One Software Simplifying Robotic Programming for Every Industry

Empowering users with zero programming knowledge: building a robust manufacturing network to enhance industry resilience.

Introduction:

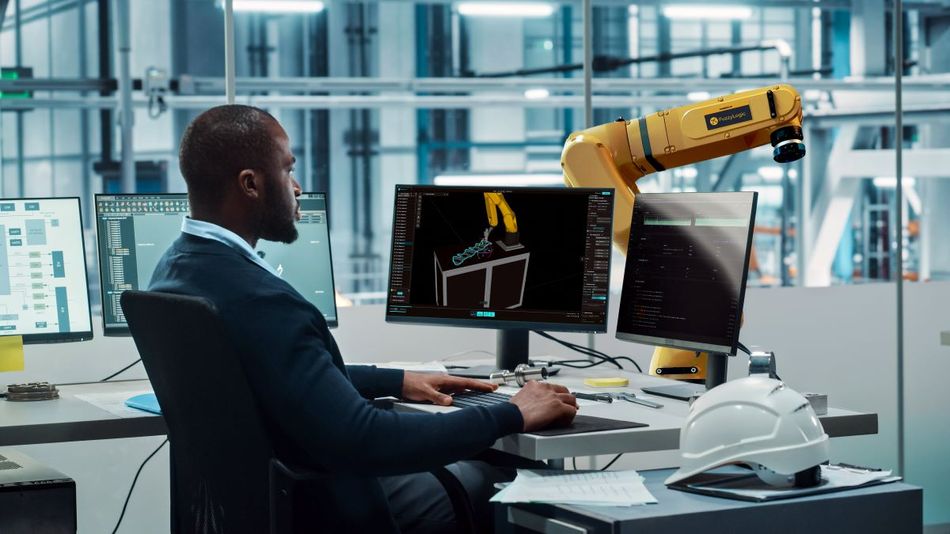

Fuzzy Studio by Fuzzy Logic Robotics enables anyone to program and control robots thanks to its no-code, user-friendly interface. The studio significantly increases accessibility to the otherwise highly complex world of robotic-enabled automation.

What is Fuzzy Studio?

If you're a project engineer, Fuzzy Studio helps you design robotics systems. Making your projects easier to manage and more efficient. For example, it can improve how automated systems in industries like manufacturing or robotics respond to varying conditions, enhancing accuracy and adaptability. Fuzzy Logic is a software toolkit for handling complex, real-world problems where answers aren't just "yes" or "no" but somewhere in between. Its foundation is fuzzy logic, a kind of logic that mimics human thought and decision-making by recognizing more than binary true or false values

Using Fuzzy Studio

Interactive Digital Twins:

Digital twins are virtual models of real systems or processes that help predict and improve their performance. Fuzzy Studio allows engineers to design and simulate robotic cells in a virtual environment, mirroring the exact specifications and operations of real-world systems.

During planning phases, digital twins are crucial, providing a platform to experiment and optimize workflows without the physical constraints or costs associated with real-world testing. This feature enhances precision in deployment and reduces setup times and potential operational disruptions, ensuring that systems are optimized for performance from day one.

Advanced Trajectory Generation:

Fuzzy Studio's trajectory-generating feature, which automates the programming of complex robot movements straight from CAD models, is another significant breakthrough. For jobs demanding extreme precision, including deburring, grinding, or complex assembly operations, this feature is essential.

Programming these paths often is time-consuming and requires specialized knowledge. But Fuzzy Studio streamlines this procedure, enabling users to easily create accurate and efficient trajectories that increase manufacturing processes' speed and quality. With little to no specialized programming knowledge required, robotic automation becomes more widely available and allows for quicker modifications to production lines in response to changing market needs or production objectives.

Key Technical Features of Fuzzy Studio:

Advanced Technical Capabilities of Fuzzy Studio: In-depth Overview

1. No-Code Programming:

Fuzzy Logic’s software offers a no-code method of robotic programming, enabling users who are not familiar with standard programming techniques to engage and implement industrial robotics.

Example:

At "Company X," a small non-destructive testing company, technician Alex uses Fuzzy Logic's software to automate the inspection process:

Designing the Workflow:

Alex selects his industrial robots on the robot library and the same for its tools. Then he adds his work piece to the 3D scene.

Alex can now create his trajectories by using his work piece.

Simulating and Adjusting:

Alex runs a simulation to test the robot's actions.

He adjusts speeds trajectory and waypoints positions.

Deploying the Workflow:

Once satisfied with the simulation, Alex clicks "Robot connection."

