Recycling wind turbines and modular robots: The winners of the Circular Economy Challenge.

The winning teams each receive manufacturing and business support to take their design to the next level.

Image credit: Stock/Intermode

Wevolver, in partnership with Growth Garage, the business accelerator from Mitsubishi Chemical Advanced Materials, Mitsubishi Chemical Europe, and Mitsubishi Chemical Methacrylates, invited engineers, designers, entrepreneurs, startups, companies, and students to submit their ideas, technologies, and products as part of the 2022 Circular Economy Challenge.

The challenge looked for innovators throughout the plastics circular economy who want to make use of advanced low carbon footprint engineering plastics or have developed innovative recycling technologies for advanced engineering plastics.

The challenge was open to participants in two key areas: 1. Recycling Technology and 2. Products & Parts.

The Circular Economy Challenge received over 60 entries from 17 countries. The Wevolver community vote had over 700 votes.

Congratulations to all finalists and winners!

The winner of the Circular Economy Challenge

Category 1: Recycling Technology

Jeosal Materials Research Corporation

Canada

Jeosal Materials Research Corporation is a developer of economically viable, and ecologically sustainable solutions for the recycling and reuse of fiber-reinforced plastics from various sources including the automotive, aerospace, marine, and construction markets. Recovered products are channeled towards new applications in original or new markets.

“Our business model is designed specifically for the recycling of fiberglass from marine vessels and reuse of the recovered products. It has the added advantage of successful deployment for fiber-reinforced plastics from other sources.

In this model, we rely on specifically modified and enhanced recovered fibres and resin powder for unusual end-uses to ensure an economically viable and environmentally responsible venture,” describes Jeosal Materials Research Corporation’s CEO, Osayuki Osazuwa.

Jeosal Materials Research Corporation will receive $25,000 of support from Growth Garage and their partners to test the technology at scale and strengthen their business model.

The winner of the Circular Economy Challenge Category 2

Internode

United States

Intermode manufactures and produces small robotic vehicles which they lease to customers for the purpose of automated delivery. The robots are designed to recapture some portion of their material value at end of life for reuse in future robots.

“Coming from an automotive background, I know interior and exterior engineers can choose a huge range of different plastics to best target cost per individual component, but that can lead to a series of plastics that are individually "recyclable" but extremely difficult and cost-intensive to do so without tearing it down to small pieces.

We intend to engineer the vehicle to maximum value and performance over its life lifecycle. We've designed the vehicle to be modular to easily break it down for recycling and keep materials pure for as long as possible," explains Internode Co-founder and CEO Arnolld Kadiu.

“We'd like to investigate two different types of plastics. Structural fiber-reinforced thermoplastics to over-molded metal parts and UV stable thermoplastics to either thermoform or injection mold vehicle exteriors.”

Intermode will receive $25,000 of support from Growth Garage and their partners to build prototypes and work with the challenge partners to strengthen their business model.

Wevolver Community Vote winner

Wannes Van Laerhoven

Belgium

Wannes Van Laerhoven proposes a solution that recycles old tires and processes them into a filament suitable for 3D printing airless tires that can be used for various purposes.

“I have already done tests with a filament made from recycled car tires and the results are promising. There is good elasticity and better grip than on the other TPE and TPU filaments I have tested without the rubber from car tires. The print quality is also much better than expected and surface quality is even better than the filaments without added rubber. Even though it's 3D printed with FDM it is very hard to see the printed layers unlike the normal TPE shore 45D printed prototype.”

The airless tire can provide a good damping effect because the lattice structures used in the tire have good energy-absorbing properties. This causes a more enjoyable ride for applications in micro-mobility and mobility devices such as wheelchairs.

Wannes Van Laerhoven will receive $10,000 of support from Growth Garage and their partners to develop their idea further and create a working prototype.

Student Vote winner

Wannes Van Laerhoven also won the student prize. He will receive a further $5,000 in support from Growth Garage to develop his project, create prototypes and strengthen his business plan.

