What is inkjet nozzle plate? Electroformed inkjet nozzle plate in 5 steps

Inkjet nozzle plates are one of the most important components of inkjet print heads, as the quality of the nozzle plates directly determines the resulting printing performance of the whole system. This article introduces what an inkjet nozzle plate is, how this important component works, and how it is manufactured.

inkjet printing

The Inkjet nozzle plate is the single most critical component of an inkjet print head. These small and precise components are designed for high-performance jetting to distribute ink droplets with accuracy, speed, and longevity. Located at the heart of an inkjet printhead, an inkjet nozzle plate controls the formation and distribution of the microscopic droplets of ink that form the printed images on different surfaces. It contains tiny capillaries, or narrow channels, that are etched/lasered/Electroformed on the plate surface. When pressurized, ink flows through these channels and out of the nozzle, forming a precisely dosed droplet.

The quality and performance of an inkjet nozzle plate depend on several factors. These include the shape, size, and number of the nozzles, their diameter, and the overall surface area of the plate. Additionally, the type of material used to produce the inkjet nozzle plate is also important. The most common materials used in inkjet nozzle plates include stainless steel, nickel, brass, copper, aluminum, and plastic. Each of these materials has its own advantages and disadvantages in terms of production and printing quality.

Several methods are available for producing inkjet nozzle plates, such as Electroforming, Chemical Etching, and laser cutting. Electroforming is one of the most popular technologies for producing inkjet nozzle plates. It utilizes electrical current to grow thin metal layers on the substrate material. This technique produces high-precision nozzle structures with accurate control over the etched shapes and sizes. Additionally, electroforming allows for combining different metals, allowing for the cost-effective production of complex designs.

As the industry-leading specialist in Electroforming and with over 25 years of experience with inkjet nozzle plates, Veco offers customized inkjet nozzle plates manufactured by Advanced Lithographic Electroforming. With our Advanced Lithographic Electroforming technology, advanced features such as multi-layer nozzles can be achieved with high accuracy and reproducibility.

See below how a customized inkjet nozzle plate is produced with Electroforming in 5 steps:

1. A well-controlled process as a solid base

After determining the requirements of the customer in a technical discussion, the production process can start.

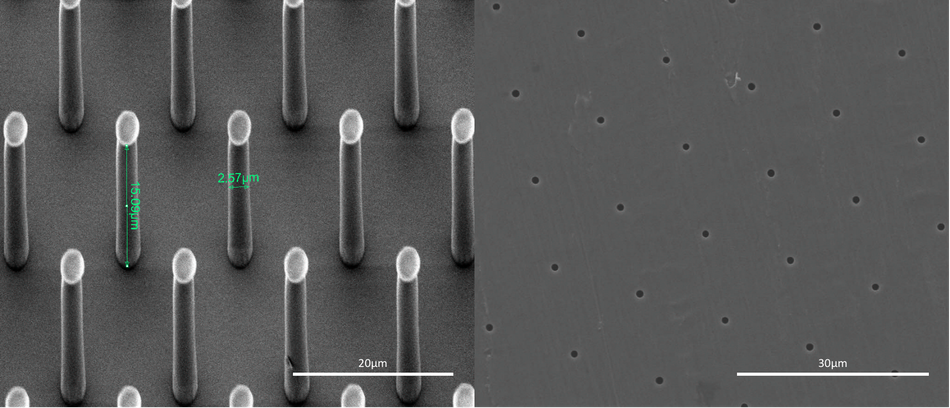

First, a custom metal plate (mandrel) with a patterned photoresist layer on top is made. Onto this mandrel, the metal is grown during the electroforming process. This step is very important because the final dimensions of an electroformed part are directly influenced by the accuracy of the mandrel.

Before starting the process, the mandrel is strictly measured, determining the shape and size of the holes in the inkjet nozzle plate. The holes in the produced nozzle plate will have the exact dimension the customer requires, with no flats or blockings. The variety of diameters of each nozzle can be as good as within ± 1µm between parts.

Recent lithographic developments allow for even tighter aperture size control down to ±500nm, a nozzle pitch of 30µm, and more freedom in defining the aperture shape. A well-controlled photolithographic process as a solid base tackles any unwelcome surprises.

Right: Resulting nickel sheet grown between the pillars with tightly defined holes.

2. Using the correct method to control accuracy

Once the mandrel is finished, it is time for the electroforming process.

