How to Select the Best Temperature Sensors for Your Smart Project

Remote temperature monitoring systems provide critical insights for IoT applications across many industries, including real estate, manufacturing, and healthcare. Early adopters are already seeing measurable ROI from automatic temperature monitoring in terms of increased productivity and more.

Temperature sensors are the “eyes and ears” of remote temperature monitoring systems.

This article was first published on

www.disruptive-technologies.comRemote temperature monitoring systems provide critical insights for IoT applications across many industries, including real estate, manufacturing, and healthcare. Early adopters are already seeing measurable ROI from automatic temperature monitoring in terms of increased productivity, decreased costs, and lower risk.

Temperature sensors are the “eyes and ears” of remote temperature monitoring systems. They continuously, automatically collect and aggregate temperature data for analysis and real-time decision making.

Just as temperature monitoring systems have advanced in recent years, so have the temperature sensors that power them. Today’s most advanced sensors are more affordable and easier to install than ever before. With simple and scalable wireless temperature sensors, you have the freedom to experiment with new temperature monitoring applications without a massive up-front investment.

How do you choose a temperature sensor solution?

Working with IoT applications like remote temperature monitoring systems requires some planning and experimentation. Below are critical questions to consider as you plan your temperature sensor project. They’re designed to help you use temperature data as part of your daily operations and gain a rapid return on your investment more rapidly.

Temperature sensors aren’t a one-size-fits-all solution. Understanding your environment is key to a temperature sensor implementation that meets your goals. Your answers to these questions will determine:

- How many sensors are appropriate for your implementation?

- How densely should sensors be installed?

- What specific setup for temperature sensors is required (such as angle of placement or other installation techniques to match requirements for thermal mass)?

- How will temperature data from sensors be integrated with analytics and monitoring systems?

1. Where is the specific location you want to measure?

Understanding what you want to measure and the conditions that impact temperature will help you understand how many data points — and thus, how many temperature sensors — you’ll need to accomplish your goals. For example:

- Will sensors be near windows? The temperature on a window sill will be different than the temperature in the middle of a room. For ambient temperature monitoring, you may need reference sensors to compare different locations.

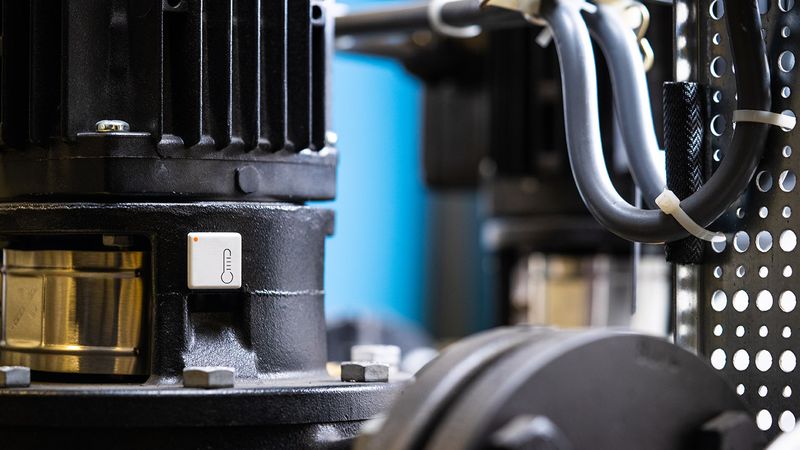

- Will temperature sensors be placed on metal, on heated pipes, or on other equipment? In an equipment room, for example, a sensor can pick up the heat signature of an asset next to the asset you are trying to measure – instead of your target.

- Will sensors be near people? For example, temperature sensors under a desk will be different when a person is present vs. when the workstation is unoccupied.

- Will the cellular connection need to be underground? If so, remote temperature sensors may need special attention for network access. Sensing solutions can be attached to Ethernet, if available, or to a 4G cellular network for wireless temperature sensing.

2. How often will you want to check temperatures?

Depending on your project, you may want to record frequent, minute temperature fluctuations, or you may want to see an average result over an extended period of time.

Keep in mind, assets with lower thermal mass don’t hold heat, so their temperatures fluctuate more frequently than assets that have higher mass. In contrast, assets with higher thermal mass provide a slower response to changes and therefore provide smoother data results. This can be important to consider for fault finding on larger objects or where quick response is required.

This difference can impact temperature measurements of locations such as walk-in freezers or cold cabinets and drive how frequently you must check them.

3. What are your acceptance criteria?

Do you have compliance or other reporting requirements that mandate specific margins of error for temperature sensitivity? If so, what level of temperature sensitivity do you need to make decisions and stay within compliance?

Are you looking to measure absolute temperature? Or, is it more important for you to measure relative temperature to understand changes and comparisons? Do you need a reference temperature sensor for the relative comparison?

4. How will you act on the findings?

Before beginning any temperature monitoring project, work with your team to determine what you’re trying to achieve. How are you going to use the data you collect and analyze?

Temperature sensors can provide backup data to confirm suspicions you already have. For example, you may suspect that energy is being wasted due to poor temperature control. Or, your building tenants may be complaining about temperature inconsistency and you need the data to confirm the problem.

Even more exciting is the potential for temperature sensors to tell you things you never would have known. For example, when temperatures on equipment unexpectedly spike, the change can indicate a malfunction or an impending problem. If that happens, what will you do next? Ask yourself:

• What teams and systems need to be alerted when temperatures change?

• What actions will be triggered when temperatures change?

• How quickly will you need to respond to those changes?

Give yourself the freedom to experiment

The questions above are designed to get you off to a strong start with your temperature monitoring project, but you should also make sure you leave some room to experiment. IoT is a nascent industry, with new applications and technologies released all the time. You may find that temperature data you collect through temperature sensors give you the capacity to launch new projects you didn’t originally anticipate.

Small and lightweight, Disruptive’s mini-sensors allow you to place temperature sensors in high density and test new locations and configurations. You can easily move sensors to compare data so you can continue to adapt your solution.

Disruptive Technologies and our partners are here to help you design a temperature sensor solution that fits your unique environment so you can meet your goals – and allows you the freedom to test and learn.

For inspiration, see how temperature sensors are being used in a wide range of applications and use cases.

***written in collaboration with my colleague and DT Founder, Erik Fossum Færevaag.