The pivotal role of battery management systems on the performance of electric vehicles

As EV batteries become more powerful and complex, ever more sophisticated battery management systems are needed to ensure the safe, reliable, and cost-efficient operation of electric vehicles.

Image: Infineon

Introduction

Once a luxury used primarily by early adopters, electric vehicles (EVs) are becoming increasingly commonplace due to rising awareness about carbon emissions and their impact on climate change, supportive government policies, volatile oil prices, and growing cultural acceptance of green energy use. Global EV stock is projected to reach 243 million by 2030 - over 30 times higher than today’s level [1]. Most major car manufacturers are planning either a complete shift or a transition to EVs [2].

As demand for electric vehicles increases, so does demand for improved performance, including decreased cost and charge time, increased range and battery life, and improved safety. The cost of EV batteries continues to fall and EV battery technology is advancing rapidly in the form of increasing capacity and energy density [1, 2]. However, increases in energy density are accompanied by a growing challenge - safety. In particular, lithium ion batteries - the power source of choice for EVs thanks in part to their high energy density - are susceptible to overheating, and even explosion, and safety incidents have been widely reported [3, 4]. As EV batteries become more powerful and complex, ever more sophisticated battery management systems are needed to ensure the safe, reliable, and cost-efficient operation of electric vehicles.

What is a battery management system?

Battery management systems (BMS) are electronic control circuits that closely and accurately monitor and regulate the charging and discharging of rechargeable batteries, serving as the “brains” of an EV battery system. The BMS maintains batteries within their safe operating area and ensures optimal use of the residual energy in batteries, thereby maximizing their safety, reliability, durability, and performance.

Functions of battery management systems

Battery management systems are central to the safe and efficient operation of electric vehicles and perform a broad array of functions, including:

Battery monitoring

The BMS monitors the state of an EV battery system through a variety of direct and indirect measures. Current, voltage, and surface temperatures of battery cells are directly measured using sensors. These are in turn used to estimate the battery pack State of Charge (SOC), which indicates the charge level of the battery; the State of Health (SOH), which represents the remaining capacity of the battery pack and indicates when it should be replaced; the internal temperature of battery cells; and other parameters. Accurate voltage monitoring is of particular importance, since voltage deviations due to overcharging, over-discharging, or high power pulses can lead to significantly reduced battery life and safety issues.

Battery protection

The BMS is also equipped to prevent operations outside the safe operating area of and damage to the battery system, for example due to overcharging, over-discharging, or high temperatures. The action of the BMS can be physical (such as emergency shut down of the battery) or informational (by triggering an alarm or otherwise reporting trouble to the driver).

For example, the BMS controls the charger to protect the battery from overheating as well as ensure optimal charge of the battery, thereby prolonging its life and improving capacity utilization. The BMS is also responsible for thermal management of the battery. Battery temperature has a significant impact on battery life and performance, and the BMS controls the pump, fans, coolant (where relevant), and heater to maintain the temperature of the battery pack within its optimum operating range.

Battery optimization

The BMS also optimizes battery performance via a process called cell balancing. Within an EV battery pack, no two cells are identical, due to manufacturing differences as well as variation in their on-vehicle environment. Weaker cells charge and discharge faster than other cells. Because charging and discharging stop as soon as any cell hits programmed upper and lower capacity limits, the weaker cells cause energy within the other cells to go unused while discharging and limit the capacity of the battery pack while charging. This also results in an increase in the number of battery charge and discharge cycles, which shortens the lifetime of the battery.

Cell balancing helps resolve these issues and ensure optimum performance of the battery by equalizing the individual cells’ state of charge. Two types of cell balancing can be used – passive and active. In passive balancing a bleed resistor is used to dissipate energy from cells with excess charge until all cells have a similar state of charge. While this approach is lower cost, it is also less efficient since excess energy is lost as heat. Active cell balancing is a more complex technique that redistributes charge between cells during the charge and discharge cycles. While it is more efficient, since energy is transferred to where it is needed instead of being lost as heat, it also requires additional components at higher cost. Either method extends battery life and improves safety by preventing damage to battery cells due to overcharging or over-discharging.

High precision cell voltage and temperature measurements and robust communication links between cells and to battery controllers can further contribute to optimizing battery performance. By collecting better measurements and communicating them faster, the BMS can be more responsive to battery conditions and enable more efficient use of the battery.

Communication

The BMS also facilitates communication of information to the driver, for example by triggering an alarm or reporting the state of charge, as well as to other on-board equipment, for example to request changes in vehicle operation in response to monitored battery pack conditions.