The software converts the visual design into code, and the robot begins to play the exact simulation played in Fuzzy Studio.

This enables small companies to automate production or inspection quality without the need to hire specialized robotics engineers, broadening the range of businesses that can enhance productivity and innovation through automation.[1]

2. Compatibility & Integration:

A notable aspect of the software is its seamless integration with a large number of popular robotic manufacturers and external industrial devices. This compatibility ensures that Fuzzy Studio can be readily implemented with a variety of robotic hardware options without requiring major infrastructure changes.

For example, it supports equipment from leading manufacturers such as ABB, FANUC, KUKA, Staübli, Universal Robot and Yaskawa, as well as communication protocol including REST. These protocols enable easier data exchange and control across various systems. This universal compatibility is crucial for manufacturing facilities looking to enhance and diversify their automation technologies without being tied to specific brands, ultimately being a more flexible and future-proof production environment.[2]

3.Simulation & Real-Time Control :

Fuzzy Studio with Fuzzy RTOS offers dual real-time robot simulation and control capabilities, which means users can create and test robotic operations in a virtual environment before implementing them in real-life settings.

The benefits of this capability:

Risk Reduction: By simulating operations virtually, potential issues can be identified and corrected before they impact actual production, reducing the risk of costly errors and downtime.

Increased Efficiency: Testing and optimization can occur continuously and without interruption to current processes, ensuring that production lines can keep running while improvements are being made.

Faster Implementation: Since configurations can be developed and refined in a simulated environment, the transition to real-world application can be quicker and more seamless, accelerating the overall deployment of new robotic functions.

Cost Savings: Minimizing the need for physical trials reduces the wear and tear on actual robotic equipment and saves on the materials that would otherwise be used in testing phases.

Recommended reading: 5 Reasons Programming Robots is Hard

How Can Fuzzy Studio Be Applied Across Industries?

Fuzzy Studio could have a significant impact on various sectors by enabling small and medium-sized enterprises (SMEs) to automate production lines, facilitating the move towards small-batch production and custom part manufacturing. Historically, the adoption of robotic solutions for these businesses has been hindered by the high costs and complexities associated with robotic programming.

By using Fuzzy Studio, SMEs can automate complex tasks, optimize operational efficiencies, and scale production with greater accuracy and reduced labor costs. This is crucial for SMEs aiming to compete with larger corporations, providing them with the tools to innovate and expand in a cost-effective manner.

The software addresses these specific challenges by simplifying the automation process, making it more accessible and cost-effective. This is particularly beneficial in industries such as aerospace, automotive, and consumer electronics, where customization and adaptability to market demands are critical.

To quickly adjust production processes without extensive reprogramming allows companies to respond faster to customer-specific requests, enhancing overall agility and reducing lead times.

Price & Accessibility:

Cost-Effective:

With Fuzzy Studio relying less on specialized robotic programming talent, it significantly improves the budgetary sustainability of robotic integration across a range of businesses. It reduces the usual cost barriers to robotic adoption, making it a feasible choice even for industries that had previously thought automation would be too costly.

This accessibility could lead to a more rapid deployment of robotics, which in turn enhances productivity and operational efficiency, reducing long-term costs and increasing return on investment.

Reviving Industry:

BPI (France) has backed the development of Fuzzy Studio, recognising its potential and seeing it as a key instrument for European reindustrialization initiatives.[3] The ability of Fuzzy Logic to make expensive and complex robotics technology affordable and accessible fits in with larger economic initiatives meant to stimulate the manufacturing sector and increase industrial output.

Conclusion:

User-friendly software like Fuzzy Studio, adaptable to various hardware, is reshaping industrial automation. These types of software have the potential to significantly improve the industry by streamlining operations, reducing costs, and supporting small and medium-sized enterprises. With innovations like interactive digital twins, it paves the way for further advancements, promising a brighter future for industrial automation.

References

1. Robotics and Automation News. Fuzzy Logic Robotics aims to revolutionize industrial robotics with Fuzzy Studio. Available from: https://roboticsandautomationnews.com/2023/02/16/fuzzy-logic-robotics-aims-to-revolutionize-industrial-robotics-with-fuzzy-studio/60436/

2. Robotics Tomorrow. Fuzzy Studio: The Robotics Software for Everyone Is Now Available Online! Available from: https://www.roboticstomorrow.com/news/2023/04/12/fuzzy-studio-the-robotics-software-for-everyone-is-now-available-online/20399/

3. FLR. Fuzzy Studio: The Robotics Simulation Software for Everyone is Online. Available from: https://flr.io/fuzzy-studio-the-robotics-simulation-software-for-everyone-is-online/