From Nanomaterials to Multi-Material Circuits: The Future of 3D Electronics Printing

New electronics printing technologies enable the production of miniature, high-performance 3D electronic devices, with nanomaterials being key to the process

Photo by Opt Lasers on Unsplash

3D electronics printing is a rapidly growing area of electronics production that combines nanotechnology, elements of additive manufacturing, and nanomaterials. These nanomaterials are inks or viscous pastes that contain carbon, metallic, semiconductor, or ceramic nanoparticles that provide desirable electrical properties.

While this area of electronics printing can be considered different to 3D printing proper—printed circuits can have multiple layers, but typically have a limited Z-axis—it borrows many features from other types of additive manufacturing. For example, printheads are operated via ultra-precise computer numerical control (CNC) on a gantry system. On the other hand, nanomaterials for electronics are often printed using techniques that are less common in other areas of industrial or consumer 3D printing, such as dispensing, direct ink writing, aerosol jet, or drop-on-demand inkjet.[1]

One of the most important elements of 3D electronic printing, besides the use of highly innovative nanomaterials, is the use of multi-material circuits. 3D electronics systems can provide the ability to print multiple materials in a single circuit via multi-nozzle setup or the rapid changeover of material cartridges within a single-nozzle setup. The combination of conductive nanoparticle inks and pastes (and other materials) can lead to next-generation electronic possibilities.

The Role of Nanomaterials in 3D Electronics Printing

Nanomaterials are crucial to the development of 3D electronics printing applications because they allow electrically functional materials like silver to be manipulated and arranged in an ultra-precise manner that would not be possible in other material forms.

In short, nanomaterials consist of two main components:

An easily printable matrix material. In extrusion printing, this might be an ordinary thermoplastic polymer; in dispensing it may be a glycol or glycol ether, for example.

A significant concentration of nanoparticles. These are the critical functional ingredients of the nanomaterial and may be of a material such as silver, copper, or carbon.

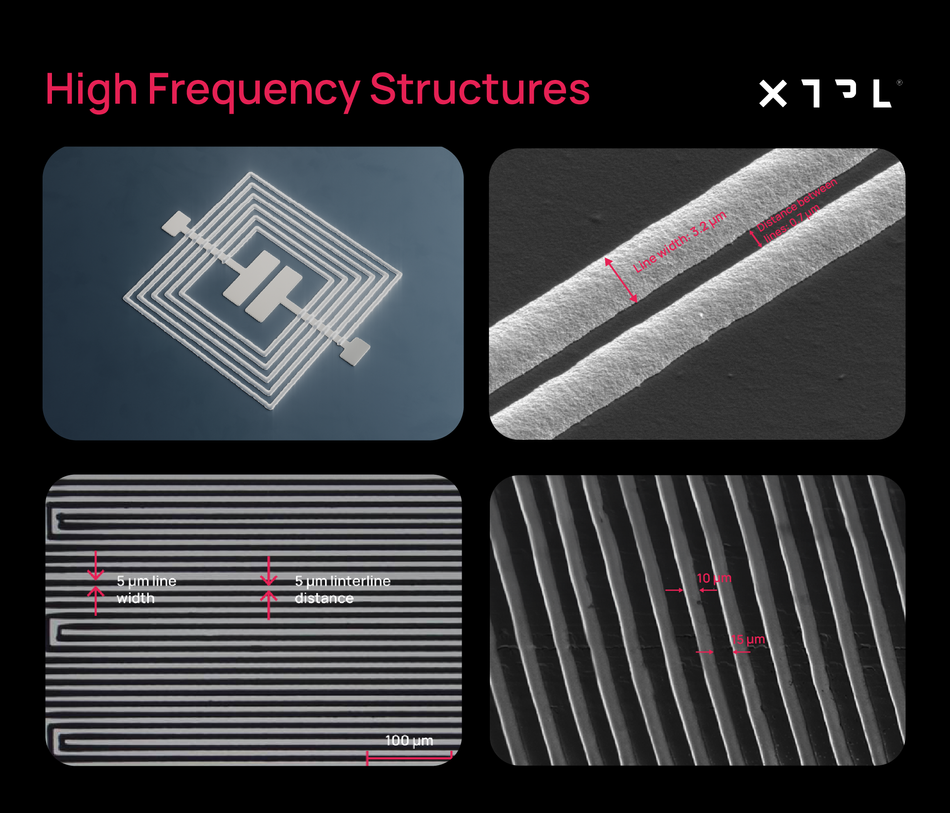

Nanomaterials such as silver inks and pastes are highly beneficial in 3D electronics printing technology due to their high conductivity, their ability to be printed through ultra-fine dispensing, aerosol, and other printing techniques, and their adhesion to various substrates. Silver nanoparticles enable fine, precise circuit patterns for applications like RFID antennas, touchscreens, and flexible sensors. Additionally, the concentration of nanoparticles can be varied to produce nanomaterials with different electrical properties and viscosities.[2]

Compared to traditional etching methods, nano inks minimize material waste and enable scalable, cost-effective, miniaturized manufacturing. Special nano-engineered formulations can also enhance the oxidation resistance and mechanical flexibility of the printed components, which can be useful in applications like wearables, medical devices, and Internet of Things (IoT) technologies.