Design of battery management systems

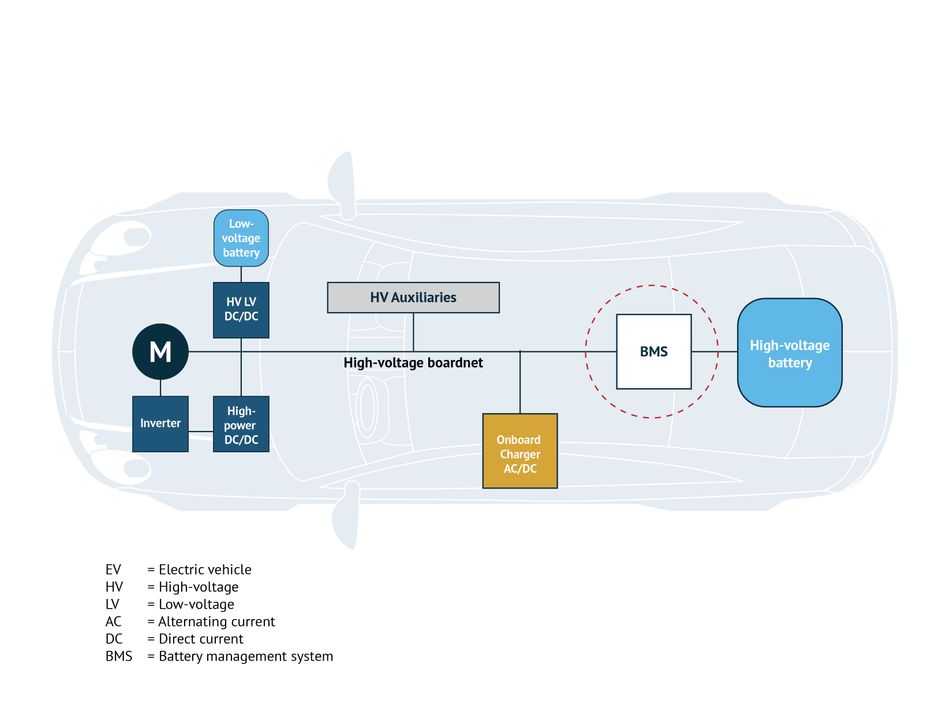

Electric vehicles are powered by hundreds or even thousands of individual battery cells. These cells are connected in modules in series and parallel and placed inside a steel casing to form the battery pack. Battery packs are typically very large, occupying the entire floor area of an EV, and are connected to the BMS and thermal management system. The BMS transmits information from the battery pack to the controller, which converts the DC voltage produced by the battery pack and drives the motor, and the rotational energy from the motor is transferred to the wheels by the transmission system (Figure 1).

The BMS itself is a combination of hardware and software (Figure 2). Hardware includes sensing microchips, transceivers, power management microchips, and microcontrollers. The sensors measure battery voltage, current, and surface temperature to monitor the condition of individual cells. Transceivers relay information between components. Power management microchips allow the connection and isolation of the battery pack between the charger and load. Microcontrollers receive information from sensors and plug it into algorithms which model internal battery states, such as internal temperature, SOC, and SOH. Once these internal states have been defined, the microcontroller can make decisions, such as optimizing the charging and discharging of the battery or triggering alarm or safety modules.

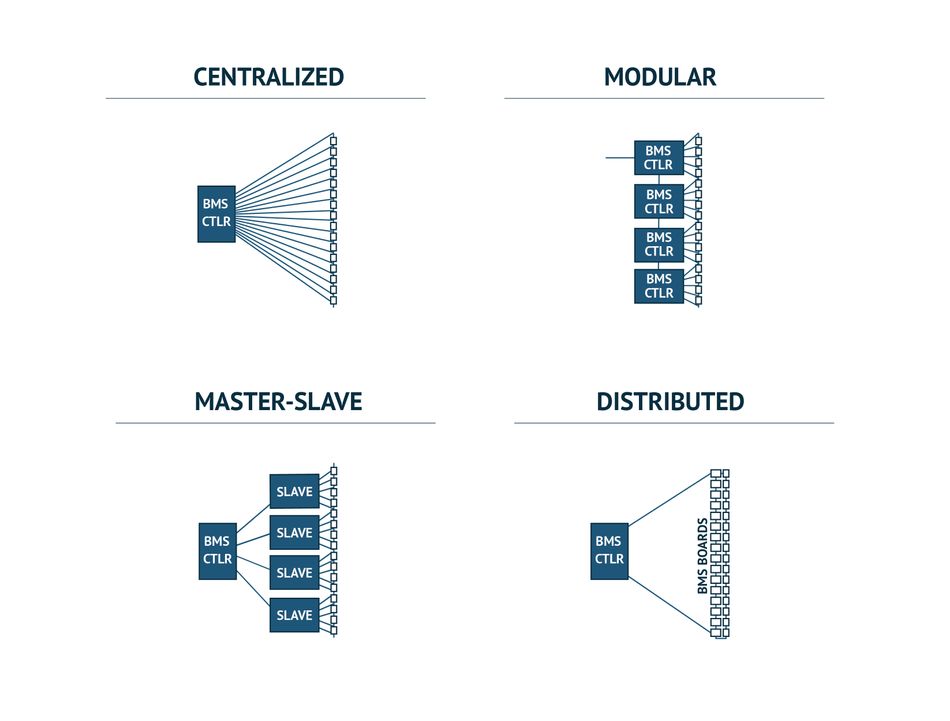

Battery management systems can be implemented using a variety of architectures. The choice of architecture has a significant impact on the cost, development time, flexibility, and reliability of a BMS. Architectures can be broadly classified as centralized and decentralized (Figure 3). In centralized architectures, a single controller monitors, balances, and controls all battery cells and is connected to them through a large number of wires. This approach is relatively inexpensive but also challenging to expand. In decentralized architectures, which include distributed, master-slave, and modular architectures, the BMS functionality is not concentrated on a single circuit board. These approaches entail fewer wires and are more flexible, but also more expensive.

