Highly Accurate Object Recognition: MIPI Serialization ICs in Camera-Equipped Robotic Systems

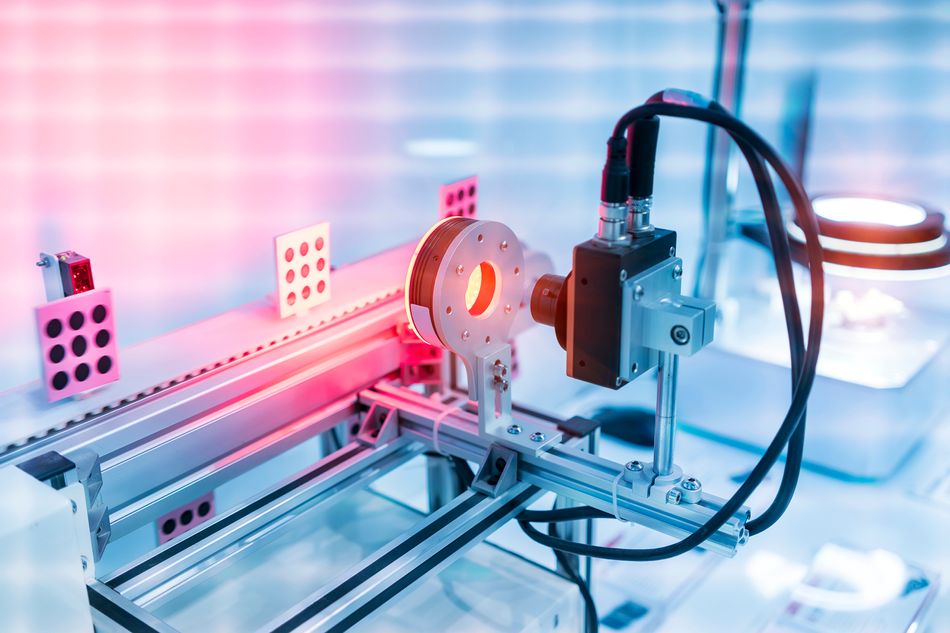

Camera-equipped robotic systems serve as key expansion components within this industry because they improve efficiency and accuracy across multiple fields, including manufacturing, healthcare, logistics, and autonomous vehicle development.

Introduction

The Robotics market is experiencing rapid growth globally, with the market value expected to reach $189.3 billion by 2027 [1]. Advancements in automation and AI-powered vision systems drive this progress. Camera-equipped robotic systems serve as key expansion components within this industry because they improve efficiency and accuracy across multiple fields, including manufacturing, healthcare, logistics, and autonomous vehicle development. These systems use high-resolution imaging and real-time data processing to accomplish tasks that demand precision and adaptability.

However, despite their potential, several challenges hinder the performance of these systems. High latency decreases operational efficiency; low-resolution imaging contributes to industrial defect detection errors. Short and inflexible cables, electromagnetic interference (EMI), and high power consumption negatively impact conventional camera systems. These factors influence the functionality and reliability of the systems. Addressing the challenges is essential for achieving the full potential of vision-equipped robotics.

Silicon Line, a leading provider of high-performance semiconductor solutions, has developed their Mobile Industry Processor Interface (MIPI) SerDes Integrated Circuits (ICs) to overcome these challenges. These ICs transport native high-resolution images with extremely low latency while allowing longer cable lengths without degrading signals. Silicon Line’s MIPI SerDes ICs enable camera-equipped robotic systems to deliver improved imaging performance while processing data in real time. This results in enhanced operational efficiency, making them more adaptable to industry requirements.

Challenges in Camera-Equipped Robotic Systems

Robotic vision systems require solutions to multiple challenges for seamless operation in industrial environments. Some of the most common challenges include:

High Latency:

The main operational problem arises from high latency, which causes delays that affect real-time decision-making processes. Applications such as autonomous navigation systems and robotic-assisted surgery require prompt decision-making; even a fraction of a second can lead to suboptimal outcomes.

Low Resolution:

Another challenge that demands immediate attention is implementing high-resolution imaging capabilities. Using low-resolution cameras in industrial robots substantially increases inspection errors, affecting product quality and driving costs. Compressed image data further reduces clarity to the extent that it hinders the effectiveness of AI-based defect detection algorithms. For instance, semiconductor manufacturing experiences financial losses because imprecise imaging can produce defective products.

Short and Inflexible Cables:

Cable limitations also present another significant problem. Transporting high-resolution images requires a very high bandwidth, which limits cable lengths and leads to thick and rigid cables. These cables limit the mobility of robotic arms and other vision-equipped robots, making them difficult to install and maintain. Traditional cables add weight and stiffness to the system, restricting the speed and agility needed for robotic systems to adapt to dynamic environments. The need for 3D camera capability in robotic systems also leads to an increase in cable complexity.

Electromagnetic Interference (EMI):

EMI can also degrade the image quality and hinder AI-driven analysis. Manufacturing environments with several electronic devices are prone to interference, leading to inaccurate object recognition and errors in automated processes, quality control, and safety systems.

High Power Consumption:

High power usage, especially in battery-operated robotic systems, is also a primary concern, as energy-intensive vision systems contribute to more significant operational costs and sustainability challenges. Rectifying these issues is essential for optimizing the efficiency and reliability of robotic vision applications.

These challenges affect robotic systems' efficiency and reliability, restricting their potential applications. Overcoming these issues is crucial for industries looking to take full advantage of camera-equipped robotics.