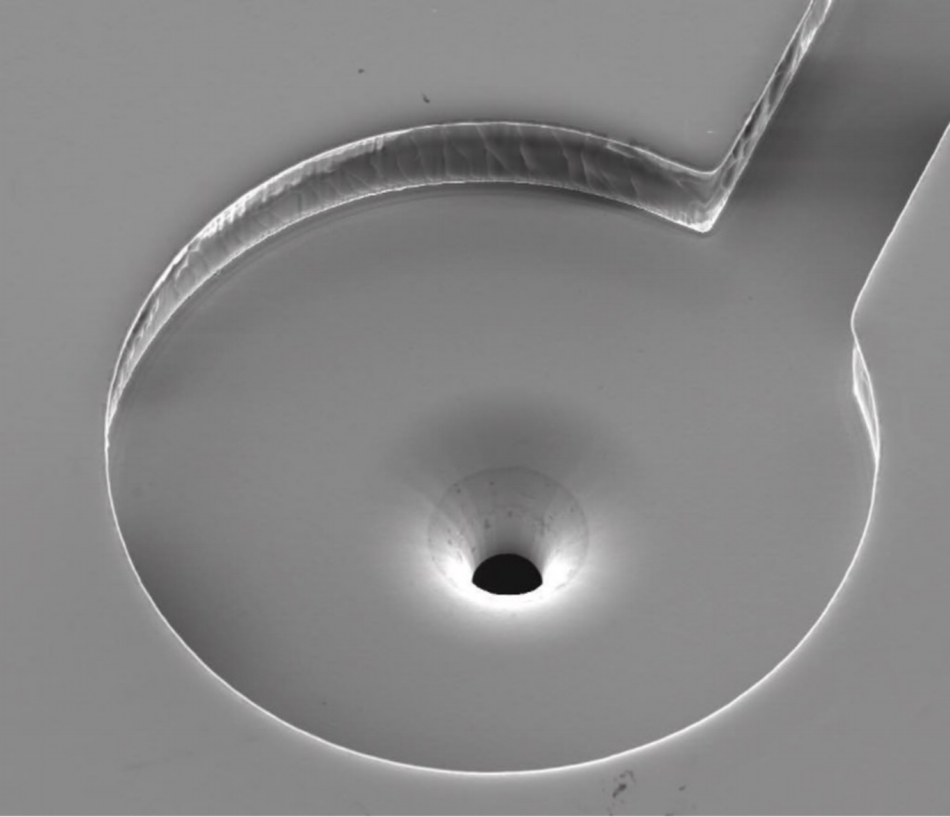

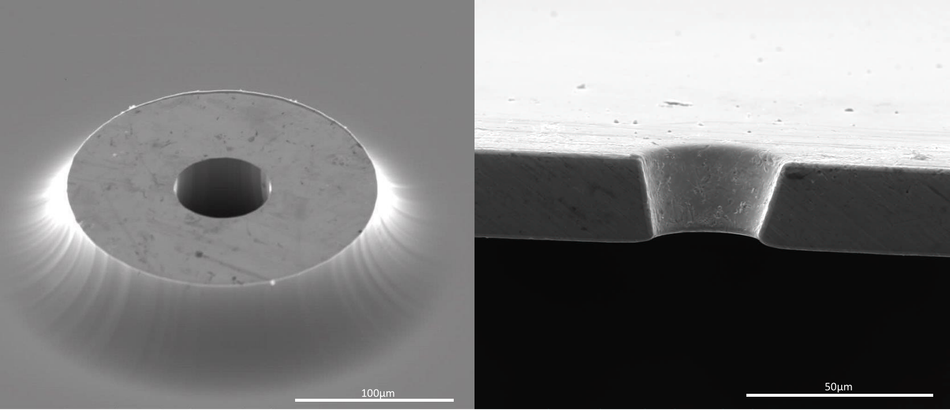

Usually, the overgrowth method is applied to shape the apertures. This means growing the metal over the thin layer resist, creating bell mouth-shaped apertures with tightly controlled dimensions.

Examples of different possible nozzle forms.

3. Protecting the plated product

After the electroforming process, gold or palladium-nickel coating can be applied to protect the inkjet nozzle plate and prevent corrosion. Another round of process control is done subsequently to ensure the process's quality is consistent.

4. Delivering 100% Quality

After electroforming and plating are done, every nozzle is checked with an image analyzer that measures all the holes with submicron accuracy. It also detects any disturbance of the holes which might lead to a bad printing performance.

After this, the products are ultrasonically cleaned and packaged under clean room conditions before shipping.

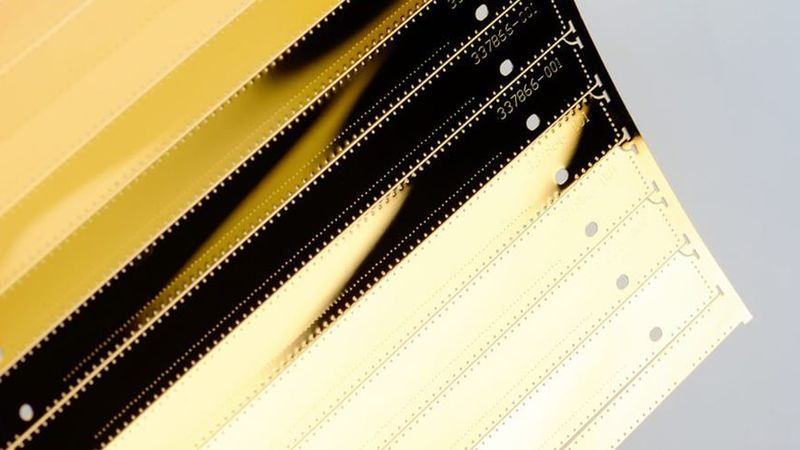

5. Traceability of nozzle plates by laser marking and data sharing

To provide the customer with unique and valuable tracking data, the nozzle plates can be laser marked with a unique text or code. These codes can be read by our customers with scanning equipment and are vital for traceability and constant improvement. Customers can also read data regarding the specifications of the hole, for example, size and pattern. This helps customers determine the effect of a certain inkjet nozzle on the printed pattern, helping them learn and improve!

Using Electroforming technology to produce inkjet nozzle plates provides several advantages, including greater accuracy and detail in the printing process. The precise contours and dimensions of the nozzles are reliably reproduced with consistently high tolerances. Furthermore, the combination of different metals allows manufacturers to achieve the desired level of hardness, wear resistance, and corrosion resistance for their nozzle plates. Finally, electroforming offers a low-cost and highly efficient manufacturing process, reducing production times and costs significantly.

To learn more about Electroforming and how it can benefit your application, download Whitepaper Electroforming here.