Generally speaking, decentralized architectures are advantageous because they offer superior measurement precision, because shorter wires are less susceptible to noise; more reliable connections, because shorter wires are less prone to disconnection due to mechanical shocks and vibrations; scalability; and more robust communication between components.

Achieving reliable, high performance communication is a key challenge faced by BMS designers. Besides opting for decentralized architectures, designers can improve communication between components (and therefore achieve more accurate, real-time measurements and control) by using microchips which consolidate a variety of functions and controllers with built-in diagnostic functions. Minimizing the number of components, as well as the size of the components which are used, offer the added benefit of giving designers more flexibility and allowing for optimal placement of components within the vehicle.

Another challenge BMS can help designers tackle is security. Because EVs (including smart vehicles and autonomous vehicles) connect to the internet, these vehicles run the risk of cyberattacks. BMS security controllers can prevent unauthorized modification of the battery system, protecting the safety of the system as well as privacy and intellectual property.

What’s next for battery management systems?

Demand for improved performance and societal changes are driving new developments in battery management systems. One trend which promises major improvements to the performance and cost of EVs is the advent of wireless BMS. In a typical BMS, components are connected by a large amount of wiring - up to several kilometers long - which adds weight to the EV and makes it less efficient. This wiring is also costly and prone to mechanical failure. Furthermore, the wiring can make it so complex and time consuming to replace an individual battery cell that it makes more sense to simply replace the entire pack. By eliminating the need for wiring and associated components, a wireless BMS helps decrease the weight and size of the BMS, thereby improving vehicle efficiency, extending driving range, and helping make vehicles easier and cheaper to produce and maintain. At the same time, wireless BMS could offer even more accurate and useful information about the condition of the battery cells.

Another development is the increasing expectation that BMS components meet the most stringent safety standards. The safety of automotive components is assessed according to the ISO26262 standard, defined by the International Organization for Standardization (5). During the development of hardware and software components, all potential hazardous scenarios are evaluated for a particular component and classified based on the levels of severity, probability of occurrence, and driver controllability. The component is then assigned an Automotive Safety Integrity Level (ASIL), which indicates the level of safety required by the component to function normally without posing any threats to the vehicle. ISO 26262 defines four ASIL levels - A, B, C, and D - where ASIL D refers to the highest level of safety required. Vehicle manufacturers increasingly demand that BMS components are ASIL D compliant. At the same time vehicle designs are becoming increasingly complex, meaning that BMS suppliers need to be more rigorous than ever to meet safety requirements and ensure that EVs can operate safely.

Finally, a rapidly evolving and urgently needed development for EVs is fast charging, especially for buses and shared mobility vehicles which need to operate continuously (6). With the established AC charging, it can take several hours to fully charge an EV, whereas fast charging enables this within about 20 minutes. Batteries undergoing fast charging require more sophisticated battery management and much more accurate estimations of conditions inside battery cells to prevent overcharging and overheating.

Conclusion

As electric vehicles become increasingly ubiquitous, so will demand for EVs to offer performance and cost which is comparable to that of traditional vehicles. By improving the safety and reliability of EVs, increasing the efficiency and range of EVs, and prolonging EV battery lifetimes, battery management systems will play a pivotal role in achieving comparable, affordable performance, thereby enabling society to reap the benefits of EVs on a large scale.

About the sponsor: Infineon Technologies

Infineon Technologies provides semiconductor products for use in a wide range of applications. Infineon Technologies is dedicated to developing integrated circuits and design resources for battery management systems that contribute to more efficient, longer-lasting, and reliable battery-powered applications. To learn more click here.

References

Global EV Outlook 2020 – Analysis - IEA [Internet]. IEA. 2020. Available from: https://www.iea.org/reports/global-ev-outlook-2020

Figueres, C. Nature. [Online]. Available from: https://www.nature.com/articles/d41586-018-07585-6

Ouyang D, Chen M, Huang Q, Weng J, Wang Z, Wang J. A Review on the Thermal Hazards of the Lithium-Ion Battery and the Corresponding Countermeasures. Applied Sciences. 2019;9(12):2483.

A Review of Battery Fires in Electric Vehicles [Internet]. Springer. 2020. Available from: http://A Review of Battery Fires in Electric Vehicles

ISO 26262-1:2018 [Internet]. ISO. 2020. Available from: https://www.iso.org/standard/68383.html

Xinfan L. Modeling and Estimation for Advanced Battery Management [Internet]. Annual Reviews. 2020. Available from: https://www.annualreviews.org/doi/full/10.1146/annurev-control-053018-023643