Multi-Material Circuits: Expanding the Horizons

Multi-material circuits are advantageous because they enhance device functionality by integrating different material properties in a single fabrication process. For instance, combining conductive and insulating materials enables complex interconnects without additional processing steps. This is particularly beneficial in advanced electronics applications like flexible hybrid electronics, microfluidics, and semiconductor packaging.

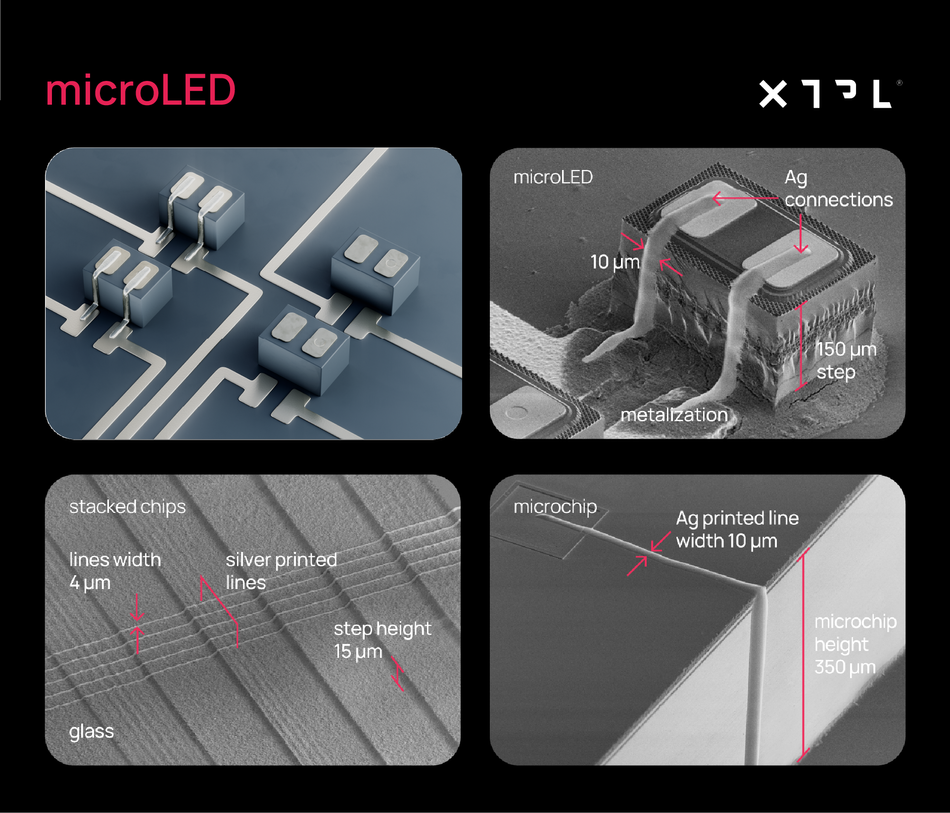

XTPL's Ultra-Precise Deposition (UPD) technology enables multi-material circuit printing by allowing precise deposition of conductive silver inks and pastes at the microscale and offering a rapid material changeover via its cartridge system. Other printable materials include dielectrics, photoresists, and quantum dots, while XTPL can also develop novel nanomaterials alongside customers to discover new applications. Furthermore, multiple UPD printheads can be operated simultaneously for multi-material dispensing.

UPD’s capability to print on various substrates, including flexible, transparent, and rough-textured ones, and even on vertical substrates using its high-viscosity Ag Nanopaste CL85, supports the development of 3D devices like next-generation wearable electronics, high-density interconnects, and custom microsensors.

The Future of 3D Electronics Printing

3D electronics printing is on course for a bright future as nanomaterials, multi-material circuits, and ultra-precise deposition techniques continue to evolve. The integration of conductive inks, dielectrics, and novel substrates will enable the development of flexible, miniaturized, and highly efficient electronic devices.

With the emergence of sub-micron dispensing technologies and an expanding nanomaterial range, applications in areas like wearables, medical devices, and IoT will accelerate and broaden. Additionally, innovations in deposition methods, such as XTPL’s UPD, will continue to enhance manufacturing precision through its dispensing of ultra-fine traces. In the future, fully functional 3D printed electronic systems—combining circuitry, sensors, and even power sources—may become standard, while the use of cutting-edge printing technologies on production lines will enable such devices to become mainstream.

Resources

[1] Persad J, Rocke S. A survey of 3D printing technologies as applied to printed electronics. Ieee Access. 2022 Mar 8;10:27289-319.

[2] Apmann K, Fulmer R, Soto A, Vafaei S. Thermal conductivity and viscosity: Review and optimization of effects of nanoparticles. Materials. 2021 Mar 8;14(5):1291.