Sustainable kerosene: accelerating production on an industrial scale

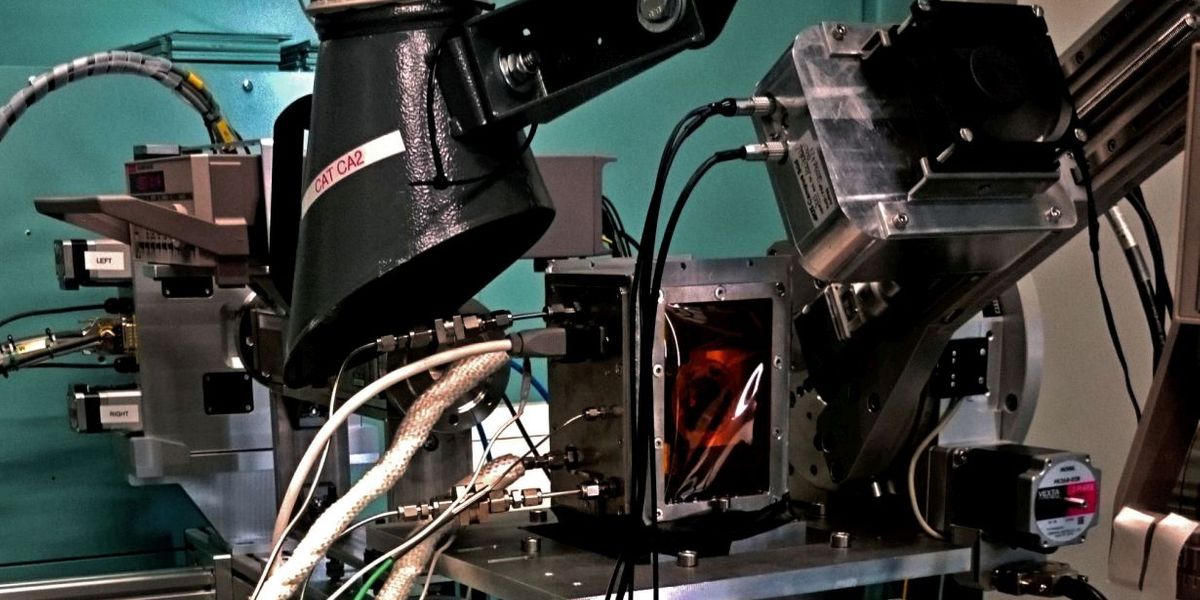

In the international CARE-O-SENE project, researchers are developing tailor-made Fischer-Tropsch catalysts for the production of sustainable kerosene. (Photo: Tiziana Carambia)

Sustainable fuels are based on green hydrogen and carbon dioxide - and should make a significant contribution to decarbonising sectors such as aviation, where fossil fuels are particularly difficult to replace.

The Federal Ministry of Education and Research (BMBF) is funding the international research project CARE-O-SENE (Catalyst Research for Sustainable Kerosene) with 30 million euros. It aims to improve the production of sustainable kerosene on an industrial scale. For this purpose, the network partners, including the Karlsruhe Institute of Technology (KIT), are developing tailor-made catalysts in order to further develop the Fischer-Tropsch synthesis (FTS) established in fuel production for the use of renewable energy sources.

With a share of more than 80 percent, fossil fuels are still by far the most important raw material for fuel, heating and the chemical industry (source: International Energy Agency, IEA). Sustainable fuels are based on green hydrogen and carbon dioxide - and should make a significant contribution to decarbonising sectors such as aviation, where fossil fuels are particularly difficult to replace. In the CARE-O-SENE project, seven South African and German project partners are therefore researching next-generation Fischer-Tropsch catalysts.

Tailor-made catalysts for the Fischer-Tropsch synthesis

The focus of the application-oriented project is the development of resource-saving catalysts for the Fischer-Tropsch synthesis. In this process, hydrogen and carbon monoxide are converted into hydrocarbons and water under high pressure and high temperatures. The slightly further modified hydrocarbons are the basis of kerosene. Sustainable kerosene is obtained in this way by using green hydrogen and carbon dioxide from biogenic sources or by separating it from the air (direct air capture).

"The catalysts have to become more efficient, more selective, and more durable," says Professor Jan-Dierk Grunwaldt from the Institute for Catalysis Research and Technology (IKFT) at KIT and Chairman of the Research Using Synchrotron Radiation Committee. To develop an optimal design, he and his team are investigating the structures and behavior of the cobalt catalysts used in the FTS under real process conditions - at over 200 degrees and a pressure of more than 20 bar. "We want to understand this in detail so that we can then develop tailor-made catalysts," says Grunwaldt.

For the investigations, the team uses synchrotron research methods: They use high-energy photons to examine the chemical state of the individual metal particles using X-ray absorption spectroscopy on the one hand and the structures of the entire catalyst using X-ray diffraction on the other. "This means that for the first time we can watch FTS catalysts at work during operation, right down to the molecular level," says Dr. Anna Zimina, head of the CATACT measurement line at the KIT Light Source.

The measurements not only provide information about disruptive structural changes that can occur during the chemical reaction and reduce the yield of the target product. The resulting data is also incorporated into theoretical models and sustainability calculations. On this basis, the researchers can make predictions about how the catalyst will change and what adjustments are necessary to make the industrial process stable, ecologically sustainable and economical. “Nowadays, theoretical calculations allow us to map the molecular processes to catalysts and thus to better understand them. This then helps to make predictions for better catalysts,” says Professor Felix Studt, head of the Theoretical Catalysis department at IKFT.

The KIT receives about five million euros from the funding of the BMBF. Part of this goes to the University of Cape Town as a subcontractor.

Goal: to produce decentrally and more selectively and on a larger scale

The scientists involved in CARE-O-SENE are convinced that regions such as South Africa, in which solar and wind energy is available reliably and over a long period of time for the production of green hydrogen, offer great potential for producing green kerosene either decentrally in modular systems , but also to produce on a larger scale. "We want to leverage this potential with this project and our strong consortium partners and increase the yield," says Grunwaldt.

About CARE-O-SENE

The BMBF funds CARE-O-SENE with 30 million euros. In addition, the industrial consortium partners are contributing ten million euros. Seven partners from South Africa and Germany are involved in the research project, which is an important component of the federal government's national hydrogen strategy. The coordination lies with the integrated chemical and energy company Sasol and the Helmholtz Center Berlin for Materials and Energy. As the third major partner, KIT is involved with the Institute for Catalysis Research and Technology and the Institute for Industrial Management and Production. Other partners are Ineratec GmbH, a KIT spin-off, the University of Cape Town, with which KIT has had close ties for years,

Further information:

Search for articles and topics on Wevolver

Tags