranean drone tackles food security

An interview with the winner of the High-Temperature Carbon-fiber 3D Printing Challenge.

The High-Temperature Carbon-Fiber 3D Printing Challenge invited engineers and designers to submit ideas on how to leverage cutting-edge materials from Mitsubishi Chemical Advanced Materials. Participants in the challenge were asked to incorporate the strength and properties of the KyronMax® carbon-fiber 3D printing filament with the flexibility and sustainability of 3D printing in their design.

The challenge focused on three main criteria: technical and commercial feasibility, scalability and sustainability. In this series of articles, we are featuring the finalists and winners of the challenge sharing their vision and ideas for the future.

In this article, we talk to founder and CEO of CROVER, Conti Lorenzo. CROVER is a Scottish-based startup who have developed a novel robot that can crawl through stored grain. CROVER were the overall winner of the High-Temperature Carbon-Fiber 3D printing challenge.

CROVER

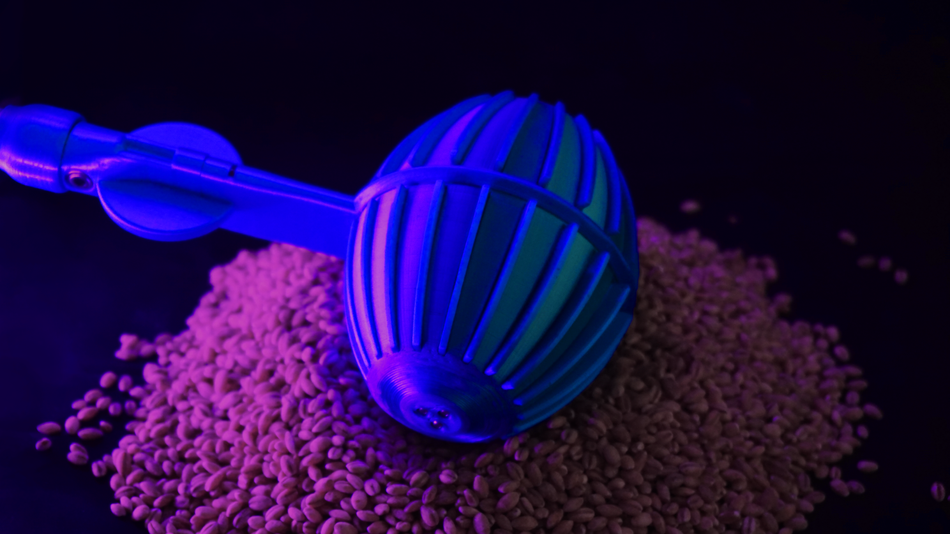

CROVER was founded to tackle issues around grain storage. "We have developed the world’s first subterranean drone or a CROVER robot as we call it, since there is no word in the dictionary to define that. We are tackling the problem of grain storage, as it is one of the biggest bottlenecks in its supply chain. The first use-case of the CROVER robot is to help grain storage operators maintain the quality of their stock,” explains Conti.

Storing grains for a long time after harvest leads to spoilage due to insects, pests, and mold formation. It is estimated that every year approximately 630 million metric tons of grain are lost due to spoilage. As a result, grain merchants, millers, and brewers have high-cost implications owing to lost revenue and the cost of rectification.

Grains should enter and leave silos with the same quality

The motion of the robot is based on the ‘Crover Effect’ for locomotion in granular media, which enables the drone to move fluidly through grains, sand, powders, and other granular media. “What we discovered is that, in any granular media, a coupling exists between rotational and translational motion,” Conti describes. “Essentially, this means that a rotating object navigates through the granular medium by creating a pressure difference on one side which pushes it forward.”

Human inspection of grain storage is a labor-intensive process and poses health and safety risks for the workers. "The CROVER robot aims at substituting human intervention on the surfaces of the grains. It can measure moisture, temperature, and stock levels by navigating through the grains whilst monitoring its storage conditions." This motion also facilitates mixing of the grains, which helps in maintaining the grain quality by improving aeration and avoiding problems like crusting on the surface. "We want to improve and automate grain monitoring and management activities, ensuring minimal human intervention," continued Lorenzo. The timely quality checks conducted by the robot would ensure that grains enter and leave the silos with the same quality.

Maximizing fresh grains at the end of supply chain

Initially, the CROVER team were searching for ways to integrate the ‘Crover effect’ of locomotion into a product. Lorenzo and his team brainstormed and analyzed different areas and markets where this technology could potentially be implemented. “We analyzed different possibilities keeping several factors like economics and social impact in mind. The grain storage industry took all the ideas out of the park. We identified problems associated with grain quality, as a lot of food is contaminated with mycotoxins (a disease-causing fungus). Mycotoxins are very harmful for humans and need to be controlled,” explained Conti.

The CROVER robot employs a simple method of mixing the grains which helps preserve their freshness and quality for a longer time. The act of mixing ensures the prevention of crust formation on the grains. Moisture tends to get trapped inside the crust, which accelerates grain spoilage. Therefore, it’s important to ensure that the grains are mixed from time to time. "Technically, grains have no expiration date as long as they are stored under the right conditions. The key is to store them in an environment with balanced temperature and moisture levels," continued Lorenzo.

Entering the High-temperature carbon fiber challenge

The Crover team were the overall winner of the high-temperature carbon fiber challenge. They are currently working with Growth Garage, the Business Incubator of the MCG Advanced Materials Division on developing and scaling their project.

"There are many competitions and challenges out there, but most of the time the support is quite generic. There isn’t much focus on the hardware side of products. The thing that really caught our eye in Growth Garage’s challenge was the support pertaining to manufacturing with 3D printing and material selection," continued Conti.

"The support comes at the perfect time for us as we are aiming for our first batch of commercial sales this summer. Materials are not our area of expertise and we are looking to continue improving the CROVER robot for the various harsh operating conditions. We are looking forward to the support in manufacturing and finalizing our choice of materials."

Follow Growth Garage's LinkedIn page for more interesting stories about 3D printing entrepreneurs in various fields.

About Mitsubishi Chemical Advanced Materials and Growth Garage

Mitsubishi Chemical Advanced Materials (MCAM) is a leading global manufacturer of high-performance thermoplastic materials in the form of semi-finished products and finished parts. Our specialty engineering composites can outperform metals and are already used in a wide range of applications, from aeronautics to bioprocessing.

Growth Garage is the business startup accelerator of MCAM. Our mission is to support and nurture new ideas using our advanced technologies, technical expertise and advanced composite materials. We are offering the opportunity for engineers and innovators to pitch us their ideas. The winners of our challenges will receive our full support, expertise and materials to help develop their projects from initial prototype to final product.

The Composite Engineering Challenge

We are inviting innovators, entrepreneurs, and early adopters at universities, (pre-) startups, and scaleups that need fiber-reinforced composites to realize their prototype, part, product, or application.

We welcome projects, programs, and companies in the field of new mobility (EV, e-motor, battery casing, etc.), autonomous (delivery) vehicles, people movers, robotics, aerospace, space, bicycles, UAV, AAV, bionics (wheelchairs, exoskeletons, prosthetics), alternative energy (production, storage, transport), self-sensing or self-healing, sport & leisure, alternative (low carbon footprint) fibers and more!

The winning entry will be rewarded with a partnership with Growth Garage, Business Incubator of the MCG Advanced Materials Division.

This partnership package is valued at $25,000 and will be tailored to the winning team’s needs according to their current business and product development stage.

READ MORE ABOUT THE CHALLENGE HERE.

Key Dates

|