Silicon Line’s MIPI SerDes ICs: A Solution to Camera-Equipped Robotic Challenges

Silicon Line’s MIPI SerDes ICs offer the most efficient solution to these challenges by leveraging advanced serialization and deserialization techniques to optimize high-speed data transfer while maintaining signal integrity. These ICs utilize the industry standard MIPI D-PHY interface, ensuring compatibility with a wide range of imaging and processing components while delivering robust performance in high-speed data transmission applications. These ICs reduce latency by enabling real-time transfer of uncompressed and unconverted high-resolution images, keeping robotic systems in a position to make accurate, split-second decisions within automated navigation and robotic surgical treatments.

These ICs also enhance image recognition and support ultra-high-definition image transmission without compression, preserving crucial details for defect detection and quality control through AI. They increase the strength of Machine learning (ML)/ Deep Learning (DL) algorithms for detecting defects by eliminating lossy image processing. Thus increasing the accuracy of inspections on industrial sites such as semiconductor manufacturing and precision assembly lines.

Silicon Line’s ICs overcome the cable's limitations by supporting optical and copper based transmission over long distances and reducing cable thickness and weight. The serialization process means the 10-wire MIPI D-PHY interface is serialized to just two wires or one optical fiber. The latest Silicon Line products can also transport dual camera images over the same single fiber or two copper wires. The ICs facilitate greater robotic mobility, flexibility, and accuracy.

Additionally, Silicon Line’s extremely low-power circuit design saves power, making vision-enabled robotic systems more sustainable and cost-effective. Their compatibility with various AI & edge computing platforms ensures seamless integration, using real-time data analysis and decision-making processes in robotics applications across industries.

Real-World Applications of MIPI SerDes ICs in Robotics

Silicon Line’s MIPI SerDes ICs have several applications across various industries. Here are a few examples:

Humanoid Robotics:

Humanoid robots with high-resolution cameras need lightweight image processing to frequently perform complicated tasks such as navigation and object manipulation. Implementing MIPI SerDes ICs allows these robots to operate with greater precision and responsiveness in industries and healthcare. These ICs aid humanoid robots in improving interaction with humans in service robotics and healthcare for elderly care applications.

Surgical Robotics:

In medical robotics, ultra-high-definition imaging is required for minimally invasive procedures. MIPI SerDes ICs allow transmitting real-time images, giving surgeons clear and precise visuals during operative procedures. This dramatically increases accuracy and patient safety, especially in delicate procedures such as neurosurgery or robotic-assisted laparoscopy.

Factory Automation and Quality Control:

Manufacturing plants employ vision systems for the detection of defects and quality control. Integrating high-resolution imaging with AI-based analysis decreases defect rates significantly. MIPI SerDes ICs allow high-resolution native data transmission, enabling manufacturers to implement automated inspection systems with increased precision and reliability. This improves productivity and reduces material waste, resulting in cost savings and enhanced sustainability.

Autonomous Guided Vehicles (AGVs)

AGVs are crucial for logistics and warehouse automation, where real-time navigation and obstacle detection are essential. High-speed image transmission makes AGVs move efficiently, reducing the risk of collisions and enhancing overall workflow efficiency. Silicon Line’s MIPI SerDes ICs increase the performance of these vehicles by enabling real-time data processing and longer, flexible cable lengths.

Collaborative Robots (Cobots)

Cobots increase productivity, precision, and safety by working alongside human operators. They need real-time object detection and decision-making, requiring high-resolution data transfer and real-time handling. Silicon ICs, especially the MIPI SerDes ICs, enhance cobot's efficiency and reliability through high imaging resolution, reduced latency, and low power dissipation. This enables cobots to work flawlessly in manufacturing, healthcare, and logistics, where adaptability and high accuracy are paramount.

Conclusion:

Camera-equipped robotic systems are reshaping industries, but challenges like high latency, low resolution, inflexible and short cables often limit their potential. The advancement in silicon IC technology, especially MIPI SerDes ICs, has significantly transformed the performance of camera-enabled robotic systems. These innovations have resolved the key issues associated with conventional systems. These ICs have improved the performance and reliability of robotics in almost all sectors by allowing high-speed data transmission, real-time image processing, and energy-efficient operation.

Continuous advancements in semiconductor technology will shape the future of robotics. Developing ultra-low power ICs, AI-optimized processors, and edge-computing solutions will further enhance the autonomy and efficiency of the robotic systems. Furthermore, integrating 3D imaging, hyperspectral vision, and neuromorphic computing will allow robots to perceive and interpret their environments accurately.

With industries moving towards intelligent automation, the fusion of the latest silicon ICs and AI-driven robotics will result in more advanced, adaptable, and sustainable solutions. These innovations will increase the functions of camera-based robotic automation, transform the future of robotics and automation, and enhance productivity, safety, and operational efficiency across diverse sectors.

Silicon Line invites professionals from all stakeholders to explore these advancements further.

References:

[1] Advantech, “Enabling Smart Robotics with Single-Board Computing.”

[2] P. Lu, K. Yuan, and W. Zou, “A High Performance Low Power Consumption Robot Vision System,” in Third International Conference on Natural Computation (ICNC 2007) Vol V, IEEE, Aug. 2007, pp. 171–175. doi: 10.1109/ICNC.2007.42.

[3] Silicon Line, “Silicon Line.” Accessed: Feb. 21, 2025. [Online]. Available: https://www.silicon-line.com/