The Circular Economy Challenge finalists

The finalists of the challenge impressed the judges with their innovative designs and cutting-edge approach to the circular economy.

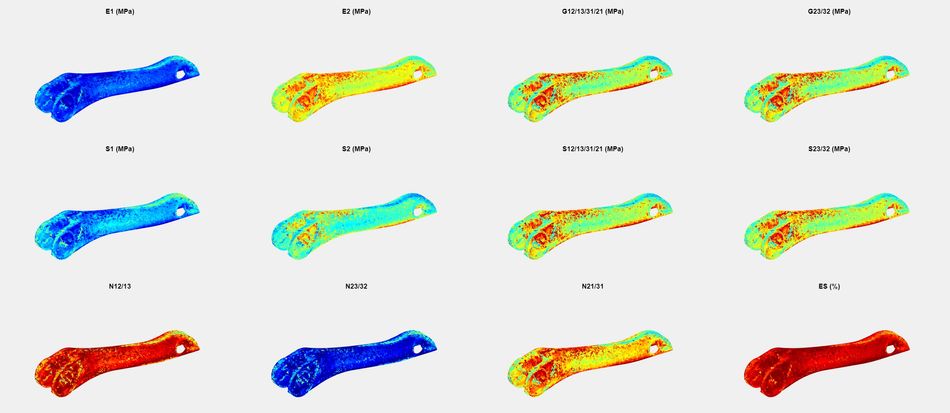

AirGo

An AI-assisted technology that accelerates the process of metal replacement reliably and quickly predicts the anisotropic properties of highly complex reinforced thermoplastic components.

Diamond Hard Surfaces

A low-temperature processing technology that enables the coating of thermoplastics such as PEEK, PEK, and Polyimide materials with a hard wear-resistant coating.

Interface Polymers

Polarfin® diblocks connect dissimilar plastics in recycled plastic blends allowing the recycling of multilayer films and mixed plastics which are currently uneconomic to recycle.

RD Physics

Remanufacturing loudspeakers using 3D printing. That means disassembling old loudspeakers and reusing the components in a new product.

BCIRCULAR

Provides a solution for the recycling of composite materials using an innovative, sustainable, energy-efficient, closed process that treats 100% of the composite materials to produce high-quality carbon fibers without releasing contaminant emissions.

3D Seed

Recycles/grinds up recycled plastic which feeds directly into 3D printers - enabling objects to be created directly from waste.

Intermix Performance Materials

A set of novel, highly potent compatibilizers to improve recycling efficiency for two of the most widely used plastic materials, polypropylene (PP) and high-density polyethylene (HDPE).

The Fotostax Motion™️

Instantly capture and print moving and 3D photos directly from your phone using a phone case printer. This product is designed to be modular and upgradeable and to use recycled materials.

Healix

Transforms used ropes and nets (HDPE and PP) from fishing and farming into pristine circular polymers for the global manufacturing supply chain.

Wevolver will follow the winners and finalists as they advance their technology and products. Sign up for our newsletter and social media to get the latest updates.

Thank you to everyone that entered the challenge, the jury, and the supporters.

About the sponsor: Mitsubishi Chemical Advanced Materials & Growth Garage

Mitsubishi Chemical Advanced Materials is a leading global manufacturer of high-performance materials in the form of semi-finished products and finished parts. The company has locations in 20 countries and more than 2,800 employees. Its specialty engineering thermoplastics and composites are superior in performance to metals and other materials and are used in a wide range of applications, primarily in the capital goods industry. The company is continuously developing new areas of applications in close cooperation with industry leaders in a wide variety of customer markets. The Mitsubishi Chemical Advanced Materials Group is well prepared to further expand its market leadership position.

Growth Garage is a business accelerator program from Mitsubishi Chemical Advanced Materials. Our mission is to support and grow new ideas using our technologies and advanced engineering materials to help tackle some of today's biggest engineering challenges. We are offering the opportunity for engineers and innovators to pitch us their ideas and receive manufacturing support and services.